HLC Industries Inc is offering an in-stock program of Solution Dyed Cordura Fabrics in both 500D and 1000D, in the following colors: Coyote 498 / Black / Ranger Green / Tan 499 / Wolf Gray.

Please contact: peter@hlcindustries.com

HLC Industries Inc is offering an in-stock program of Solution Dyed Cordura Fabrics in both 500D and 1000D, in the following colors: Coyote 498 / Black / Ranger Green / Tan 499 / Wolf Gray.

Please contact: peter@hlcindustries.com

Brand acquisition bolsters Milliken’s capabilities to include fleece, performance textiles for consumer, workwear and military outdoor apparel

SPARTANBURG, S.C. — Milliken & Company (“Milliken”), a global diversified manufacturer with more than a century and a half of textile expertise, today announced that it signed a definitive agreement to acquire Polartec, LLC (“Polartec”), a strong global brand known for its innovative performance textiles for outdoor and military apparel, from Versa Capital Management, LLC (“Versa”). The acquisition is expected to close in June. Financial terms of the transaction were not disclosed.

Headquartered in Andover, Massachusetts, the Polartec brand carries a respected portfolio of fabric technologies for outdoor apparel, from performance-driven and consumer-focused textiles, to flame-resistant, workwear and military-grade fabrics. The addition of the Polartec brand—particularly its outdoor and fleece textiles—rounds out Milliken’s comprehensive portfolio, allowing the company to deliver unprecedented access to a range of performance textiles for consumers, industrial workers and military personnel around the world.

“Polartec brings a wealth of new and respected outdoor textile expertise to complement Milliken’s strengths,” shared Halsey Cook, president and CEO of Milliken & Company. “The strategic acquisition broadens our textile capabilities with a product offering to now include fleece and soft-shell outerwear, among others, allowing us to grow in new and exciting spaces.”

“With more than 150 years of textile innovation, Milliken is the best possible ‘natural owner’ of a brand with Polartec’s pedigree. I look forward to supporting the integration,” said Polartec CEO Gary Smith. “I’m grateful to Versa Capital Management for their support in realizing Polartec’s full potential, and I’m extremely proud of the global Polartec team for their dedication and hard work that put the company in the position it is in today.”

“We look forward to growing Polartec’s strong brand at Milliken,” said Jeff Price, president of Milliken’s Performance and Protective Textiles Division. “Polartec expands our regional manufacturing reach and grows our technological expertise, enabling us to further deliver innovative performance textiles to the global market.”

“Milliken provides the perfect platform to ensure the continuation and acceleration of the success of the Polartec brand after years of complex and transformative business repositioning by Gary Smith and his team,” said Greg Segall, CEO of Versa and chairman of Polartec. “It has been a great collaboration with Gary and all of Polartec’s valued employees, and we are proud of all that has been accomplished during Versa’s ownership—notably the feat of reviving an American textile icon and powerful global brand into an enterprise equipped to succeed in today’s highly competitive markets. Milliken is the ideal long-term owner for Polartec, and we look forward to seeing the two companies achieve big things together.”

Versa acquired the assets of the former Malden Mills in 2007 through the then 101-year-old textile manufacturer’s third reorganization. Working with management, the business was transformed, renaming the company Polartec, reorienting it toward a technology- and innovation-led growth strategy, and revamping the company’s leadership, operations, manufacturing footprint and customer relationships.

The transaction is subject to customary closing conditions.

Versa and Polartec were advised by Lazard Middle Market and Sullivan & Cromwell LLP. Milliken & Company was represented by Jones Day LLP.

To learn more about Milliken’s Performance and Protective Textiles Division, visit textiles.milliken.com.

While there were several great new products at Rampart Range Day, none surprised nor impressed me more than Xion (pronounced zion) Protective Gear. Their garments have been worn for years in sports and by stuntmen, protecting from blunt trauma injuries. But now, they’ve been discovered by LE for use as a low viz crowd control suit for use in scenarios where the appearance of full riot gear might increase tensions. Naturally, the gear can be worn in any scenario where blunt force trauma is a threat.

The suits can be worn under outer garments.

