Yesterday, I discussed Patagonia’s history of supporting SOF with clothing systems. Today, I’ll take a look at how they’ve applied that expertise in design, materials and manufacturing to offer a new concept in protection in extreme environments.

Development

When Patagonia created the original MARS almost 15 years ago, it was called Military Advanced Regulator System because it was based on their Regulator technology. Although Patagonia still produces Regulator fleece garments, many newer materials have come along.

Even during Patagonia’s work on SOCOM’s Protective Combat Uniform program, their military team kept looking at the brand’s commercial garments and fabrics. They spoke of developing “Son of Mars” and finally, about three years ago, they decided the time was right to develop a completely new environmental clothing system, starting completely from scratch.

A couple of factors drove this decision. First, PCU was only making small, evolutionary material and design improvements and second was their mission to innovate. Patagonia is in the business of delivering the best technical outerwear for the most extreme environments and athletes. Guess who operates in the world’s most extreme environments and faces arduous conditions on a daily basis? The SOF Warrior.

They developed a plan: improve performance over the PCU baseline, keep the line tight, and figure out how to reduce risk in production.

According to Eric Neuron, Director of Strategic Product & Military for Patagonia Works, one of the most common critiques of both MARS and PCU is that there are too many garments in the system. MARS Designer Casey Shaw went one step further. He asked himself as he began work on the project, “How do you make one item do the work of six?” One way is materials. The other is design.

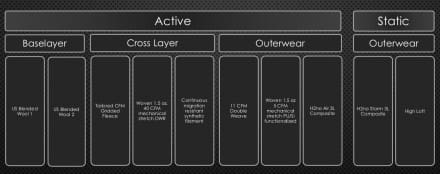

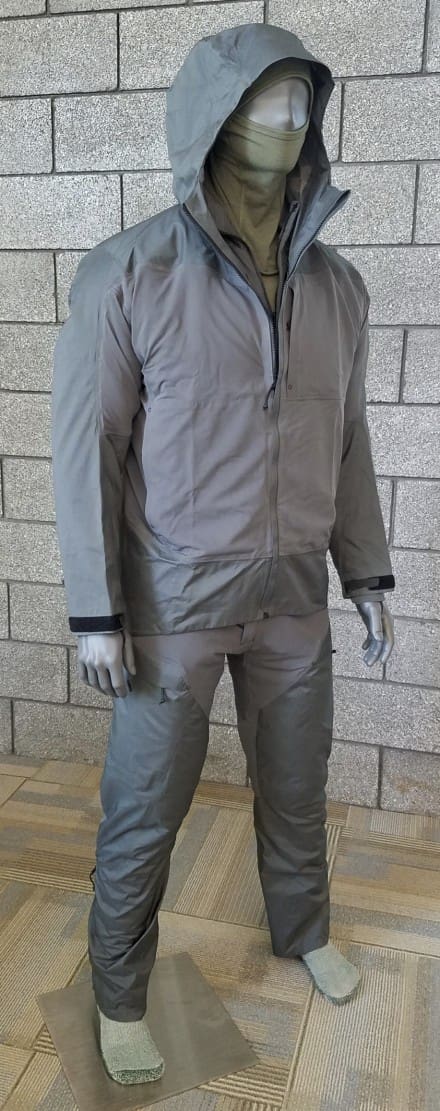

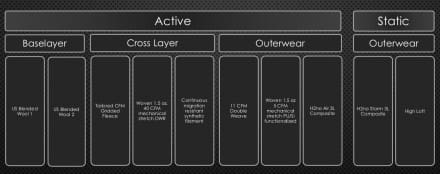

Shaw told me that the new Military Alpine Recce System is designed for long duration missions in mountainous environments, but the user won’t wear any more than three layers at a time to get the desired effect. Along with that, it’s important to understand that this is an active insulation system rather than passive. This means that the wearer takes a more active role in pushing moisture out of the clothing. The trick is to manage air permeability. Essentially, the fabrics are treated in different ways to affect how they breath.

