The Twin Hooker from Dynamic Fuzz is a simple, bungee-style cable management solution for helmets.

Offered in Black or Coyote.

www.dynamicfuzz.com/product/twin-hooker

The Twin Hooker from Dynamic Fuzz is a simple, bungee-style cable management solution for helmets.

Offered in Black or Coyote.

www.dynamicfuzz.com/product/twin-hooker

The life story of Charles Herbert Lightoller is something that there is no way you could make up. He took part in three of the century’s most memorable maritime activities, and one that is straight out of a James Bond film — that is, if Bond was 65 and with his wife on their private boat.

Charles Lightoller was born in Chorley, Lancashire, in 1874, and sailed for the first time at the age of thirteen. The Holt Hill, on which he was serving, ran aground in 1889, which was his first shipwreck at the age of 15. Before joining the White Star Line in 1900, Lightoller had a series of high-seas adventures during his childhood — overcoming cyclones, fires on board, and tropical diseases.

The White Star Line operated a fleet of ships between the United Kingdom, Australia, and the United States. On one of his visits from Australia, Lightoller would meet his wife, but it was on a trip to America that he would cement his place in history.

The RMS Titanic, the White Star Line’s supposedly unsinkable ocean liner, set sail from Southampton in 1912, with Charles Lightoller serving as the ship’s second officer. On the night of April 14th, Lightoller was already in bed after finishing his last rounds when he felt “a sudden vibrating jar pass through the ship”. After hearing that the water had already entered the mail room shortly after midnight, another officer reported to him that “we’ve struck an iceberg”, so Lightoller dressed and made his way to the deck. The ship was, as everyone now knows, completely unprepared for a tragedy of that magnitude. Even though Lightoller acknowledged that he was “fairly sure” that the Titanic would not sink, he knew that it was safer to be careful and prepared than risk the lives of the passengers who were now huddled on deck. To avoid a mass panic, he started forcing all the women and children into lifeboats and ensuring that his men-maintained order.

He cheerfully tried to convince the passengers that getting into the boats was merely “a precaution” and that “they were perfectly safe, as a ship was just a few miles away”. According to his account of that evening, he was most troubled by the band’s choice of music as they performed on deck in an effort to restore order, adding, “I don’t like jazz music in general, but I think it helped us all”.

“Women and children first” was translated as “women and children only” by Charles Lightoller, who refused to let John Jacob Astor follow his wife onto a lifeboat, telling the millionaire that “no men are allowed in these boats before the women are loaded first”.

Lightoller and his fellow officers “all shook hands and said ‘Good-bye’” before seeing off the last lifeboat when it became apparent that the Titanic was doomed.

From the deck, Lightoller plunged into the freezing water, miraculously avoiding being sucked down with the huge boat. Until the survivors were rescued, he clung to an overturned lifeboat. Lightoller was the last person to be rescued from the Carpathia, and he was the highest-ranking officer to survive the disaster.

One would think that surviving the twentieth century’s worst maritime tragedy would bring Charles Lightoller back to shore for good, but his sea adventures were far from over.

During WWI, Charles served in the Royal Navy and was given command of his own torpedo boat. He was decorated twice for his fighting efforts (including sinking the German submarine UB-110) and rose to the rank of full naval commander by the end of the Great War.

After the war, Lightoller retired, but he couldn’t fully abandon the sea. When the Germans started planning for war again, he and his wife purchased their own yacht, the Sundower, and spent the next decade cruising around northern Europe and carrying out the occasional covert surveillance mission for the Admiralty. The Royal Navy recruited the once retired veteran and his wife to carry out a series of secret missions, in an effort to obtain intelligence about the movements of the German army. The couple seemed to just be an elderly couple on vacation; it was the perfect cover. The Lightollers communicated any information they could gather and kept a watchful eye on the German coastline. She would sit on the deck of the boat and would pretend to be reading and drinking while keeping watch and he would be down below secretly taking notes and sketching the coastline.

When the war finally broke out in 1939, the Nazi war machine ripped through continental Europe, rebuffing the Allies at every turn. As France prepared to surrender, the British army, joined by French and Belgian forces, was caught between the sea and the Germans. Germany attacked in a last-ditch effort that could have ended the Western European theater of war in a single blow.

Winston Churchill and the British government devised a bold scheme to save the troops, which, if successful, would guarantee that their army would live to fight another day. On May 27th, 1940, civilian boat owners along the English coast started receiving phone calls from the government telling them that their boats were being requisitioned by the government to assist in the evacuation of Allied soldiers across the channel. When retired Commander Charles Lightoller got his phone call, he only had one condition: he decided to take the Sundower himself.

Charles Lightoller, now 66 years old, set out with his son Roger and Gerald Ashcroft, a teen Sea Scout. The Sundower paused en route to the beaches to rescue the crew of a motor cruiser that had caught fire before going on to pull 260 men aboard, all while dodging “quite a lot of attention from enemy aircraft”. “My God, mate!” exclaimed one astonished officer as the Sundower docked in England, watching the nearly endless stream of soldiers emerge from Lightoller boats. “Where did you bring them all?” says the narrator.

The adventures of Charles Lightoller during WWII would later serve as the basis for Mark Rylance’s role in Christopher Nolan’s critically acclaimed film Dunkirk.

Soldier Systems Daily; it all started with a redeye flight from San Diego to Norfolk and a copy of Wired magazine. I had wanted to start writing again and there was this article on the rivalry between tech blogs Gizmodo and Endgadget. I learned that a blog could be about something tangible and decided to use the format. Not long after, SSD was born. It started as a means to keep me off the streets at night, but within a year became a full time job. I’m so grateful to be able to do something I love.

