This is the latest info shared with industry during a recent briefing. Everything is subject to change but most of it jives with what I have heard elsewhere.

-The Army selected a new camouflage pattern o/a 5 May 2014 as previously reported here on SSD.

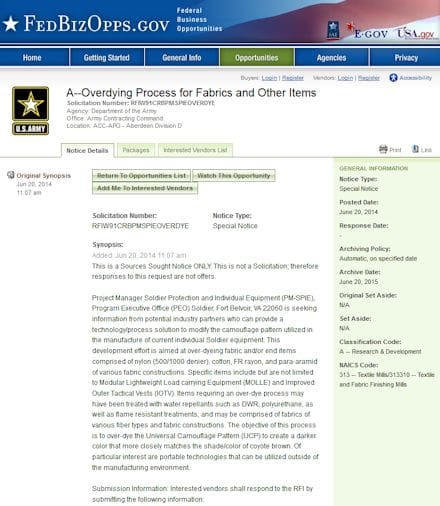

-There is still no formal announcement from Army leadership but PEO Soldier and Natick are working very closely with industry to make this happen.

-Official, Berry Compliant, Scorpion W2 fabric is being printed. It is Scorpion W2 and not the W1 variant that everyone keeps searching for on the internet. I do not have photos of the pattern yet but a friend has seen it at the printers and describes it as similar to MultiCam but with very distinct differences. Attention Chinese printers attempting to flood the market with knockoff Scorpion fabric; you’re printing the wrong pattern!

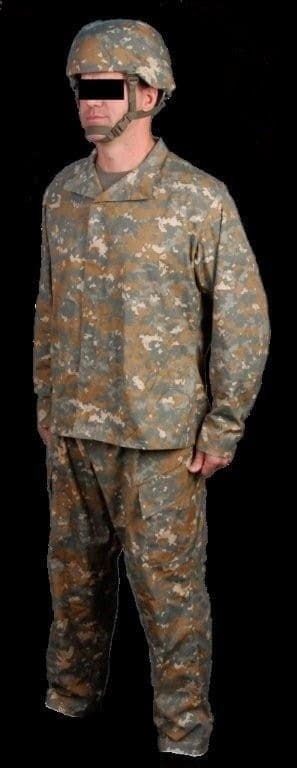

-The ACU will continue to be the style of uniform. It will just have a new paint job but also incorporate modified sleeve pockets with zippers from the Army Combat Shirt. No other changes have been announced.

-Boots and gloves will be solid Coyote 498. No definitive word yet on t-shirts.

-Pulls such as loop and hook, thread, zippers and so on, will be Tan 499 as is currently used with MultiCam OCP. I still have no word on Scorpion printed webbing or hook and loop.

UPDATE

These are Tan 499 (left) and Coyote (right) color chips from ITW which we first shared in 2010 when the Army had just adopted OCP and wanted to let you know what was going on.

-Currently, a tentative mandatory possession date for Scorpion clothing bag items is 3 years from the decision date. However, mandatory wearout/possession dates traditionally have fallen on Sep 30/Oct 1 to coincide with the fiscal year. No word yet on the wearout date for UCP or MultiCam/OCP. Despite assertions to the contrary by some, DLA continues to purchase items in MultiCam/OCP and the Army is fully aware that OCIE items in a modified UCP (Coyote overdye) as well as the MultiCam variant of OCP will remain in service for years to come.

-The goal is for clothing bag items in the new Scorpion W2 pattern to be available in 128 military clothing stores by May 1, 2015 and in clothing bag issues to new accessions starting Oct 1, 2015 at the 4 major Basic Training Central Issue Facilities. This is different than previous transitions to new patterns which saw issue to new accessions and their Drill Sergeants first with slightly delayed availability to the rest of the force.

-The Army is working closely with DLA Troop Support to only procure fill in sizes of ACUs in UCP. They have to continue to purchase them so long as they continue to issue them to new accessions in the clothing bag. This is one reason that making Scorpion W2 available first to the existing force through the Clothing Sales Stores makes little sense. The sooner they transition Basic Trainees to Scorpion, the sooner they can stop purchasing UCP. This plan would waste taxpayer dollars by purchasing unneeded uniforms that do not perform.

-The Army anticipates that at least 1/2 of its Soldiers will possess Scorpion ACUs within the first year. They are also anticipating a run on the clothing sales stores and are working hard to create a sufficient stock.

-Planners have prioritized clothing and equipment into 4 tiers. Tier 1 is everything that goes into the clothing bag and these are the main priority as the Army wants these available at Clothing Sales by May 1, 2015. Tier 2 includes all combat clothing items that have been purchased through RFI. Tier 3 and 4 products such as sleeping bags are considered less critical items.

-A large amount of money is planned for the transition (I am told up to $370 million) starting 1Q FY 2015. The Army plans to acquire Scorpion print equipment in one of two ways. First, they plan to modify current DLA Troop Support contracts that have approximately 2 or more option years remaining. On other items, Natick will issue new contracts, especially for those items that have traditional long lead times through DLA Troop Support.

-The primary means of transitioning from MultiCam OCP to Scorpion for TA50 will be through RFI/Deployer Equipment Bundles. MultiCam and UCP kit will remain in some parts of the force for some time to come. Yes, expect some mixing of patterns with OCIE for the near term. It’s going to happen. Hopefully, it won’t be uniform coats and trousers.

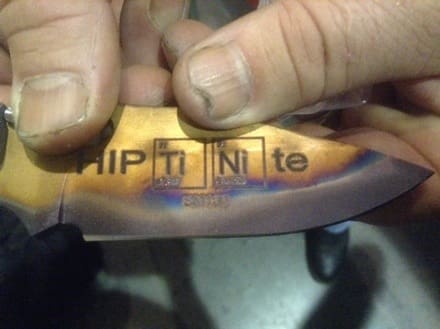

-The Army has currently contracted 5 printers with each concentrating on a different type of material such as NYCO, Cordura, FR, etc. Already, 1,500 to 2,000 yards of NYCO and Cordura have been printed. That is but a drop in the bucket. The long pole in this tent is getting the materials to pass the shading process and then to get different printers to learn how to do more than one substrate (type of material). Each type of material or substrate absorbs dye differently and the adoption of multiple patterns by DoD over the past 10 years has taught us that this process isn’t easy for companies to perfect. Specialists at Natick must examine fabric samples from each run and ensure that they meet quality standards for color and print. The Army desires to add additional printers but the bench is only so deep and the their missteps regarding a camouflage path forward and subsequent curtailing of purchases of combat clothing and equipment have sent the supply chain into disarray. Several years ago, shading process issues with USAF Digital Tigerstripe almost ran one company out of business. Some companies may not recover.

-There is no word on whether Scorpion W2 will be an unrestricted pattern meaning it could be printed and sold commercially. Based on some legal issues, Scorpion W2 may well not be available for use by manufacturers for commercial use or for outside of program buys. If it is not, no commercial products in Scorpion W2 will be available. The Army will have to decide whether it will allow Soldiers to use commercial products such as day packs in MultiCam. The patterns are similar in nature and use similar colors but they are not exact.

-Air Force deployers: You get your clothing and equipment from the Army’s stocks. You’ll get what the Army is issuing, when it issues it. This may be MultiCam OCP or Scorpion OCP.