FORT LEONARD WOOD, Mo., June 10, 2025 — Overland AI’s fully autonomous tactical vehicles, ULTRA, were deployed across 15 live mission scenarios to comprehensively demonstrate end-to-end, Soldier-operated ground autonomy.

ULTRA, Overland’s fully autonomous tactical vehicle, operating in dense forest and utilizing tree line for cover during mission scenarios at Fort Leonard Wood, Mo.

Soldiers from the 555th, 36th, and 20th Engineer Brigades, and the 173rd Airborne Brigade, executed these 15 missions using two ULTRAs. They also leveraged Overland’s tactical C2 interface, OverWatch, to plan, execute, and adapt operations on the fly. From pre-operation vehicle checks, payload swaps and munition loading, to mission planning and execution in OverWatch, the experimentation event was conducted almost entirely by end users.

“This was a particularly unique event,” said Chris Merz, who serves as the director of product at Overland AI. “Nearly every phase of the operation—from munition loading to software-based replanning—was in the hands of the Soldier. We saw real independence from the operator, not just in planning and execution, but in adapting tactics in real time.”

ULTRA deploying smoke deception to confuse the enemy and create an element of surprise during a day mission in wooded terrain.

Participating units were tasked with planning complex, multi-vehicle missions. Soldiers used ULTRA’s modular platform for kinetic and electronic warfare breaching, terrain shaping with XM204s, deception, obscuration, and delivery of third-party payloads, including uncrewed aerial vehicles (UAV) and electronic warfare (EW) capabilities.

Overland’s autonomy stack is highly adaptable in the field. Some operators re-tasked vehicles mid-mission in response to enemy activity and adjusted payload configurations under time pressure with little notice. Other operators, planning two simultaneous terrain-shaping missions with over 20 checkpoints and five tasks per vehicle, took less than three minutes to plan.

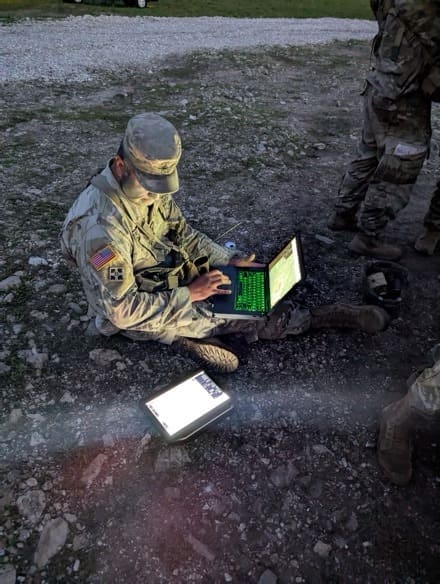

A Soldier from the 555th Engineer Brigade plans a series of missions with ULTRAs using OverWatch, Overland’s intuitive, tactical command and control (C2) interface.

“Our mission is to empower the Armed Forces to dominate any and all missions they need to accomplish,” said Byron Boots, co-founder and chief executive officer of Overland AI. “This wide-ranging event showed that Soldiers both trust our autonomous land systems and can leverage our versatile capability from start to finish.”

Overland AI remains committed to advancing autonomous military technologies, having previously secured an $18.6 million contract with the U.S. Army and the Defense Innovation Unit (DIU) to develop autonomy software for the Army’s Robotic Combat Vehicle (RCV) program. The company continues to support a range of U.S. military programs, including the U.S. Army, Marine Corps, and Special Operations Command.

To learn more about Overland AI and see open roles, visit www.overland.ai.