PICATINNY ARSENAL, N.J. – The U.S. Army has established the Portfolio Acquisition Executive for Agile Sustainment and Ammunition, PAE AS&A, at Picatinny Arsenal under the command of Maj. Gen. John T. Reim. The move is a key part of broader Continuous Transformation efforts intended to increase efficiency and accelerate the delivery of critical capabilities to the warfighter.

The new organization was activated at a ceremony held on January 20 at Picatinny Arsenal where several thousand team members from all involved organizations were introduced to the new command. The Assistant Secretary of the Army for Acquisition, Logistics and Technology, the Honorable Brent Ingraham, presided over the ceremony and spoke to the significance of the new organization as a key part of the Army’s Acquisition reform initiative.

Following the ceremony, Ingraham witnessed a live demonstration featuring the Purpose Built Attritable System and a TRV-150 drone dropping smoke and a M69 training grenade onto a target simulating a small group of enemy Soldiers with a vehicle. This showed off one of DEVCOM’s latest innovations, the Picatinny Common Lethality Integration Kit or Picatinny CLIK. These are just a few of the of lethal UAS and counter-UAS technologies being developed by U.S. Army Combat Capabilities Development Command Armaments Center. The DEVCOM Armaments Center now serves as the Systems Center, a key enabler, of the PAE AS&A.

Subject matter experts from the PAE AS&A and DEVCOM Armaments Center then also briefed Ingraham on other lethal UAS, counter-UAS munitions, advanced artillery, next-gen energetics, expeditionary logistics and supply chain enabling systems that are the result of joint efforts of the two Picatinny based organizations.

“This marks a significant milestone in our journey to modernize Army Acquisition,” Ingraham said as he addressed the audience. “We are combining the capabilities of the Joint Program Executive Office for Armaments and Ammunition with critical combat logistic capabilities from PEO Combat Support and Combat Support Services to ensure fully capability alignment under our new structure.”

“Today we turn the page to an exciting new chapter in Army Acquisition,” Ingraham continued. “Every role in the organization plays an invaluable part in this journey. Cross organization engagement and agility are essential in ensuring the success of this transition. The future of Army Acquisition is bright and PAE AS&A is poised to lead the way.”

Ingraham’s visit underscored the installation’s vital role the various commands at Picatinny Arsenal play in maintaining readiness — delivering the capabilities, expertise, and innovation that ensures our Warfighters and allies are equipped to succeed in any environment.

“As we embark on this journey, we align our actions with the strategic guidance provided by our leadership including the President of the United States, the Secretary of War, the Secretary of the Army and the Chief of Staff of the Army,” said Reim who followed Ingraham. “This initiative is not merely a restructuring of our acquisition processes. It is a fundamental rethinking of how we approach the delivery of capabilities to our Soldiers, our joint warfighters, and our international partners.”

Legacies of Excellence

The Army is fundamentally restructuring its acquisition process to prioritize speed and efficiency over traditional approaches. As part of this initiative, the Army is establishing six Portfolio Acquisition Executives with increased focus on capabilities over specific programs.

The transformation includes the integration of the former Program Executive Office Combat Support and Combat Service Support, PEO CS&CSS, into the Capability Program Executive for Combat Logistics, CPE CL, led by Brig. Gen. Camilla White. PEO CS&CSS brings an unmatched history of logistics and sustainment support to the new CPE CL. It encompasses more than 200 programs spanning the Army’s transportation, ordnance, quartermaster, engineer, and training equipment portfolios.

As the CPE CL, it will continue to develop and deliver modernized tactical wheeled vehicles, engineering equipment, watercraft, power generation systems, and other force sustainment capabilities to Army, Joint, and global partners.

At the same time, the Joint Program Executive Office for Armaments and Ammunition, JPEO A&A, will realign into the Capability Program Executive for Ammunition & Energetics, CPE A&E, led by Col. Jason Bohannon. JPEO A&A has consistently delivered innovative acquisition solutions to provide Joint Warfighters and allied partners with overmatch capabilities. The JPEO was comprised of four project offices covering Combat Ammunition Systems, Close Combat Systems, Maneuver Ammunition Systems and Joint Services.

As the CPE A&E, it retains responsibility for life-cycle acquisition management of all conventional ammunition, which includes integrating budgets, acquisition strategies, research and development and life-cycle management across all ammunition families.

