RESEARCH TRIANGLE PARK, N.C. — New Army research provides a better understanding of the swelling that occurs in the brain during a stroke, which could contribute to new treatment strategies for stroke patients and have potential implications for traumatic brain injuries.

Cerebral edema, swelling that occurs in the brain, is a severe and potentially fatal complication for stroke victims. Research, funded in part by the Army Research Office and conducted at The University of Rochester Medical Center, shows for the first time that the glymphatic system — normally associated with the beneficial task of waste removal — goes awry during a stroke and floods the brain, promoting edema and drowning brain cells.

The research, conducted with mice, appears in the journal Science.

“These findings show that the glymphatic system plays a central role in driving the acute tissue swelling in the brain after a stroke”, said Maiken Nedergaard, M.D., D.M.Sc., co-director of the University of Rochester Medical Center Center for Translational Neuromedicine and senior author of the article. “Understanding this dynamic — which is propelled by storms of electrical activity in the brain — point the way to potential new strategies that could improve stroke outcomes.”

The glymphatic system, first discovered by the Nedergaard lab in 2012, consists of a network that piggybacks on the brain’s blood circulation system and is comprised of layers of plumbing, with the inner blood vessel encased by a ‘tube’ that transports cerebrospinal fluid. The system pumps the fluid through brain tissue primarily during sleep, washing away toxic proteins and other waste.

Before the findings of the new study, scientists assumed that the source of brain swelling was exclusively the result of fluid from blood.

“Our hope is that this new finding will lead to novel interventions to reduce the severity of ischemic events, as well as other brain injuries to which Soldiers may be exposed,” said Matthew Munson, Ph.D., program manager, fluid dynamics, ARO, an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory. “What’s equally exciting is that this new finding was not part of the original research proposal. That is the power of basic science research and working across disciplines. Scientists ‘follow their nose’ where the data and their hypotheses lead them — often to important unanticipated applications.”

AN ELECTRICAL WAVE, THEN THE FLOOD

Ischemic stroke, the most common form of stroke, occurs when a vessel in the brain is blocked. This blockage denies the nutrients and oxygen cells need to function, which results in their rapid depolarization. As the cells release energy and fire, they trigger neighboring cells, creating a domino effect that results in an electrical wave that expands outward from the site of the stroke, called spreading depolarization.

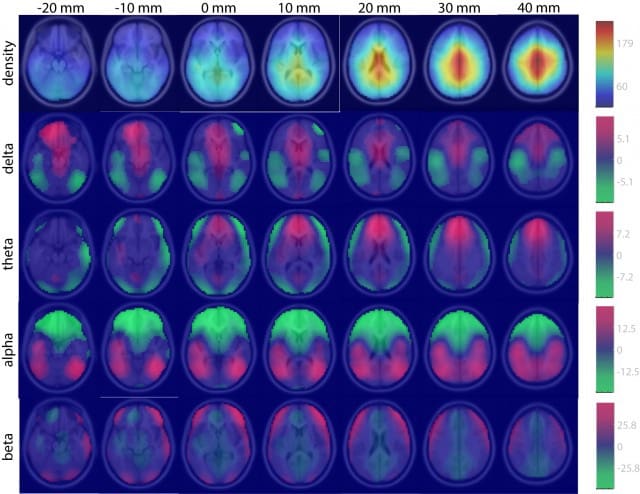

During the spreading depolarization, vast amounts of potassium and neurotransmitters released by neurons into the brain cause the smooth muscle cells that line the walls of blood vessels to seize up and contract, cutting off blood flow in a process known as spreading ischemia. Cerebrospinal Fluid then flows into the ensuing vacuum, inundating brain tissue and causing edema. The already vulnerable brain cells in the path of the flood essentially drown in fluid and the brain begins to swell. These depolarization waves can continue in the brain for days and even weeks after the stroke, compounding the damage.

“When you force every single cell, which is essentially a battery, to release its charge it represents the single largest disruption of brain function you can achieve — you basically discharge the entire brain surface in one fell swoop,” said Humberto Mestre, M.D., a Ph.D. student in the Nedergaard lab and lead author of the study. “The double hit of the spreading depolarization and the ischemia makes the blood vessels cramp, resulting in a level of constriction that is completely abnormal and creating conditions for CSF to rapidly flow into the brain.”

The study correlated the brain regions in mice vulnerable to the fluid propelled by the glymphatic system with edema found in the brains of humans who had sustained an ischemic stroke.

POINTING THE WAY TO NEW STROKE THERAPIES

The findings suggest potential new treatment strategies that, used in combination with existing therapies, focus on restoring blood flow to the brain quickly after a stroke. The study could also have implications for brain swelling observed in other conditions such as subarachnoid hemorrhage and traumatic brain injury.

Approaches that block specific receptors on nerve cells could inhibit or slow the cycle of spreading depolarization. Additionally, a water channel called aquaporin-4 on astrocytes — an important support cell in the brain — regulates the flow of the fluid. When the research team conducted the stroke experiments in mice genetically modified to lack aquaporin-4, the fluid flow into the brain slowed significantly.

Aquaporin-4 inhibitors currently under development as a potential treatment for cardiac arrest and other diseases could eventually be candidates to treat stroke.

In additional to the Army Research Office, the research was supported with funding from National Institute of Neurological Disorders and Stroke, the National Institute of Aging, Fondation Leducq Transatlantic Networks of Excellence Program, the Novo Nordisk and Lundbeck Foundations, and E.U. Horizon 2020.

By U.S. Army CCDC Army Research Laboratory Public Affairs