FORT BENNING, Ga. — The U.S. Army Ranger Course has served as the Army’s crucible for developing the functional skills and mental toughness required of platoon and squad leaders in close combat for three-quarters of a century. The course marked its 75th anniversary on Nov. 25, 2025, affirming its vital, continuing role in creating adaptive and decisive leaders for the modern force.

Honoring the Legacy

The celebration, hosted by the Airborne and Ranger Training Brigade, began with the dedication of the Col. Ralph Puckett Jr. Memorial, marking the official kickoff of the anniversary observance. This statue now resides near Hurley Hill, within Camp Rogers, a location described by retired Brig. Gen. Pete Jones as a “sacred place for generations of Rangers” seeking to earn the coveted tab. Puckett’s lifelong dedication was not just to the fight, but to his troops. The statue, depicting the colonel at attention and saluting, fulfills his specific wish to be positioned “overlooking Ranger graduations,” a detail shared by retired Col. Rob Choppa. This ensures that as candidates begin their intense journey, they appreciate the benefactor whose standard they strive to meet. Puckett, who organized and led the first Ranger company in the Korean War, embodies the selfless courage and resolute leadership that remain the core requirement for every graduate.

Maneuver Center of Excellence Commander, Maj. Gen. Colin P. Tuley, emphasized Colonel Puckett’s profound influence: “The generations of Soldiers mark their encounter with Colonel Puckett as pivotal to their journey toward leadership.” Tuley noted that Puckett believed that you could take good men and “by combat-focused, realistic, high-standard training, turn them into combat infantrymen, effective Soldiers, Rangers.” Tuley added that the course reveals true character, stating about Puckett, “The Battle at Hill 205 didn’t make him who he was—it revealed who he was.”

Evolution of the Crucible

The core mission of the Ranger Course—to develop leaders who perform effectively under extreme stress—remains unchanged, but the curriculum has undergone significant, necessary adaptation since its formal origin in 1950 during the Korean War. The course began with the formation and training of 17 Airborne Ranger companies, including the first and only all-Black Ranger Company—the Second Ranger Company—which served with distinction.

Originally a 59-day program, the course length and content have shifted repeatedly to meet the demands of the global strategic environment. Ranger training became mandatory for all Army officers in 1967 during the Vietnam War before returning to a volunteer status in 1972. Originally established as The Ranger Department, the training structure was managed by various committees until 1987. These specialized committees included the Morgan Team (City Week), the Darby Committee, the Rogers Team, the Light Leaders Course, the Long Range Surveillance Leaders Course, Merrill’s Platoon, and B.co Rangers. The Department evolved into the current ARTB structure in the late 1980s, eventually consolidating its operations at Camp Rogers after the formation of the 4th Ranger Training Battalion in 1987. The changes were always reflective of the threats facing the nation; for instance, a dedicated desert phase was notably added in the 1980s before being removed in the mid-1990s as strategic focus shifted.

The Ranger Course remains the premier small-unit tactical leadership course precisely because of its commitment to evolution and continuing relevance. A critical shift occurred in 2015 when the course was permanently opened to women, following the successful completion by Capt. Kristen Griest and 1st Lt. Shaye Haver. Today, the course is set at 62 days and retains its brutal efficacy across three distinct phases: Darby (patrolling fundamentals), Mountain (terrain-specific operations), and Swamp (waterborne and sustained logistics), ensuring that every graduate, regardless of gender, can execute complex dismounted operations anywhere in the world.

The Enduring Standard

Reflecting on his graduation in 1979, retired Command Sgt. Maj. Jerry Klein (Ranger Class 6-79) provided a clear perspective on the internal transformation and enduring standards of the course. Klein emphasized that the fundamental requirement is not simply to meet basic physical and tactical metrics. While proficiency is essential, the true difference between Rangers and other Soldiers is the conditions under which Rangers perform and operate. “Ranger standards are Army standards, Klein explained, however, “ARTB deliberately heightens the difficulty of the training, intentionally making the circumstances far worse than anyone can imagine.” This is not arbitrary cruelty; it is a vital part of the curriculum.