CPE CL will be headquartered at Detroit Arsenal, Michigan, while CPE A&E will remain at Picatinny Arsenal. Unlike the previous Program Executive Offices, each PAE will have comprehensive responsibilities and accountability for managing the full spectrum of acquisition activities, including requirements development, technology maturation, product development, testing, contracting, fielding, sustainment, and international sales. This flattened acquisition system empowers PAEs to make timely, risk-based decisions and accelerates capability delivery to Warfighters through problem-focused requirements, smarter contracts, informed risks, and faster pivots.

“This restructure achieves unity of command by establishing and empowering PAE AS&A with the full authority to direct research and development, prototyping, testing, production, and sustainment,” said Reim. “By prioritizing outcomes over processes, this new construct empowers us to award contracts faster by cutting through bureaucracy. Overall, this approach unburdens the acquisition enterprise and allows us to deliver warfighting capabilities at speed and scale.”

Accelerating Ammunition Acquisitions

Under the leadership of Maj. Gen. Reim, PAE AS&A will oversee an entire capability area including all conventional ammunition requirements including direct and indirect fire ammunition, close combat systems, explosives, and pyrotechnics, in addition to logistics, fielding, and sustainment. PAE AS&A will have oversight of the organic munition production facilities.

Maj. Gen. Sean Davis will serve as the new Deputy Portfolio Acquisition Executive adding the sustainment capabilities of the Army’s Combined Arms Support Command, CASCOM to PAE AS&A. CASCOM trains and develops adaptive Sustainment professionals for the total force while integrating innovative Army and Joint Sustainment capabilities, concepts and doctrine to sustain large scale combat operations in a multi-domain operations environment. It is also a part of Transformation and Training Command and is located at Fort Lee, Virginia. PAE AS&A is committed to supporting the warfighter through an innovative approach to ammunition acquisition and sustainment that leverages existing authorities to deliver tangible benefits, including accelerated capability delivery, smarter contracts, and informed risk management.

In addition to the two new CPEs, PAE AS&A will oversee multiple acquisition enablers including senior contracting officials, a test and evaluation integrator, the Sustainment Future Capability Directorate and the system center lead overseeing coordination among Army Combat Capabilities Development Command Centers. The PAE AS&A System Center Lead is Chris J. Grassano, the firector of the DEVCOM Armaments Center. The new structure will enable holistic management of conventional ammunition development, production and sustainment under a single command resulting in increased efficiencies and accelerated delivery of lethality aligned with the emerging Army Warfighting Concept.

Looking Ahead

In conjunction with this reform, the Army is investing $1.1 billion per year to overhaul depots, arsenals, and ammunition plants that produce and sustain Army equipment. This commitment will not only modernize facilities but also strengthen the defense supply chain and create jobs.

For industry partners, these reforms will mean faster contracts, clearer points of entry, and fewer bureaucratic hurdles. Soldiers will benefit from receiving new capabilities, such as drones, long-range fires, and next-generation command and control systems, years faster than before.

By Michael Chambers and Eric Kowal

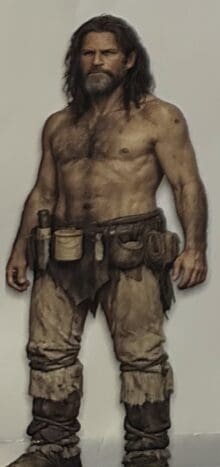

The naming of Blue Force Gear’s new belt pouch innovation was inspired by Ötzi the Iceman, a 5,300-year-old Copper Age traveler discovered in the Alps and proclaimed the oldest and best-pre-served, naturally mummified human ever documented. Preserved in glacial ice, Otzi was found wearing a modular belt outfitted with equipment like a knife sheath, food/medicine pouch, and fire-start-ing kit. It stands as the earliest known example of a tactical belt, a testament to how long warriors have trusted a well-built waist rig to keep mission-critical gear exactly where it needs to be.

The naming of Blue Force Gear’s new belt pouch innovation was inspired by Ötzi the Iceman, a 5,300-year-old Copper Age traveler discovered in the Alps and proclaimed the oldest and best-pre-served, naturally mummified human ever documented. Preserved in glacial ice, Otzi was found wearing a modular belt outfitted with equipment like a knife sheath, food/medicine pouch, and fire-start-ing kit. It stands as the earliest known example of a tactical belt, a testament to how long warriors have trusted a well-built waist rig to keep mission-critical gear exactly where it needs to be.