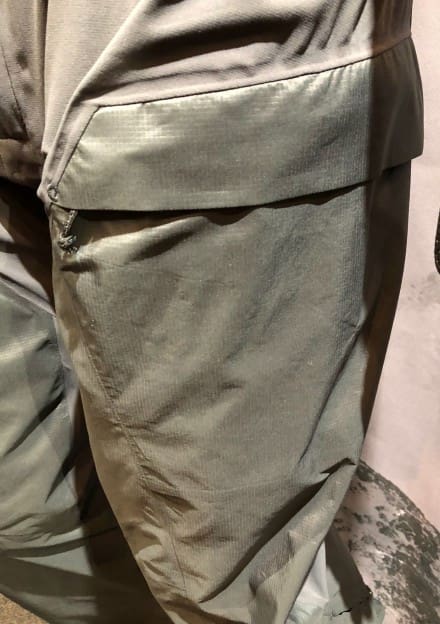

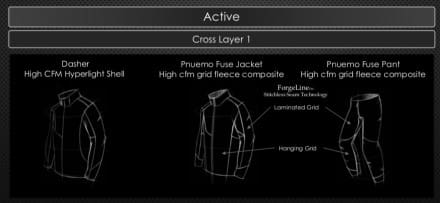

The garments range from .5 – 40 CFM. CFM is a measurement of cubic feet per minute to denote air permeability. To put those numbers into perspective, the Army Combat Uniform is made from a 50/50 Nylon/Cotton blend which is 8 CFM. It’s actually not very breathable at all. For MARS the lower CFM is a waterproof breathable suit, while the higher air perm is a 1.5 oz mechanical stretch knit with Durable Water Repellant treatment. The latter cross layer material offers the “put it on, leave it on” approach which can be used across a wide range of conditions, alone or in concert with other garments.

The team also put some thought into the colors. They are offering two which come from their commercial offerings: Fatigue Green and Forge Grey, which is a dark hue. Neuron explained these will satisfy many organizations’ requirement for civilian clothing for low viz operations. Additionally, he added that they’ll offer MultiCam as well, as it is the SOCOM Standard.

Starting three years ago, the design concept was launched, and the material developments kicked off with Patagonia’s Materials Innovation Group, a team of chemists and textile PhD’s. Then by providence, about 18 months ago, a SOF customer identified a requirement for a new environmental clothing system. MARS got a kickstart and they quickly produced the requisite number of full kits for the source selection. It went up against the best in the business, but won the solicitation and publicly unveiled MARS during last year’s SOF Select event. Since then, they’ve formalized The Lost Arrow Project to manage the program and worked to bring it into production in order to meet their customer’s deadlines.

Capitalizing on this success, they’ve decided to offer MARS to government customers as well as distributors who service the tactical market.