Some of the garments are also FR, adding another facet of personal protection.

The secret is in their use of D3O pads which works as a non-Newtonian fluid, absorbing high energy impact, yet remaining malleable when not under force. In fact, the founders of Xion came from the stunt industry and have been working with D3O for many years on pad designs.

Xion Protective Gear products are available in North America from Rampart International.

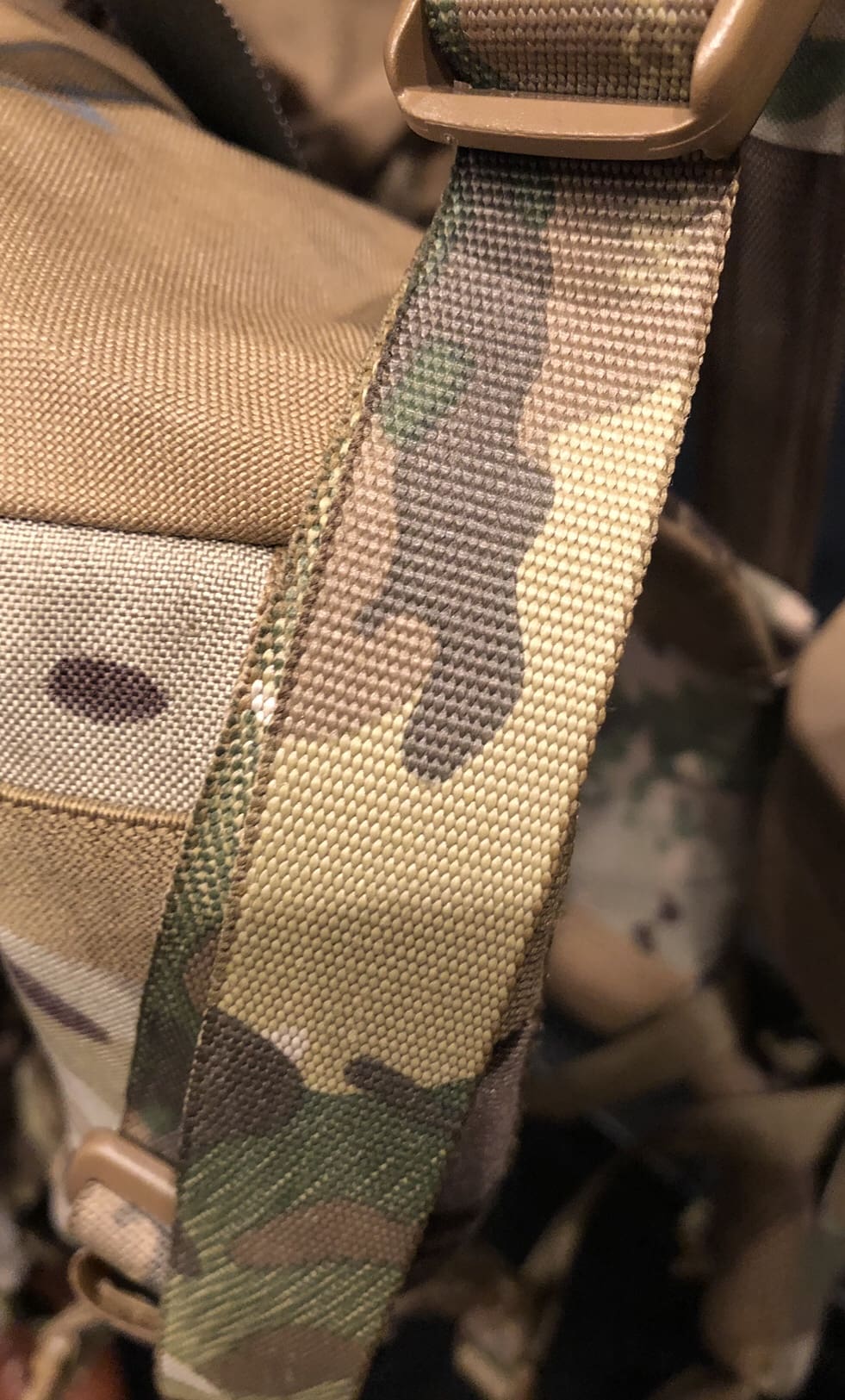

Mystery Ranch has introduced a new tale webbing to certain models. Developed in conjunction with MMI Textiles, it uses MMI’s patented CTEdge to conceal and blend the edge, making the webbing stronger and thicker than your typical 55301 MOLLE webbing which uses solution dyed yarns. This allows for better pull strength, break strength and less slip through the buckles. The 1″ version also incorporates MMI’s exclusive High Blend of MultiCam to reduce any lattering effect that only 1 repeat of the pattern causes.

Along with the increased performance of the webbing, MMI print technology improves UV and abrasion of the ink for long lasting color in the harshest of environments.

