Faster detection, smarter classification, and coordinated effective response – one comprehensive operational picture across sea, air, and land.

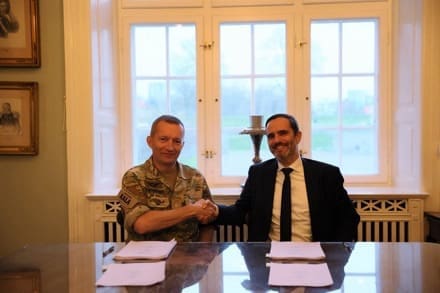

Lystrup, Denmark, 27th November 2025 – Terma A/S has completed the acquisition of OSL Technology (OSL), a UK-based leader in counter-drone security and safety systems. The acquisition marks a major step in Terma’s strategy to build market-leading capabilities in Counter-Unmanned Aircraft Systems (C-UAS) and critical-infrastructure protection.

OSL is a UK-based counter-drone and intelligent security specialist with its roots in the civil airspace domain, helping major airports and national-infrastructure sites detect, track, and manage drones and other aerial threats in complex environments. Terma brings decades of experience from the defense and security domain, supplying radar and command-and-control solutions to navies, air-defense units, and critical infrastructure operators.

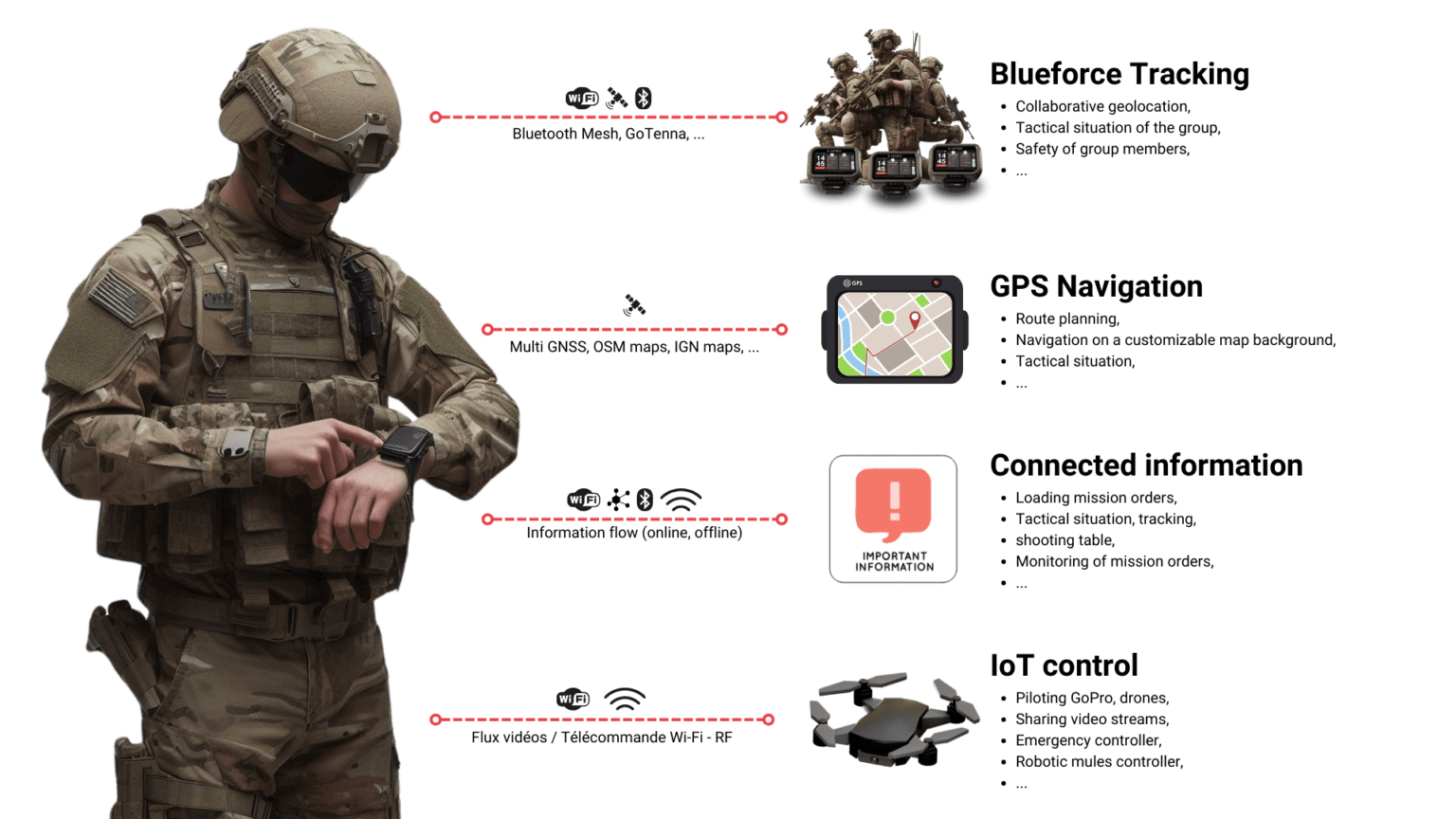

The combined team bridges civil and defense mindsets and practices into a single, end-to-end C-UAS solution that can detect, track, classify, decide, and respond to threats within seconds.

Together, Terma and OSL now combine defense-grade sensors, AI-driven analytics, and real-world operational expertise in an open, modular ecosystem. Integrating Terma’s situational-awareness heritage with OSL’s full-stack counter-drone suite provides continuous coverage and intelligent fusion across sea, air, and land – including third-party sensors and effectors – enabling one trusted operational picture that caters from the tactical to the strategic.

Henriette H. Thygesen, CEO, Terma, said, “OSL’s operational performance – from years of protecting critical infrastructure at Heathrow and other major sites – shows it delivers where it matters most. Paired with Terma’s multi-domain capacity, built on decades of delivering situational awareness and defense-grade command-and-control, and further informed by partnerships in Ukraine, we now offer one of the most comprehensive C-UAS suites on the market, helping to set a higher standard for protecting people, airspace, and critical infrastructure. This is not only about Denmark here and now; it delivers a strong, comprehensive C-UAS solution that can contribute to European flagship projects such as the proposed EU drone initiative.”

For airport authorities, critical-infrastructure operators, and defense customers, the combined offering provides one integrated C-UAS picture – with rapid deployment and immediate operational effect.

“Joining Terma is an extraordinary opportunity for OSL and our customers. Terma’s multi-domain expertise together with our C-UAS platform and agility create unmatched depth of capability – from sensor to decision to response. It means faster detection, smarter classification, and precisely coordinated action. It’s the perfect combination of innovation and assurance”, said Mark Legh-Smith, CEO, OSL.

Terma and OSL will serve customers worldwide in C-UAS and critical-infrastructure protection, leveraging OSL’s operational excellence and Terma’s technology base and global reach to deliver fast, reliable, and scalable solutions across civilian and defense sectors.

MW&L Capital Partners acted as exclusive financial advisor and Kromann Reumert, Addleshaw Goddard and Deloitte acted as legal- and tax-advisors to Terma.

Cavendish acted as exclusive financial advisor to OSL with Bird & Bird acting as legal advisor.