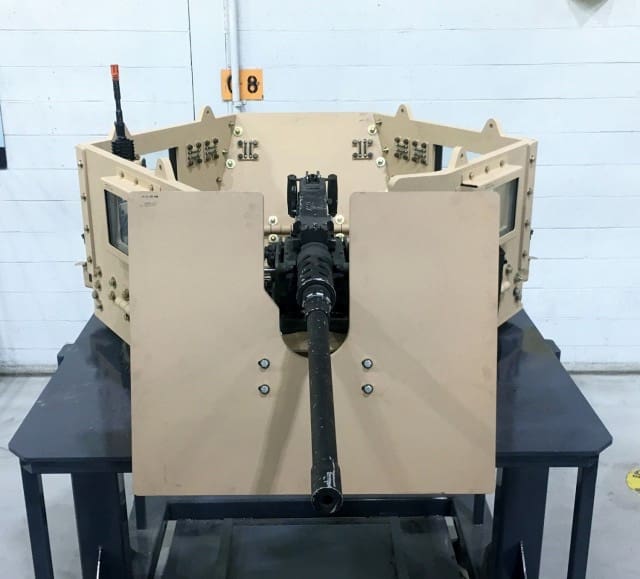

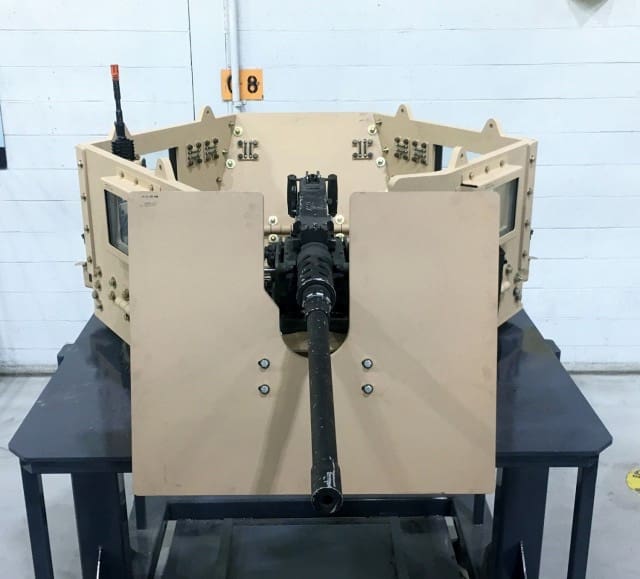

PICATINNY ARSENAL, N.J. — Engineers at Picatinny Arsenal have developed a unique gunner protection turret, quickly foldable to a reduced height, which will make it easier for the U.S. Marine Corps to transport the turret in a number of scenarios.

The versatility and compactness of the turret evokes comparisons to the “Transformer” science fiction movies, which feature robots that can transform themselves into common machinery, such as vehicles.

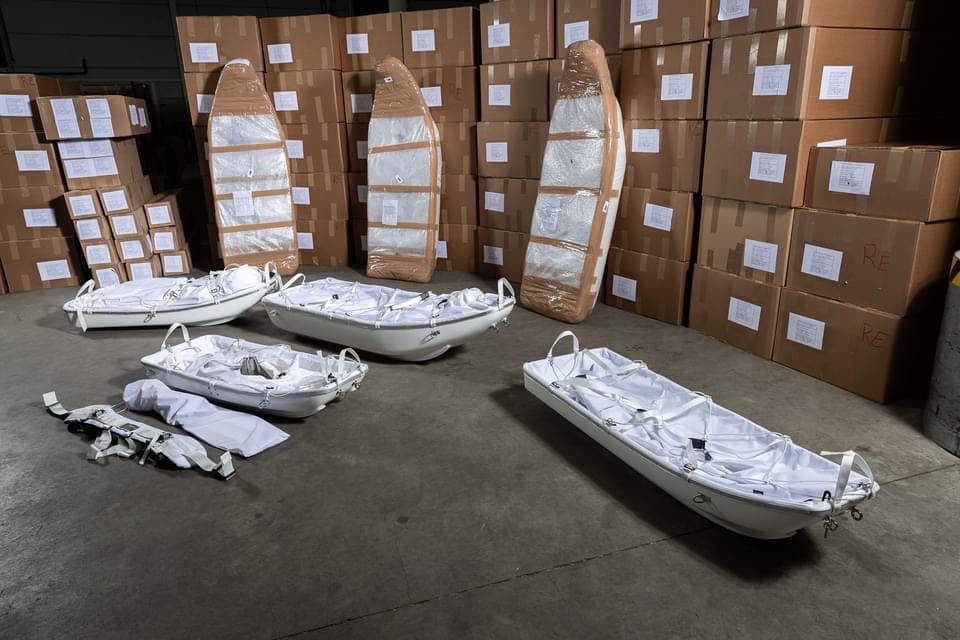

In its reduced configuration, the new turret allows for more efficient transportation aboard naval vessels, aircraft and ground transport systems. Designated as the Reducible Height Gunner Protection Kit (RHGPK), the turret can quickly fold to nearly one-third of its original height, thus allowing for adequate clearance within tight transportation decks.