This focus on internal resilience and condition-based leadership is precisely why the core of the Ranger Course has remained constant throughout the last 75 years. The essential objective has never changed: to guarantee that a leader, deprived of sleep, food, and comfort, can still execute the mission, maintain discipline, and prioritize their Soldiers. The Ranger Course is not designed to measure existing knowledge; it is designed to measure character, resilience, and the capacity for moral and physical endurance—qualities that are essential in every conflict, regardless of the technology or strategic era.

Looking to the Future

Following the Puckett statue dedication ceremony, the celebration transitioned to a large family day at Camp Rogers. This included a 5K run, a cornhole tournament, and various family activities, all supported by live music and food vendors. Concurrently with the family events, the ARTB provided interactive displays demonstrating the course’s history and current training methods. These displays, managed by the brigade’s four training battalions (4th, 5th, and 6th Ranger Training Battalions, and 1st Battalion, 507th Parachute Infantry Regiment), highlighted equipment, training vehicles, waterborne capabilities, and the abilities represented within the ARTB, with 6th RTB also providing demonstrations featuring reptiles. Retired Master Sgt. Max Mullen, a Ranger Hall of Fame inductee, reminded attendees of the course’s rich history, stating simply: “The past is power to the future.”

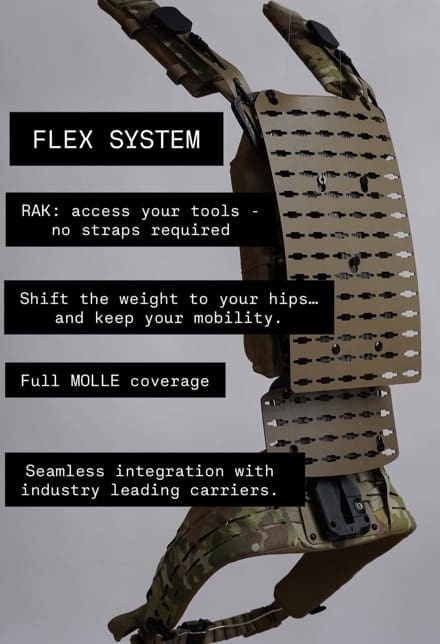

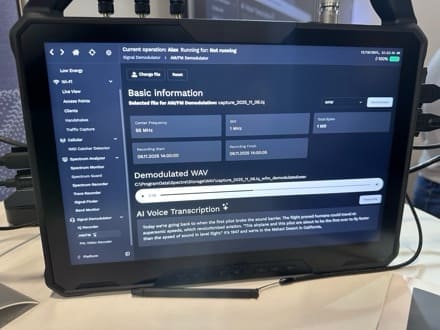

Col. Stewart C. Lindsay, ARTB commander, tied the anniversary celebration to the course’s forward vision. He noted that while the fundamentals remain unchanged, Ranger training must prepare leaders for an operating environment that is “faster, more complex and more technologically enabled” than anything that has come before. Lindsay detailed modernization efforts, including digitizing student tracking and issuing new night vision devices. He also highlighted a crucial return to foundational Soldier skills: the reintroduction of direct combat training events like combatives (hand-to-hand combat) and the bayonet assault course, both slated for implementation by April 2026. Lindsay stressed that these changes are essential, not cosmetic, as the next fight will demand Rangers who can operate in contested airspace, denied communications, and under constant surveillance. He concluded by affirming the mission’s enduring relevance: “Ranger training matters. It will matter even more in the future. When the next fight comes – and it will – our nation will once again call on Rangers, and Rangers will answer the call as they always have. We’ll lead the way.”

Seventy-five years on, the Ranger Course continues its vital role of transforming volunteers into highly capable leaders, ensuring the Army maintains decisive combat power at the small-unit level—a relevance that remains absolute in the modern, complex battlefield.

By CPT Stephanie Snyder