“A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.”

— Robert Heinlein

I believe in that Heinlein quote (above). I have tried to live my life that way. I recommend it. My first article on SSD was posted on 1 March 2015. At the time, I fully expected it to be one and done. Now, ten years and 59 articles later, it is time for me to take a new direction. Therefore, this will be my finalsubmission here – or anywhere else. I am proud of the articles that have been posted on SSD and – in some cases – reposted on other sites. I have been and always will be grateful to Eric for allowing me to rant and rave on his industry platform. He has been a great friend.

People and times must inevitably change. In the last year plus, I have been traveling considerably more often than I have since I retired in 2011. I have been putting myself back out there professionally and reconnecting with various associates and teammates. This outreach was prompted by some recent losses among my close friends. Specifically, four Command Sergeant Majors that I served with since the early 90s and had known for over 30 years. They all died of various cancers in the last two years. Two were younger than me.

I celebrate their lives and service, but their passing was a stark reminder of my mortality. I realized there were still constructivethings I wanted to do in the time left to me. Writing episodically like I have been, was not one of those things. That said, I am going to do something that I have been reluctant to do – in fact, I stated that I would not do it. I will consolidate these SSD articles into a book that I will self-publish sometime later this year. It now seems like the best way to close out this chapter of my life appropriately.

What I want to concentrate on are opportunities to teach, coach, and mentor some of the next generation of Army leaders. To that end, I have been down to The Army’s Officer Candidate School (OCS) three times since I wrote an article on OCS last August. I will go down again in June and about every 9-10 weeks thereafter. Each time, I spend a week at the school preaching the gospel of leadership to the heathen OCS Candidates – and sometimes the Cadre too.

I am going to keep doing that as long as I am able and the leadership of the school is willing to put up with me. In fact, this summer I am going to ask the OCS Alumni Association to recruit 2-3 more folks to join in some kind of rotation so that we can have better coverage of the classes than one person can provide. OCS Candidates are leadership sponges. They will take in anything and everything they can get.

I am working on getting something similar going (virtually for now) with the ROTC Cadets at Norwich University in Vermont. I will be joining a couple of still-serving Green Berets on a video conference to talk to Cadets about SF/SOF opportunities in early April. Hopefully, that can become a routinely scheduled interaction in the future. Later in April, I expect to be back at SWCS for a week doing the same sort of thing.

In May and again in September, I will visit Fort Cambell and spend time with the 5th Special Forces Group and the Air Assault School as I have done for the last few years. I will take every opportunity that I can find or manufacture to stay “plugged in” and do some professional mentoring. It is always a good use of my time. Whether it is any value added for my target audiences is for them to judge. To be clear, I am not paid for my time or travels. All I have asked for in return is continued access; and so far, I have been successful in getting that cooperation from the various commands. I just have to keep earning that privilege. I suppose doing it “pro bono” confirms that I am still a soldier, not a businessman. I can live with that.

