- Bavarian State Minister of the Interior Joachim Herrmann becomes patron of IWA OutdoorClassics 2026

- IWA Vision: Between Survival and Crisis Preparedness – What Visitors Can Expect at IWA 2026

IWA OutdoorClassics, the world’s leading exhibition for hunting, shooting sports, outdoor equipment and civilian security, is once again placing a highly relevant societal topic at the center of its focus this year. Under the overarching theme “From Survival to Crisis Preparedness – Opportunities for the Trade,” IWA Vision explores the growing public interest in personal resilience, emergency planning and sustainable security solutions. With the patronage assumed by Joachim Herrmann, Bavarian State Minister of the Interior, the discourse surrounding these issues gains additional relevance and political context.

Political Relevance of the Focus Topic

The public debate surrounding crisis preparedness, power outages, supply shortages and personal security strategies has gained significant momentum in recent years. This became especially evident when a power outage in Berlin in January 2026 demonstrated how quickly essential services can reach their limits — and how crucial robust emergency plans have become for both the population and critical infrastructure. Against this backdrop, IWA OutdoorClassics is pleased to receive political support: Bavarian Minister of the Interior Joachim Herrmann is assuming the patronage of IWA OutdoorClassics 2026. This decision underscores how firmly the topic of crisis preparedness has become anchored in political discourse and how relevant the role of the specialist trade has become in this context.

Minister of State Joachim Herrmann, Member of the Bavarian Parliament – Bavarian Minister of the Interior, for Sport and Integration and patron of IWA OutdoorClassics 2026.

More and more retailers and manufacturers are recognizing that these developments are creating a market shaped by great responsibility, increasing demand for information and clear opportunities for high quality products and professional consulting. Joachim Herrmann explains: “For decades, IWA OutdoorClassics has represented a highly professional, responsible and innovation?driven industry. Today, the focus extends far beyond products for hunting and shooting sports — topics such as civilian security, resilience and supply capabilities are increasingly shaping the public debate. Especially in times when national and international events remind us how vulnerable modern infrastructures can be, crisis preparedness is gaining in importance.

Qualified specialist retailers play a central role in this context: Many hunting and shooting sports retailers already take on essential responsibilities in civilian supply — offering equipment for crisis and emergency preparedness as well as security products, all accompanied by expert advice. These retailers possess decades of experience in handling sensitive goods, technical equipment and responsible customer interaction. Their expertise makes them ideal points of contact for people seeking to prepare for extraordinary challenges.

Crisis preparedness is in good hands within the specialized trade — and the hunting and shooting sports retail sector has already provided remarkable support to the public in this regard. It is precisely this combination of know?how, quality and responsibility that makes IWA OutdoorClassics such a unique platform. Here, specialist retailers, industry leaders and experts come together to discuss solutions that are highly relevant not only for specialized sectors, but also for the overall security and preparedness capabilities of our society.

IWA demonstrates one thing clearly: we have a strong and capable specialist retail structure — and retailers who are ideally positioned to meet the growing demands associated with crisis prevention and preparedness equipment.”

Save the Date: Bavarian Minister of the Interior Joachim Herrmann on the SHOOTING EXPERTS’ Stage

In his keynote on Saturday at 11:40 a.m., Bavarian Minister of the Interior Joachim Herrmann will address current developments in the areas of civilian security and crisis preparedness. He will place a particular focus on the role of specialized retailers. His contribution adds a clear political perspective and strengthens the professional dialogue at IWA.

IWA Vision: Expertise for Retail, Industry and Media

With this year’s IWA Vision program, the trade fair sets a strong content-focused highlight, offering visitors in depth insights into risk scenarios, new business models and strategic product decisions.

1. Vision Keynote: A Possible Blackout – Causes and Consequences

What happens if a large-scale power outage hits Europe?

The keynote by international blackout and crisis preparedness expert Herbert Saurugg examines the causes, systemic vulnerabilities and societal impacts of a blackout—an issue that has gained urgency due to real incidents and the changing security environment.

2. Expert Panel: Strategic Product Selection from Survival to Crisis Preparedness

In the subsequent expert panel featuring Herbert Saurugg, crisis retailer Florian Würtenberger, Thomas Gessler (ÜberlebensHeld), survival expert Martin Linke, and Johannes Kouba (Critical Knowledge – Medical Training Solution), retailers receive concrete guidance on which product groups will become increasingly important—ranging from energy management and emergency power to first-aid equipment and communication tools that remain functional without infrastructure.