This is available on a limited basis through MMI Textiles.

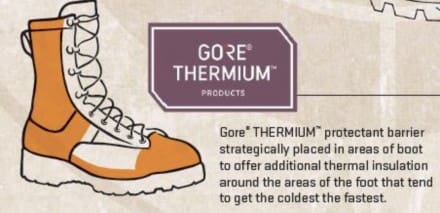

This is the first time WL Gore & Associates, Inc, makers of Gore-Tex material have shown a product made from their new lightweight Thermium insulation. It’s the new Extreme Cold Weather Boot from Belleville.

The boot features 600 grams of composite insulThe Gore Thermium is in the form of a boot insert construction, similar to the Gore-Tex membrane boot insert. However, as depicted in this graphic, the insulation is mapped, with thicker areas covering certain parts of the foot in order to ensure a better fit and protect those parts of the foot which get the coldest.

Built on the Belleville 675 platform, the boot will protect down to -20 deg F and is flight approved. In addition to the Gore Thermium Insulation, the boot also features Gore-Tex protection.

Blue Force Gear is exhibiting a version of the upcoming PLATEMINUS Ver 4 made from the new Woodland camouflage pattern ULTRAcomp fabric.

Not only does Blue Force Gear use the laser-cuttable ULTRAcomp material for their own products, it is also available for other manufacturers.

