WASHINGTON D.C. — AgEagle Aerial Systems Inc. (dba, EagleNXT) (the “Company” or “EagleNXT”) (NYSE: UAVS), a leading provider of advanced drone and aerial imaging solutions, is proud to announce an expanded strategic partnership with Tough Stump Technologies, a premier innovator in advanced training solutions for defense and security applications. As part of the partnership, the two companies are announcing the new HELIOS™ kit, a next-generation, rapidly deployable platform that will include the eBee VISION drone from EagleNXT. This cutting-edge solution is available now, and will advance Intelligence, Surveillance and Reconnaissance (ISR) to a higher level of performance.

The HELIOS™ system is designed to be a rapidly deployable, open-architecture platform providing real-time, actionable intelligence. Building on the proven ARTEMIS™ package,HELIOS™ incorporates the advanced eBee VISION drone, the ATOS tracking system, and a robust portable processing unit. This combination delivers unparalleled situational awareness and data synthesis, engineered for seamless interoperability with the Next Generation Command and Control (NGC2) prototype ecosystem. HELIOS™ is a cost-effective, low-bandwidth solution that will empower users to modernize their command-and-control systems and gain a decisive advantage in dynamic operational environments.

“We are proud to work with Tough Stump Technologies to expand our collaboration and as a first product of that, bringing the game-changing HELIOS™ system to the marketplace,” said Bill Irby, CEO and President of EagleNXT. “This partnership reflects our shared commitment to delivering innovative, defense-focused solutions that enhance mission success and operational readiness. The HELIOS™ package is the result of our ongoing collaboration and represents another advanced offering that will deliver real-time intelligence and interoperability. We’re excited to see it match the evolving demand for unmanned capability.”

Also announced at AUSA, EagleNXT and Tough Stump Technologies are expanding their strategic partnership to also include cooperative marketing and promotional opportunities and closer alignment in pursuit of U.S. government business.

“Tough Stump is thrilled to deepen our alliance with EagleNXT, a true partner in innovation,” Jarrett Heavenston, CEO of Tough Stump Technologies. “Together we are addressing the unmanned needs with the Department of Defense and will expertly deliver the technologies that deliver capability and enhance what we offer to our U.S. Government and Federal customers and clients. With the new HELIOS™ package, along with our planned co-marketing efforts and joint pursuit of USG opportunities, we will unlock unprecedented value for customers, ensuring they have access to the most advanced, interoperable solutions available.”

For more information on the HELIOS™ package, visit Toughstump.com.

For more information about the full suite of EagleNXT UAS solutions, or to schedule a demo, visit EagleNXT.com or contact the AgEagle Media Relations team.

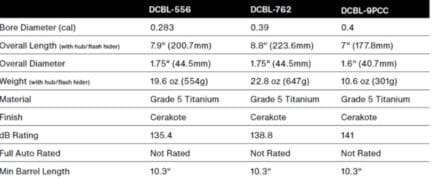

Plymouth, MI (November 2025) – EOTECH is diversifying its portfolio with the introduction of the DCBL line of firearm suppressors. The DCBL suppressor series embodies the pinnacle of modern suppressor design, integrating advanced materials, user-centric features, and a perfect balance of weight and suppression. The 3D-printed, Grade 5 Titanium, flow-through design, makes it a cleaner shot process with reduced recoil.

Plymouth, MI (November 2025) – EOTECH is diversifying its portfolio with the introduction of the DCBL line of firearm suppressors. The DCBL suppressor series embodies the pinnacle of modern suppressor design, integrating advanced materials, user-centric features, and a perfect balance of weight and suppression. The 3D-printed, Grade 5 Titanium, flow-through design, makes it a cleaner shot process with reduced recoil.