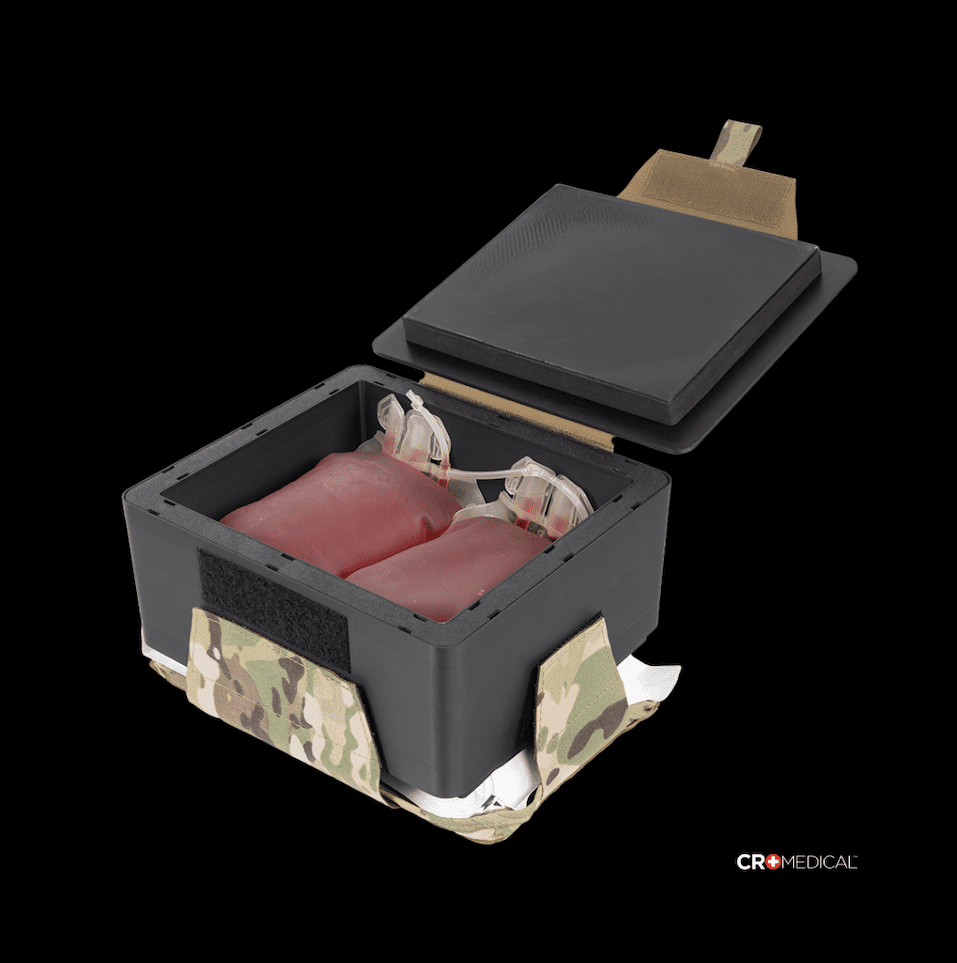

Another highlight of the exhibition is the IWA Vision Area, where manufacturers present their crisis-relevant products and solutions—bringing the thematic focus directly to the product level. Located right behind the SHOOTING EXPERTS’ Stage, the area offers retailers a compact overview of practical approaches, equipment and services that are becoming ever more important in the field of crisis preparedness.

Critical Knowledge – Knowledge transfer & training for crisis competence

Überlebensheld – Online retailer offering products and equipment for crisis preparedness

Sandberg (A&P) – Equipment solutions for emergency and preparedness concepts

Wash Innovation (A&P) – Water management and hygiene solutions for challenging operational scenarios

The IWA Vision Area combines information, inspiration and tangible product impulses—directly accessible to retailers looking to future proof their assortment.

About IWA OutdoorClassics

From 26 February to 1 March 2026, IWA OutdoorClassics will take place in Nuremberg – the leading B2B platform for the hunting and shooting sports industry. The trade fair showcases a wide range of products: from hunting, sport and airsoft firearms to ammunition, optics and knives, as well as high quality apparel, outdoor equipment and tactical gear.

With exhibitors and visitors from more than 120 countries, the event creates a unique international network for decision-makers, manufacturers and specialist retailers. Through personal exchange and targeted networking, valuable connections are formed that shape the market of tomorrow.

IWA OutdoorClassics remains exclusively reserved for trade visitors, ensuring a qualified audience actively seeking new business opportunities. More than 1,000 exhibitors are expected for IWA OutdoorClassics 2026.