Earlier this week we hit our 13th year of existence, publishing a daily website. Naturally, hard at work publishing daily, we missed the anniversary. So here we are, patting ourselves on the back a few days late.

We’ve been fortunate to outlast most of the competition and the past 14 months of “just 14 days to flatten the curve,” have made it tough. But the truth is, we wouldn’t exist without our loyal readers and fantastic advertisers. Many of them are small business owners, feeling the pinch of these tough times like everyone else. Please support them when you get a chance and keep reading; daily, it’s in the name.

Eric Graves

Editor

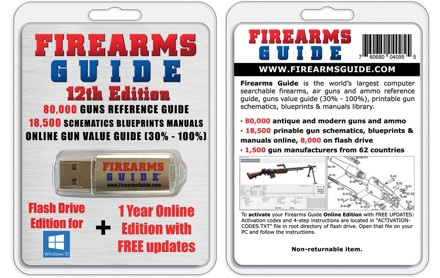

Impressum Media Inc., Los Angeles, CA – May 09.2021 – Firearms Guide, the largest gun guide, gun values guide and gun schematics & manuals library just published its Online and Flash Drive 12th Edition.

“The New Firearms Guide Flash Drive 12th Edition is published as a cloud-based Online Edition and a as off-line Flash Drive Edition for Windows. It is the world’s largest searchable guns & ammo reference guide that presents over 80,000 antique and modern firearms, air guns and ammunition from 1,500 manufacturers from 62 countries. It covers all types of guns from the oldest black powder muskets to American classic guns to the newest 2021 guns. Users can search the guide by caliber, type of action or stock, by year of production, country of origin, or any other way and will get all the tech specs, prices, features and up to 12 high-resolution pictures per gun. That is the reason why Firearms Guide is used by many police forces around the world as a firearms identification tool” says Chris Mijic, publisher of Firearms Guide. “If you are a gunsmith you will love the fact that the new 12th Edition has over 18,500 printable high-resolution gun schematics, blueprints, manuals and antique catalogs that you can check on your computer or tablet and you can print them out when you work on a client’s gun.” All that material is available to gunsmiths online 24/7 or off-line with Flash Drive for Windows computers.

“Many Firearms Guide users love the fact that they can use the Flash Drive Edition offline, completely anonymously, without Google or any search engine or internet provider tracking and archiving their gun related searches that they can later sell to any client or deliver to the government” says Chris Mijic, publisher of Firearms Guide. The Flash Drive Edition keeps privacy private.

Published since 2009 for shooting industry professionals and gun enthusiasts, with its new 12th Edition published as Online Edition at www.FirearmsGuide.com and as Flash Drive Edition, Firearms Guide is:

1. A Reference Guide that presents over 80,000 antique and modern firearms, air guns and ammunition from 1,500 manufacturers from 62 countries.

2. A Gun Value Guide that presents antique and modern guns with gun values online based off of the 100% – 30% condition ratings

3. A Gun Schematics, Blueprints & Manuals Library with 18,500 printable hi-res gun schematics, blueprints, catalogs & manuals for all types of antique and modern guns & ammo.

Firearms Guide Flash Drive 12th Edition is available in a combo with the Online 12th Edition and with free updates at www.firearmsguide.com

FORT GREELY, Alaska — Paratroopers with 4th Infantry Brigade Combat Team (Airborne), 25th Infantry Division, conducted an airborne operation May 11, 2021, onto Allen Army Airfield, Fort Greely, Alaska, as part of Northern Edge 2021.

Following the seizure of the airfield, an M142 High Mobility Artillery Rocket System (HIMARS) battery from the 17th Field Artillery Brigade out of Joint Base Lewis-McChord arrived and conducted a live fire exercise at nearby Donnelly Training Area.

Approximately 300 paratroopers from the 1st Battalion, 501st Parachute Infantry Regiment, out of Joint Base Elmendorf-Richardson, Alaska, exited from U.S. Air Force C-17 Globemaster III and C-130 Hercules aircraft while A-10 Thunderbolt IIs orbited, providing close air support. Once on the ground, paratroopers moved to their assembly areas to consolidate and secure the airfield as additional C-130s and C-17s landed with more paratroopers, equipment and the HIMARS battery.

The HIMARS battery with 5th Battalion, 3rd Field Artillery Regiment, was air transported from Cold Bay, Alaska, and fired a full volley of rockets that demonstrated the ability of the joint force to quickly build and implement combat power.

Conducting a JFEO as part of a joint operation is nothing new to the Spartan paratroopers who train for operations like this all year long.

“We’ve been doing this for a long time, and each paratrooper knows their role,” said Maj. Michael Conforti, the operations officer for 1-501st PIR. “You never know if an aircraft will have a mechanical issue, or someone will get injured, so the key to success is that each paratrooper also knows the jobs and duties of everyone else around them.”

Understanding the role of adjacent units and enhancing the ability to work together are key components of exercise NE21.

NE21 is a U.S. Indo-Pacific Command sponsored, Headquarters Pacific Air Forces led U.S. joint field training exercise scheduled for May 3-14, 2021, in locations in and around Alaska that uses realistic scenarios to improve joint combat readiness.

The Spartan Brigade is the only airborne infantry brigade combat team in the Indo-Pacific Command and provides the combatant commander with the unique capability to project an expeditionary force by air across Pacific and Arctic regions.

By MAJ Jason Welch

Here’s mother one from Jacobite Solutions. The PALS SOLAS Board carries 4 x mini (1.5″) Cyalume sticks while only taking up a single PALS loop.

Also available for single sticks attached via Velcro or PALS.