The System

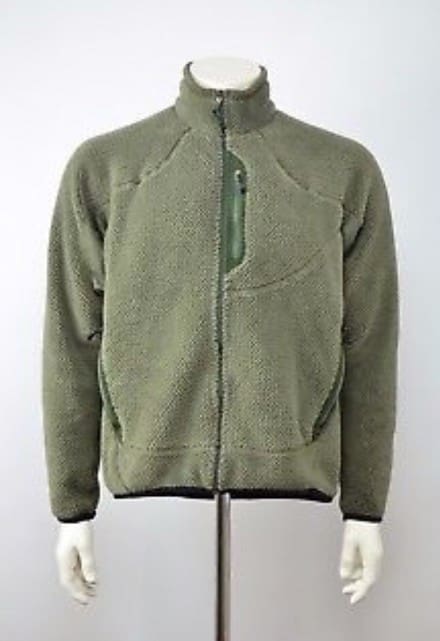

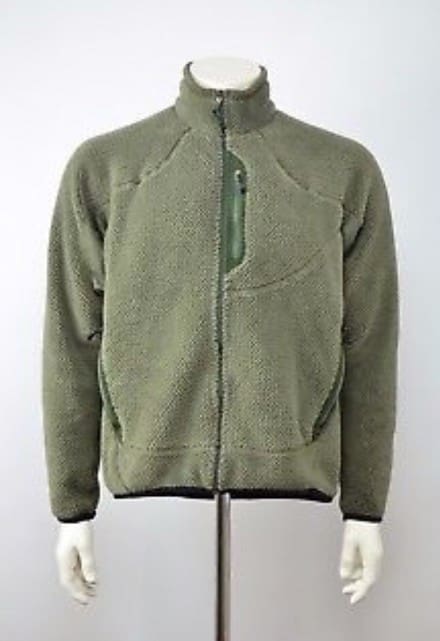

There are a few similarities between the original system and the new one. For instance, some of the components have the same name as the original items. That’s because over the years they’ve been updated with new materials and still suit the overall purpose of the clothing system.

The garments range from FR Wool next-to-skin items, windshirts, insulating vest and jackets to waterproof breathable, fully seam taped overgarments. While it was developed as a full system, they don’t consider MARS an all or nothing proposal. They fully expect and encourage users to purchase and use the components best suited to their needs.

Look at it like a takeout menu. You can order the full system or just pick out what fits. Later, you can add on.

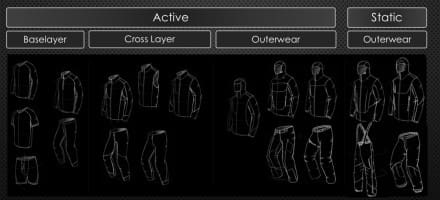

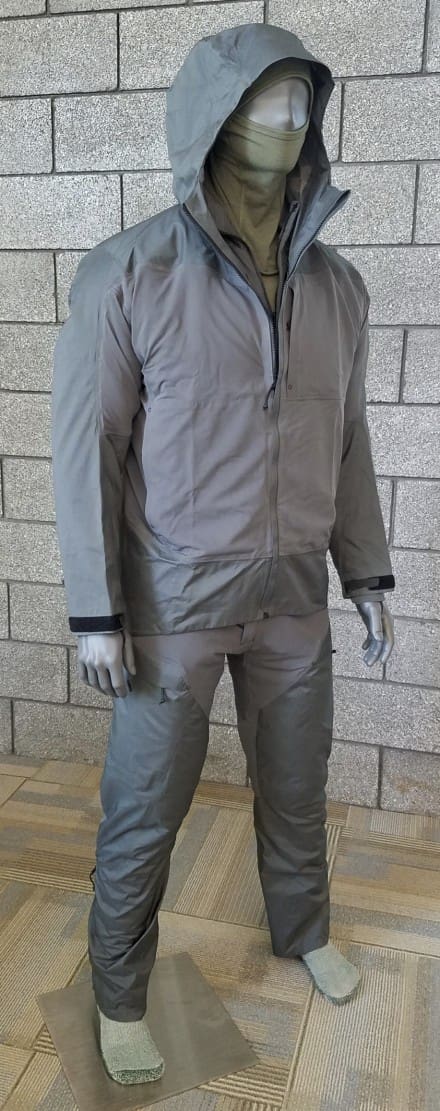

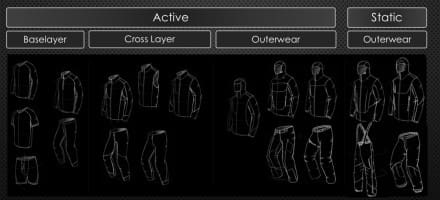

The system consists of 20 separate pieces (including balaclava) and features garments for static operations along with the active focused clothing.

