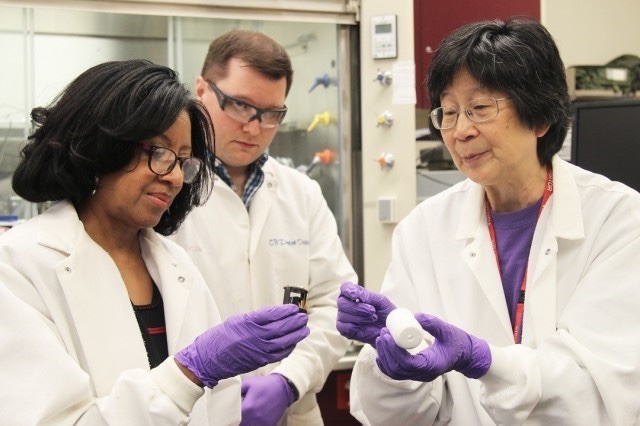

The University of Texas System and the United States Army Futures Command (AFC) have formed an official educational and cooperative research partnership to advance medical science and technology to save lives both on and off the battlefield.

Since last year, leaders from the UT System, AFC, U.S. Army Medical Research Command and U.S. Army Institute of Surgical Research (USAISR) have been exploring how to work together to solve some of the most critical issues affecting soldiers injured in combat.

Today, they formally signed two agreements to streamline collaboration between the military and UT institutions: an Educational Partnership Agreement and a Cooperative Research and Development Agreement.

The agreements will allow a continuous flow of resources, research, and scientific expertise, focusing specifically on medical science and technological innovations.

“I can not emphasize how groundbreaking this will be,” said Lt. Gen. James Richardson, AFC acting commanding general. “This will allow opportunities for furthering research and expand capabilities for improving our work in the critical area of trauma care, which will extend to our future soldiers and also have impacts in our communities.”

The partnership will leverage the scale and expertise of the both the UT System and the Army, UT System Chancellor James B. Milliken said. “The military brings to the table a substantial health research infrastructure, unrivaled experience in battlefield trauma, and the capacity to test innovations in the field,” Milliken said. “UT institutions offer an extensive basic and applied science infrastructure, a world-class system for conducting clinical trials, and some of the world’s most brilliant and innovative minds.”

During a Summit last year, researchers and military health specialists from AFC and the UT System emphasized the need to turn the “Golden Hour” into the “Golden Day,” referring to the timeframe following a battlefield wound when proper medical treatment is crucial to survival. Following the Summit, several UT institutions and USAISR developed collaborating research proposals to address the underlying causes of tissue damage and novel treatment options following trauma.

The UT System and Army Futures Command anticipate that the new partnership will have long-lasting impacts on both soldiers as well as civilians who suffer traumatic injuries that land them in the emergency room. The partnership also builds on numerous existing collaborations between the Army and UT institutions.

The UT System Board of Regents allocated $50 million to UT Austin to establish facilities to develop and test robotic systems and artificial intelligence through the new Robotics Center of Excellence . Researchers at UT Arlington are studying the human dynamics of decision-making, and UT Dallas is creating chemically powered artificial muscles that could power robotic mules to serve as alternative Army vehicles. UT San Antonio and UT El Paso are working with the Army to advance cybersecurity.

In addition, the UT System currently has several research projects with the Department of Defense to create more technologically advanced cybersecurity systems and to support the use of robotics in combat. The collaboration aims to deliver breakthroughs in the science of combat casualty care, such as delivering oxygen to tissue, shock management, wound progression and infection, as well as physical pain or PTSD.