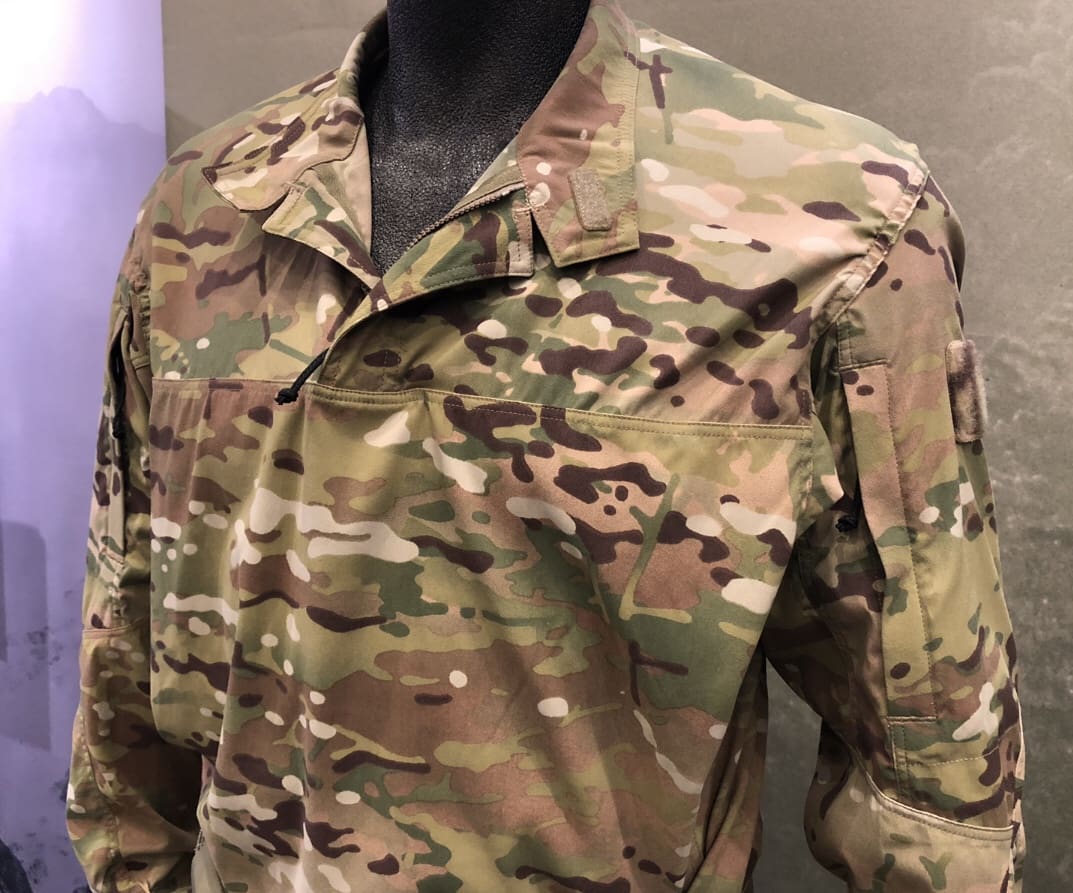

Patagonia’s Lost Arrow Project is displaying a prototype 3-season uniform. The idea is to offer a single, multi-environment, multi-season uniform solution since there have been so many calls for hot weather, jungle and swimmers specialty uniforms.

The challenge wasn’t so much in the cut of the uniform as the material. LAP selected a board short-like material which dries quickly, is highly breathable and very durable.

The concept consists of three pieces, a common pant along with Combat and Field shirts. Wear either shirt based on preference.

What’s more, unlike existing cotton-based uniforms, it can be integrated with the other components of their Military Alpine Recce System clothing.

Currently undergoing user trials in multiple environments, LAP plans a commercial launch in 2020, integrating user feedback.

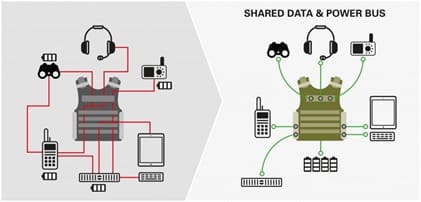

Fischer Connectors continues to protect and defend special operations personnel with the Canadian debut of a new wired tactical vest at CANSEC 2019. This fully-functional tactical vest on display in booth #525 features Fischer Freedom™ Series connectors sewn into the garment and connected to a distributed data and power bus that handles soldiers’ connectivity needs. The unique connectivity solution cuts weight from the vest while improving functionality.

Integrating a distributed data and power bus into the tactical vest eliminates the need for the external wires or break-out cables that currently weigh soldiers down.

Receptacles sewn into the vest and attached to the bus connect to devices and deliver power and signal, and a single battery pack powers all the devices. Communications gear, sensors, flashlights, cameras, viewfinders, GPS devices, and other essentials can be attached with matching plugs built directly into the device without the use of cables.

This approach to tactical connectivity is part of an overall trend to integrate more wearable technology into military gear to help reduce weight and simplify use.

Wim Vanheertum, Director of Product Management for Fischer Connectors says new connector technology is a critical element of the rapidly expanding market for wired tactical vests. “Rugged, low-profile connector receptacles sewn directly into the fabric and matching plugs built directly into devices can significantly reduce, or even eliminate, the use of cables. The award-winning Fischer Freedom™ Series connector used here has concentric rings on the receptacle that allow for 360° mating freedom, and a plug with a sealed membrane that protects the contact block with an IP68 rating.”

According to Vanheertum, sensors can be built into plugs, or plugs can be engineered directly into devices to eliminate cables entirely. The low-profile plug can also be cabled for communications gear and other devices such as cameras and video screens.

Several companies have already started building vests, devices, and sensors based on these concepts, and are testing them in multiple countries.

A SNEAK Preview of the smaller four-pin plastic version of the Fischer Freedom™ Series is available at SOFIC.. Please stop by to take a look at this unique connector series.

More information

•Fischer Freedom™ Series | Fischer LP360™for Defense & Security

• Trend paper: Emerging Trends in Wearable Technology Across Several Markets