MARS Components

Base Layer 1 – Blended US Wool

Base Layer 2 – Blended US Wool

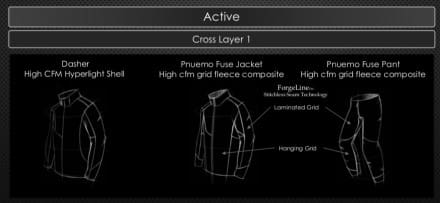

Cross Layer 1 – Woven Air Perm Materials

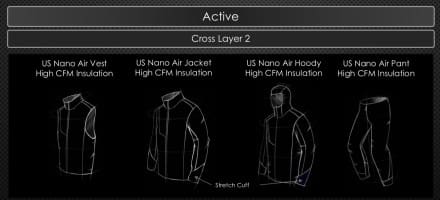

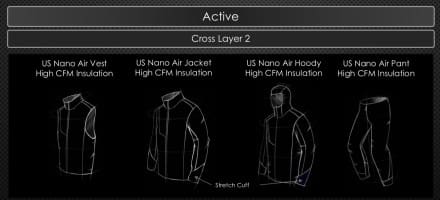

Cross Layer 2 – Woven Air Perm Materials

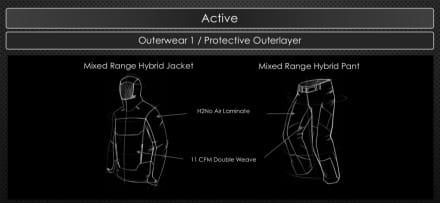

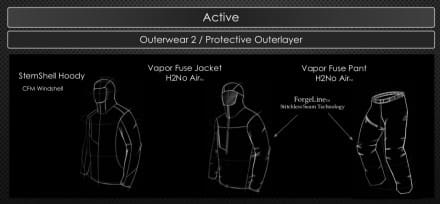

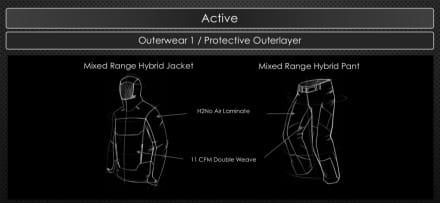

Outerwear 1 – Air Perm Softshell Laminate and Double Weave

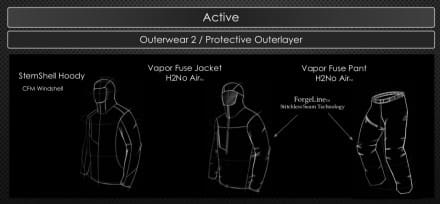

Outerwear 2 – Air Perm Wind Shell and Rain Suit

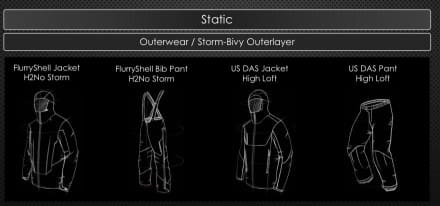

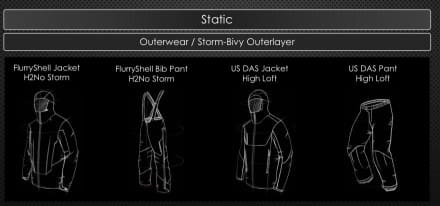

Outerwear Static – High Loft Insulation and Hardshell

How It Works

PCU is a seven level system. It’s based on a mountaineering clothing system described by Mark Twight in his book “Extreme Alpinism: Climbing Light, Fast and High.” SOCOM has been using it for a little over 15 years. Even the US Army’s Extreme Cold Weather Clothing System Gen III is a simplified version of PCU. By this point, most users understand the concept of levels rather than layers and can combine different garments based on activity and environmental conditions.

Eric Neuron explained, “Layering works for surviving the elements, and it’s easy to teach and understand, but it’s not conducive for maximizing your working capability. MARS works just fine as a traditional layering system, but the vision was to create a toolbox of kit, that if you know your own bio-output and the task at hand, you only to need pull out the appropriate tools. The guys instinctively know this already, and the world’s top alpinist approach clothing this way, our task is simply to make the best tools.”

MARS is a completely fresh look at the challenge. Everyone will have to familiarize themselves with new garments and how to use them, alone, or in concert with one another. Then they’ll have to figure out which they’ll need to use in different scenarios. I’ve spoke with both Neuron and Shaw about this and they are looking at ways to help the user. One concept is an app which helps the user select the right pieces. Another, which was used with PCU, is offering instruction by SMEs.

Saving Time and Money

There’s a business case to be made for both client and vendor every time a new piece of equipment is purchased by the government. The cost of the system is the sum of all of the different elements from the supply chain as well as assembly of the materials into finished goods. As you’ll see, time is also a factor which must be considered. Some materials take longer than others to source.

