Pinehurst, NC – Military Products, an American Manufacturer of Military Grade Tactical Products under TAC Shield® and supplier of Quality Shooting Gear under SPORT RIDGE®, is pleased to announce our new products categories and exciting new offerings will debut in the Main Hall booth #14427.

“We always enjoy exhibiting at the SHOT Show while getting to see our customers and old friends. With our exciting new products and greatly expanded booth, we expect to have a very productive and rewarding show” says David Nau, Owner.

Tac Shield® will feature its RZR™ MOLLE Line of a lightweight, rugged, streamlined family of Pouches, Plate Carriers, Gun and Rigger belts, plus the new 2n1 Warrior Slings that have Push-button QD® swivels.

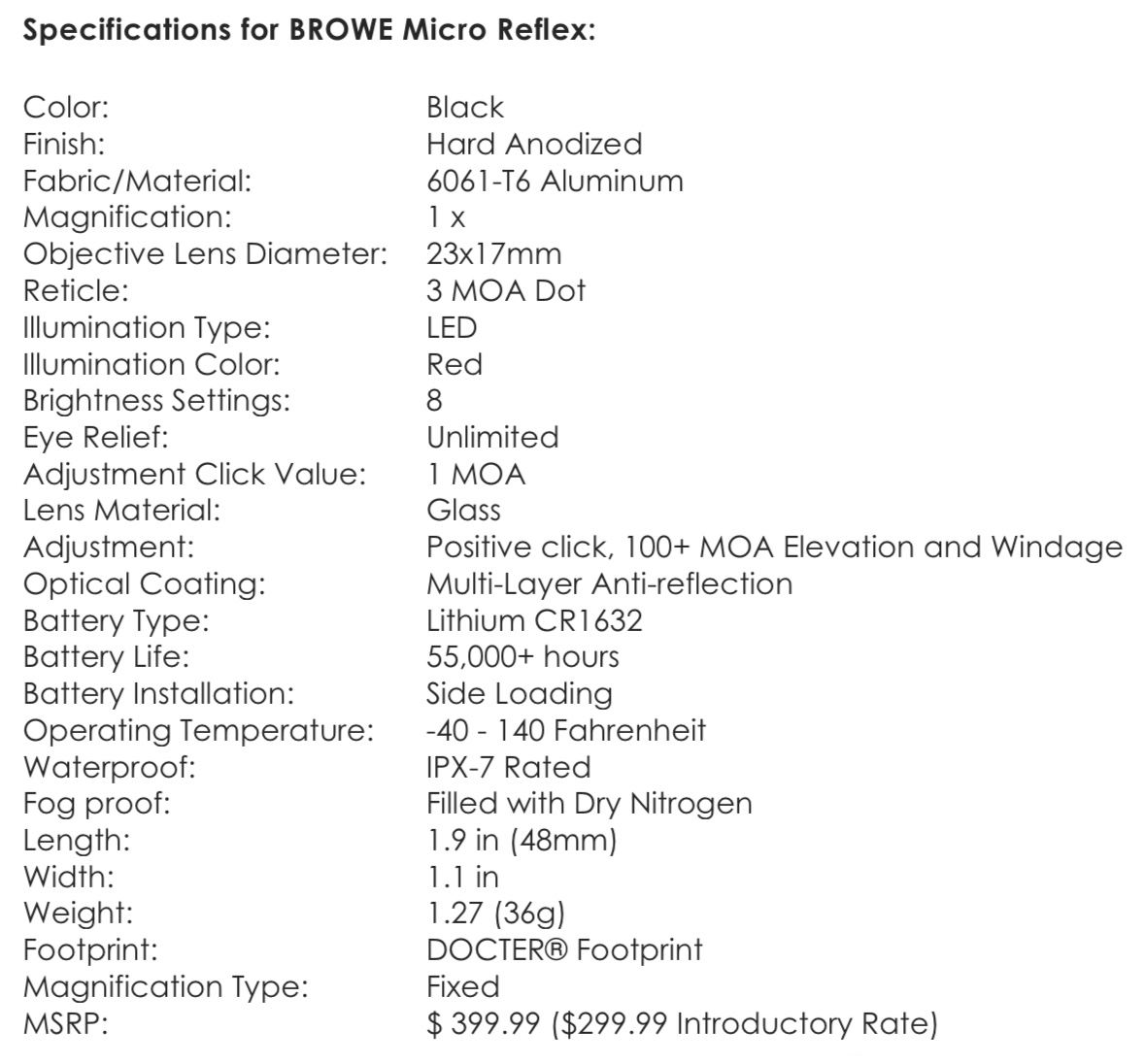

Sport Ridge® is displaying its line of Sight-In Targets that are feature-rich for Precision Rifle, AR-15, and Reflex Sight optics, plus a whole new line of reactive targets. Sport Ridge® expanded its firearm care family of hard case cleaning kits to include a 21-piece universal pistol and AR kits with a 73 inch-pound torque ratchet.

Nau says attendees will meet face-to-face with the team and discuss opportunities to enhance their retail merchandising and profitable offerings that will drive 2022 retail success!

Made By Proud Americans, TAC SHIELD® products ensure that our warriors, sworn officers, and private professionals have the finest tactical nylon gear for the world’s harshest conditions. We use MIL-SPEC materials and American manufacturing to ensure top quality. All products are backed with a lifetime warranty! Military Products Inc. brands also include SPORT RIDGE® products designed for shooters that demand “RUGGED PERFORMANCE” while in the field.

Shot Show Booth: 14427

TAC SHIELD New Products www.tacshield.com

SPORT RIDGE New Products www.sportridge.com

Schedule an appointment forms.gle/uzvAHYXG2VnQ77vp7