Fully operational demonstrator will showcase multi-domain sensor fusion, autonomous mission management, and Edge-to-Mission Command (E2MC) capabilities.

MARSS, a technology company already protecting millions of lives across the globe, is bringing a live fully operational NiDAR demonstrator to the upcoming World Defense Show in Riyadh from 8-12 February. Visitors to the MARSS stand will get hands-on experience with the system, exploring how NiDAR transforms layered multi-domain defence operations.

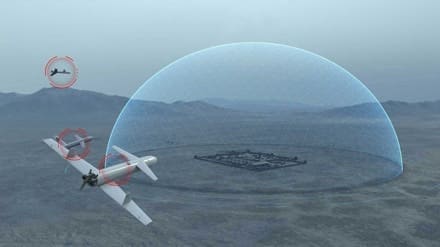

Already operational at more than 60 sites worldwide protecting critical civilian infrastructure and military assets, NiDAR is a complete C4I platform that fuses data from numerous sensors into one unified operational picture. The system is sensor and effector agnostic, seamlessly integrating both legacy systems already in the field and the latest best-in-class equipment across radar, RF, EO/IR, sonar, and many more sensor-types.

Backed by over 20 years of operational experience and one of the largest threat datasets in the world, NiDAR’s AI-enhanced platform autonomously detects, tracks, classifies and prioritises threats and recommends optimal countermeasures to operators in real-time and across all domains.

By consolidating sensor data and mission support into a single intuitive interface, NiDAR dramatically reduces operator burden. Where traditional systems require multiple operators across all different sensor feeds, NiDAR can be operated by a single person.

Able to hand-off directly to soft-kill and kinetic effectors from the same single interface, the platform dramatically accelerates sensor-to-shooter timelines. In providing an end-to-end kill chain capability, NiDAR reduces the decision cycle from minutes to seconds across detection, classification, and defeat of asymmetric threats. This compressed timeline is critical in modern defence operations where speed of response can determine mission success – particularly when addressing swarm attacks and other coordinated drone threats.

At the World Defense Show, MARSS will also demonstrate the latest enhancements to NiDAR, including:

NiDAR Autonomous Mission Management (AMM) – enabling operators to autonomously task, and deploy uncrewed assets across air, land, and sea domains, transforming UAVs, UGVs, and USVs into intelligent autonomous sensors and effectors within the wider defence ecosystem.

NiDAR Nation Shield – the world’s first “E2MC” C4I platform, providing a single, coherent operating picture across all tiers of operations. From tactical edge personnel using ruggedised tablets through to strategic command centres with 360° display capabilities.

The MARSS team will also share updates on recent contract wins with GCC, NATO and Indo-Pacific states, reinforcing the platform’s growing role in protecting what matters most to warfighters: people, critical infrastructure, and assets across the globe.

Rob Balloch, Chief Growth Officer at MARSS, said: “The World Defense Show provides the perfect platform to demonstrate how NiDAR has evolved beyond a traditional C2 to a complete C4I ecosystem. With our focus on sensor fusion, autonomous mission management, and unified command architecture, we’re addressing the critical challenges facing modern defence: doing more with fewer personnel while accelerating decision-making from minutes to seconds.”

Robbie Draper, Director of Operations at MARSS, added: “This isn’t a static display – visitors can get hands on with a live, fully functional NiDAR system – and see for themselves how we’re transforming layered multi-domain defence operations. From the tactical edge to strategic headquarters, NiDAR delivers the single operating picture that commanders have never had before.”

To experience NiDAR’s capabilities first-hand, visit the MARSS stand on the UK Pavilion, H1-H40, at the World Defense Show 2026.