Moreover, the reducibility feature is ideal for limited deck spaces aboard Naval amphibious transport dock ships and Maritime Prepositioned Force ships without the need to remove the RHGPK from the host vehicle. The new turret is undergoing test and evaluation with the Marine Corps System Command on the Joint Light Tactical Vehicle (JLTV) Heavy Guns Carrier (HGC) variant.

“The RHGPK essentially is an armored Transformer,” said Thomas Kiel, who leads the engineering design of gunner protection kit (GPK) turrets within the U.S. Army Combat Capabilities Development Command Armaments Center, located at Picatinny Arsenal.

“The turret is unrecognizable once it’s reduced for transportation purposes,” Kiel added. Marine Corps expeditionary operations use fully amphibious platforms, such as the Landing Craft, Air Cushion (LCAC) to transport weapons systems, equipment, and personnel within assault elements from ship to shore and across the beach.

The RHGPK turret will be mounted on tactical vehicles being transported on amphibious ships entering hostile regions. “Marines need to be able to focus on the mission during a beach landing, and not be concerned with how to prepare a turret for the operation,” said Kiel. “The RHGPK has been engineered to allow Marines to raise the turret and mount the weapon in a matter of minutes, while on a moving landing craft.”

The turret is the latest addition to the portfolio of Objective Gunner Protection Kit (OGPK) family of protective armor kits for tactical vehicle turret gunners.

GPK turrets are protective structures that mount to a rotating bearing ring on the roofs of tactical wheeled vehicles. A turret typically is considered to be defensive weapon system due to its inherent opaque and transparent armor, which is configured to maximize the protective area surrounding the gunner. In addition to enhancing survivability, the turret is the primary weapon station for the vehicle platform, enabling the gunner to deliver firepower on targets.

“The voice of the warfighter is critically important when developing a new weapon system,” Kiel said. “Restrictions during the pandemic forced us to conduct our initial user evaluations with virtual models instead of physical prototypes.”

Also located at the Armaments Center, the Gaming, Interactive Technologies & Multimedia team worked closely with the GPK engineers to generate fully immersive, virtual reality scenarios. That made it possible to evaluate the overall effectiveness of the design, from the perspective of space requirements, protection, situational awareness and weapon functionality.

The RHGPK enables the Joint Light Tactical Vehicles, Medium/Heavy Tactical Vehicle Replacement and Logistics Vehicle System Replacement, to be transported in the lower vehicle stowage areas of Landing Platform/Dock (LPD 17) and Landing Helicopter Dock class ships. The turret’s reducible feature will also facilitate transportation by rail and air.

“The backbone of our design is the solid model,” said Kris Mayer, turret design engineer at the Armaments Center’s Prototype Integration Facility. “It is the source for manufacturing data and many other engineering functions,” he added. The solid model feeds all aspects of the design life cycle, including cost estimating, structural analysis, weight predictions, platform integration and weapons interfacing.

“When things are done properly, the fabricated hardware will look exactly like the computer model with no surprises,” said Mayer. Proper configuration management allows future design updates to be incorporated seamlessly.

Project Manager Soldier Lethality, located at Picatinny Arsenal, has primary responsibility for Gunner Protection Kit turret development under the Gunner Integrated Protection and Restraint System program. It also manages the procurement of turret systems within the Department of Defense.

“There are a wide variety of tactical vehicle platforms within the DoD,” explained Narayan Bhagavatula, Program Lead for Gunner Protection Systems. “Many of these require unique turret solutions because of specific user requirements and weapons that must be mounted,” he added. The GPK turret designs are generated in-house at the Armaments Center by Army civilian engineers.

Each turret within the portfolio of OGPKs has its own specific configuration. However many components are shared among the various designs. This results in more affordable products and a smaller logistics footprint for sustainment. Also, because the designs are owned by the U.S. government, competitive production contracts can be sourced among small and large businesses throughout the United States.

Picatinny Arsenal, located in northern New Jersey, provides a wide variety of guns, ammunition, products and related services to all branches of the U.S. military. The Armaments Center is part of the U.S. Army Combat Capabilities Development Command, or DEVCOM, which is under the Army Futures Command.

By Ed Lopez, Picatinny Arsenal Public Affairs