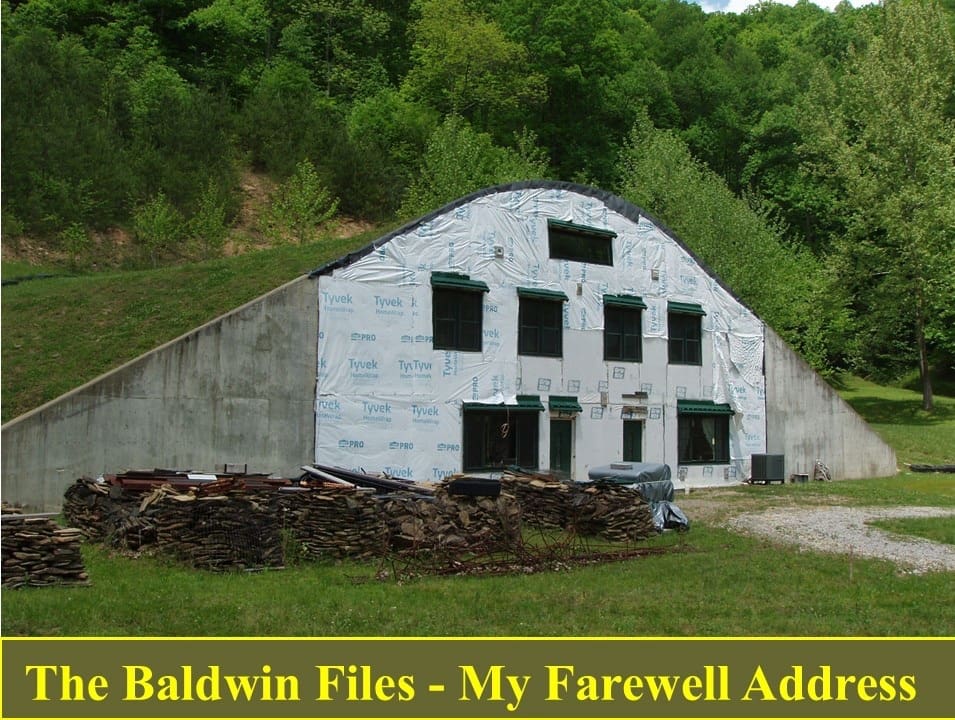

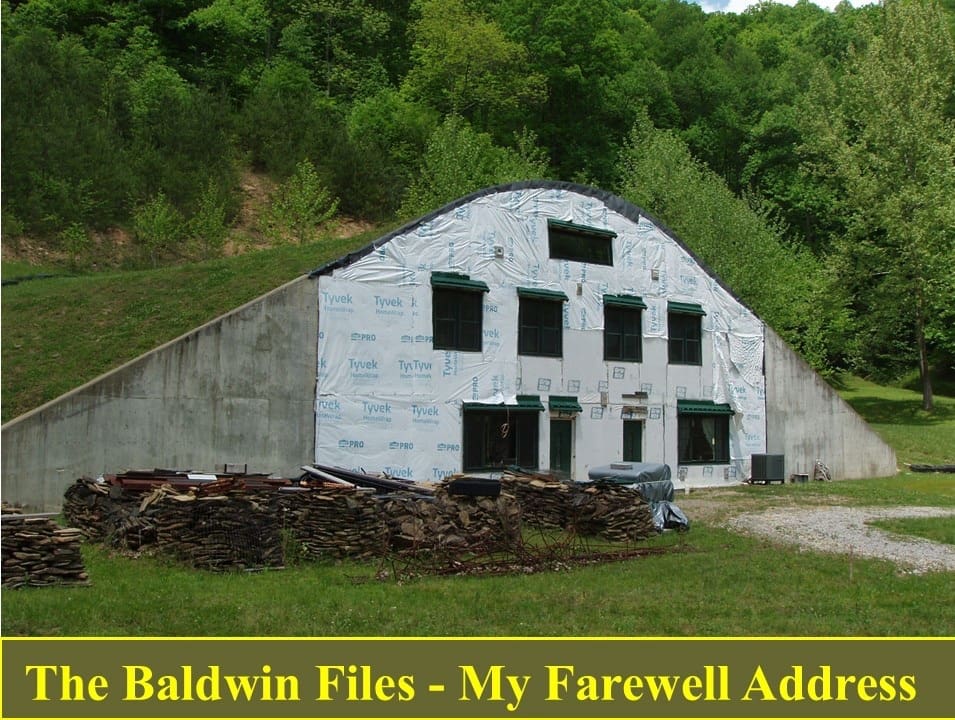

The pictures that accompany this piece show some aspects of the 56-acre “Homestead” I have been working on these last 13 years since I retired. While the façade is, obviously, unfinished, the interior is almost done. Those pallets in the first picture are the stones that eventually will be on the front of the dome just like they already are on the garage (2nd Picture). This is my physical “farewell address” if you will. It may or may not be of interest to the regular readers of my articles. My friends joke that I won’t live long enough to finish it at the snail-like pace I appear to be working. They might be right. Some have speculated that it is imaginary. A couple of my friends have seen it as a work in progress over the years, but these pictures should also prove to those who have not that it does exist!

My wife and I have our office space and library on the second floor of the 3-Bay garage on the right of the second picture. I designed both buildings myself and, therefore, the interior layouts are customized to our preferences. We have had plenty of professional and semi-professional help building our dream home, but she and I have indeed touched every inch of it as it has gone up. It is ours. And, because I have been paying as we go, I owe nothing on any of it. Slowly but surely, the plan has come together. Still, getting this home fully finished is definitely moving to the front of my priorities now as well. It is past time.

These pictures are over a year old and there have been a number of improvements since then. For example, I got the rails up on the stairwell not too long ago (not shown). The bar (3rd and 5thpictures) was a “housewarming” gift from my youngest Brother a few years back. He bought it for $50 at a flea market. It was intact but in bad shape when we got it, but my wife and I refurbished and fully stocked it. That Brother had worked in construction all his adult life. He was heavily involved in all aspects of this long project.

He died of lung cancer about 4 years ago. His loss set our schedule back quite a bit. It took me a long time to come back to the project at all. To fill the blank space between the stairwell and the kitchen (3rd Picture), I have someone – with more woodworking skills than I – building me a custom display case for my guns. Every real Hillbilly knows that your firearmsshould never be stored too far from your liquor. My Brother would like it that way and I think the friends I have lost would too. Here’s to all of them.

When I close out with an OCS Company, I tell them goodbye and good luck. Then I say that it is “traditional” for an old person to tell youngsters how much we envy the journey in front of them and tell them that we wish we could do it all over ourselves. I go on to say that I am sure that most folks who do soare sincere. But if I said it, it would be bullshit! I tell them that I do NOT envy them. I would not take their place and start over even if I could. I do not need a do-over. I have run my race. I am satisfied with my career and my life. I can only hope and wish for them that when they finish their careers – however, short or long that might be – they will be as satisfied as I am now. For those reading this, I would wish the same.

I have been blessed with great good luck my entire life. Although I did not always recognize it in the moment. It is demonstrably true; I am one lucky Sumbitch. Like the Starship Troopers (the book, not the movie) protagonist Juan “Johnny” Rico, my luck has always been people. I have had countless great mentors, role models, and teammates. Not to mention that I have almost exclusively worked with truly high-performance people. People you can count on and trust. People who never quit growing and improving. People who thrive on challenges. Being associated with people like that has made me a better person. Therefore, I have had very few disappointments of any kind in my life, and in terms of my professional journey, Je Ne Regrette Rien! I regret nothing.

In conclusion, and to paraphrase McArther and Chesty Puller, I am not fading away just yet, but I am choosing to attack in another direction! One final thought on leadership. A leader keeps moving ahead and must blaze his or her own path forward. Poor leaders cut a path only wide enough for themselves to pass through. Good leaders cut a wider opening to bring their organization forward with them. The best leaders cut the widest lane possible. If you fancy yourself a leader, a good leader, cut that wider path. Show those that follow you how it is done.

De Oppresso Liber!

LTC Terry Baldwin, US Army (Ret) served on active duty from 1975-2011 in various Infantry and Special Forces assignments. SSD has been blessed by his friendship and role as both reader and contributor. We encourage him to remain engaged with our readership through our comments section and we expect to continue our phone calls and correspondence.