Galvion, a global leader in the design and manufacture of innovative head systems, power and data management solutions, and integrated soldier systems, has expanded its Charge on the Move capability with the introduction of new vehicle-mounted and dismounted integration accessories designed to support real-world operational use. This announcement coincides with SHOT Show, taking place in Las Vegas, 20-23 January 2026, where Galvion is exhibiting the Charge on the Move system alongside their wider product offering on booth #32003.

Building on the field-proven Squad Power Manager™ (SPM), these new accessories transition Charge on the Move from a demonstrated capability into a scalable, mission-ready solution that enables power generation, distribution, and battery charging while on the move—whether mounted in vehicles or carried by dismounted operators. The expanded offering includes a vehicle mounting solution for the SPM, developed in collaboration with Juggernaut.Case™, and a Mobile Power Pack, created with Haley Strategic™, providing a fully integrated, modular option for dismounted power and radio management.

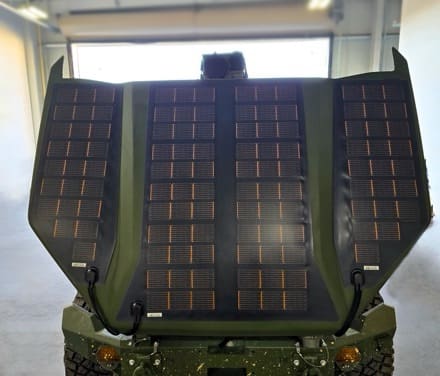

The SPM Vehicle Mount securely installs the Squad Power Manager across a wide range of vehicle platforms, supporting rapid installation, clean cable routing, vibration protection, and tool-free removal for dismounted operations. Designed to accommodate varied vehicle interiors and mission needs, the mount offers multiple attachment options, allowing units to position the SPM where it is most accessible. Tested to relevant MIL-STD environmental requirements, the mount supports reliable power access while vehicles are in motion, allowing soldiers to arrive at the point of dismount with charged batteries and powered equipment.

Complementing the vehicle configuration, the Mobile Power Pack offers a complete, ready-to- deploy backpack-based solution designed to carry the SPM, SoloPack™ batteries, radios, cabling, and associated accessories in a single optimized loadout. Developed with Haley Strategic, the pack integrates modular organization panels, cable routing, and ergonomic load distribution to support communications-heavy roles and extended operations

Todd Stirtzinger, CEO at Galvion, said: “Charge on the Move was always envisioned as more than a single configuration—it’s about giving units flexible options to manage power across platforms and phases of a mission. These integrations reflect how operators actually work, and how partners can help accelerate deployable capability rather than one-off prototypes.” He added: “By working with established industry partners, Galvion continues to expand our power and data ecosystem beyond standalone hardware, offering validated configurations that can be adopted as accessories or tailored into program-specific kits.”

The Charge on the Move vehicle mount and mobile pack are available as accessories for existing Squad Power Manager systems and can be incorporated into customized power and communications kits based on mission and user requirements.