LAS VEGAS, NV. – Blue Force Gear, Inc., the world leader in load carriage equipment innovation, unveils at the 2026 NSSF SHOT Show a collection of products that continue to challenge currently set standards. From a revolutionary integrated battle belt climbing system to signature-reduction and life-saving gear, BFG continues to engineer solutions that professionals didn’t know they needed, until now. SHOT Show attendees can explore the following cutting-edge gear, as well as the rest of Blue Force Gear’s legendary product line, at BFG’s booth #20405 where specialists will demonstrate their unique capabilities.

Integrated Stealth Harness (ISH™): From Climber to Gunfighter in Seconds

The patented ISH Harness combines a gun belt, climbing harness, tourniquet, and travel restraint allinto one lightweight, certified system rated to hold over 3,000 pounds. Modular, removable leg loops deploy in seconds and feature windlass points for emergency tourniquet application or rappelling friction hitches. The ISH Harness features BFG’s signature MOLLEminus platform and anatomical curve design for uncompromising comfort on the ground or at height.The ISH Harness is UIAA and EU Certified as a Type C Mountaineering Harness.

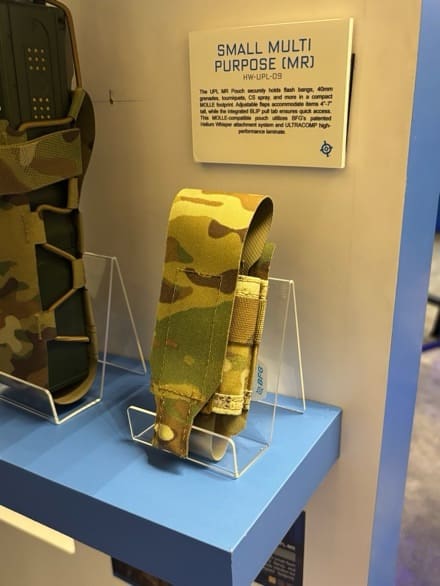

UPL MR Pouch: Maximum Versatility, Minimal Footprint

This compact pouch securely organizes everything from 40mm grenades and CS Spray to tourniquets and spare mags in just 2″ of MOLLE space. Adjustable flaps accommodate items from 4″ to 7″ in height, while the integrated BLIP pull tab ensures quick access in any conditions. Built with ULTRACOMP laminate, the MR Pouch reduces weight by up to 60% without sacrificing durability.

MTKN!® Nano LE: Life-Saving Capacity in a Compact Package

Despite its streamlined design, the Nano LE matches the capacity of the Micro Trauma Kit NOW!, holding QuickClot Gauze, Mini Compression Dressing, Hypothermia Blanket, and more depending on the fill level chosen. Two integrated sidecar pouches secure NARCAN Nasal Spray and a tourniquet, while single-hand BLIP pull tab access ensures rapid and consistent deployment. The Nano LE mountshorizontally or vertically on MOLLE or pants belts for ultimate flexibility.

BNVD Pouch & Slipcover: Signature Management and Convenience

Born from GWOT lessons learned, BFG’s BNVD Slipcover addresses a critical operational need: signature reduction. The lightweight Slipcover masks the distinctive BNVD shape with a shaggy design built out of nylon spandex while also providing natural face-shading. The perfect companion to the Slipcover, the BNVD Pouch delivers padded protection with a Fastex Buckle closure and MOLLE-compatible Helium Whisper pouch attachment. Together, they provide seamless protection from arms room storage to deployment.

For more information about Blue Force Gear or any of their product offerings, visit their website: www.blueforcegear.com

About Blue Force Gear®

Blue Force Gear designs the best weapon slings and leads the lightweight load carriage equipment revolution with Ten-Speed multi-use pouches, MOLLEminus platforms, and the patented Helium Whisper attachment system. Their proprietaryULTRACOMP high-performance coated fabric laminate material, unrivaled innovation, and attention to detail set Blue Force Gear apart from others in the tactical equipment industry. Blue Force Gear is a Great Place to Work Certified Company. For more information, visit their website: www.blueforcegear.com