Generally, an environmental clothing system relies upon multiple different materials which are combined to garner different effects. Each of those materials has its own part of the supply chain. The vendors who make those raw goods each have minimum order quantities (MOQ). Let’s say a system has five different materials. That’s five different MOQs which must be ordered. Each with their own lead times. Those all have to be synchronized so that they are ready for assembly at the same time. It gets even more complicated when clients want it in multiple paint jobs.

Some wonder why companies don’t want to have clothing systems, or other gear for that matter, sitting on the shelf. That’s because once those materials are assembled into a finished good, it costs money to carry on the shelf, hoping someone will buy it. Imagine a company builds a run of clothing and they manufacture a wide range of sizes. Some of those low demand sizes like extra long and extra short versions, may never be purchased. The capital wrapped up in finished goods isn’t recouped until they are sold and could be used elsewhere in a business such as paying for more raw goods to fulfill other orders.

One of the ways Patagonia has been able to lower their MOQs is by utilizing a common face fabric for most of these garments. That means the raw goods offer more versatility because they can be made into many different garments. Patagonia tweaks the fabric’s performance by applying treatments or laminating it to other materials, resulting in a highly efficient material usage across the system.

With MARS, Patagonia takes a stocking position for raw goods which cuts down on lead times for materials from mills and gives them the flexibility to produce what the customer wants. Granted, it’s not as fast as buying something off the shelf, but it also cuts out the wait for the supply chain to mill fabrics and treat them. Hopefully, it will be a happy medium. Of course, it relies on efficient customer forecasts.

“We believe that for a government contracting business, utilizing a build-to-order uniform business model that allows quick turns and low MOQ will ultimately provide the best value to the customer,” said Neuron, adding, “US manufacturing is expensive, we have worked hard to address that in the business strategy, and with an eye towards automation solutions to produce exceedingly technical domestic products. I believe this is the key to bolster the US clothing manufacturing base.”

One way to fulfill “we’re leaving tomorrow” requests is to work with distributors willing to take a stocking position on individual components of MARS or entire kits, based on their knowledge of their clients.

But going back to the idea of encouraging customers to buy what they need, minimums have dropped drastically. For instance, what once required a minimum order of 1000 kits has dropped to 200.

Additionally, MARS is completely Berry compliant. They selected materials which could be produced here in the US, yet still provide all of the performance they were looking for. They even went as far as designing a new buckle for the hood of the jacket.

These are technical garments using advanced materials and construction techniques. The most critical factor in the success of a revitalized MARS line is domestic production. Consequently, Patagonia has not only prepared a supply chain for the materials needed but also invested in their production partner, Peckham Vocational Industries. In doing so, they’ve installed machinery capable of modern construction techniques like sonic welding, as well as provided instruction on how to use them. Patagonia Subject Matter Experts have been on hand at Peckham, showing lead sewers tricks of the trade. This investment is going to allow the military to adopt more modern clothing designs and keeps Peckham competitive, even with overseas factories, which generally benefit from regular infusions of new machinery.

When I spoke with Eric Neuron about it, he said, “We are fortunate to be able to cut through the noise, and focus only on the goal of solving problems and bringing innovation to the guys. In this case, that means investment of time, money and knowledge transfer to the US supply chain. And we have the best US partners in place to deliver on that goal.”

Both Patagonia and Peckham have assumed some risk here. So far, they’ve got one customer, but by expanding the program they’ve taken the “build it and they will come” approach. There’s nothing like MARS currently in the market. While there are a lot of great individual pieces, from a variety of manufacturers, no one has taken such a bold move to introduce such an ambitious line all at once in quite some time. Even then, there were significant preorders. They’ll have to educate customers on the system, how to use it and how to purchase it.

This is the second of a four-part series on the Military Alpine Recce System developed by Patagonia’s The Lost Arrow Project. Other installments include an the history of Patagonia’s SOF support, a focus on their production partner Peckham Vocational Industries and a deep dive into some of the components. The full system will be on exhibit at SOF Select during SOFIC.