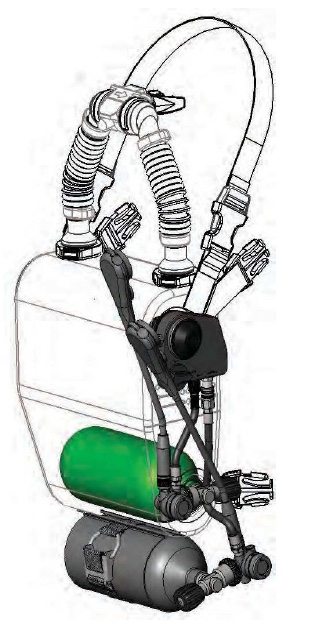

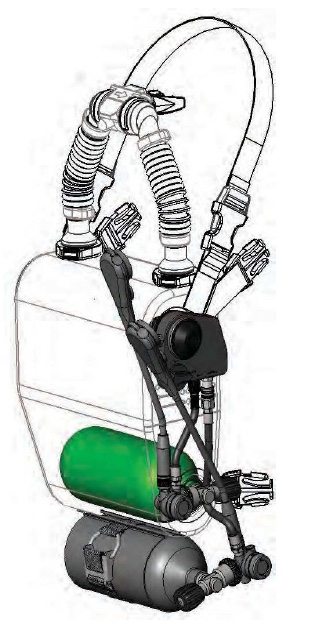

OT&E of Incursion CMR SCR with Apollo BioMask FFM and Patriot JetBootsIn use with a number of countries naval Special Forces and undergoing Test & Evaluation globally with Tier 1 units. The Open Safety Incursion CMR is a Compact Military Rebreather (CMR) that exceeds all NATO, CE and NEDU performance benchmarks and enables a wide range of missions with a single unit system: as either an O2 CCR, SCR, O2+SCR Switchable unit, Front or Back mount. Its professionally engineered clean sheet design, offering the lowest documented rebreather Work of Breathing (WOB) and long scrubber duration. This enables operators to do the same work, with less effort expended, and provides substantial OH&S benefits: inclusive mitigation of caustic cocktail risk to operators through use of American manufactured 2.2kg 5” solid state Micropore ExtendAir® CO2 technology. Enabling the unique ability to also recover the loop from flood; whilst submerged. Of course, the Incursion CMR can also be operated with 2.6kg of conventional granular absorbent and achieve the same submerged duration.

Incursion CMR O2/SCR Switch for Combat Swimming, VSW MCM or SDV ops.Features include:

• State of the art military rebreather supporting O2-CCR and SCR operating modes, both dedicated and underwater switchable. Fail-safe gas switch. Offboard SDV or EBS supplied gas whip OSEL lockable Quick-Connect compatible.

• Front or back-mount, with the same unit; compatible with diveable armour vests incorporating front, back and side plates.

• CE, NORSOK and NEDU standards compliant & certified.

• Functional Safety audited and certified to EN61508 SIL 3: with full disclosure of safety case, all test data, FMECA, HAZOPs etc.

• Rugged with exceptional availability, backed by lifetime warranty on design, parts, materials and safety – significantly reducing whole of life cycle costs to operate.

-Low maintenance, with all servicing and repairs able to be performed in-country: technician courses available.

-Includes a unique whole of life safety warranty where if the Functional Safety performance of the Incursion CMR is found to be lacking or can be improved upon; Open Safety will re-engineer the required component and supply it at their cost.

• Light: 10.3kg to 17.4kg depending on configuration, ready to dive including trim weights, scrubber and gas.

• Compact semi-rigid satchel style (35 x 41 x 16cm) including integral oxygen cylinder

-Non-mag 2L 300bar 904L SS carbon wrapped cylinders; avionic (vacuum) tested for HALO use

• Internal protected counterlungs for HALO deployment or high waterflow DPV use

• Flood tolerant and uniquely flood recoverable whilst dived

• 4+ hour scrubber duration, >6 hour gas duration (CCR/SCR modes)

• Rated for use from 0m through to 100m

• Lowest Work of Breathing in industry at

-0.35 J/L at 10m on Oxygen, 62.5 lpm RMV,

-0.6 J/L at 40m on Air, 40 lpm RMV,

-1.44 J/L at 40msw on Air, 75lpm RMV,

-0.9 J/L at 100msw on Heliox, 75lpm RMV

• Low-Mag as standard and Non-Mag options (to NATO STANAG 2897 Class A, static and dynamic tests)

• Low acoustic signature to NATO STANAG 1158

• FFM compatible

• UW comms compatible (DSV adapter)

• Integrated Bail Out Valve for immediate Open Circuit bailout an option; Open Safety ALVBOV replaces DSV

• Proven with Naval and Special Forces around the world from arctic to tropics

• Manufactured in Scotland, United Kingdom and deliberately NOT BERRY compliant.

Open Safety Incursion CMR O2 CCR shown with PPO2 Monitoring through Open Safety HUD offering full dive data display inclusive depth, dive time, compass, decompression and PPO2.Developed out of the British and Norwegian rebreather safety initiative for commercial North Sea divers, a 200 man-year project, the Incursion UBA systems are believed to be the safest and highest performance military rebreather that can be engineered today. The Open Safety Incursion CMR is supplied with Functional Safety certification – to the Gold Standard – IEC EN 61508, and at the most onerous level (SIL3) including all mechanics, electronics and software options.

Evaluating new rebreathers can be time consuming, expensive and labour intensive. To minimise that overhead, the Incursion rebreather has been the subject of one the most stringent testing regimes ever. The Open Safety Incursion system are the only military rebreather on the market whose full test results, failure analysis, performance measurements and compliance matrices are audited and published for critique by prospective purchasers to validate their procurement requirements.

The Incursion CMR is distributed throughout South East Asia and Oceania by Apollo Military, whom are also a very successful sales agent, for a number of disparate and supporting, maritime tactical products. Apollo Military are an ISO Certified company whom have been in the industry since 1988 and are now one of the premier and most respected maritime tactical operations equipment suppliers in the South East Asian region.

Apollo Military in addition to supplying the best maritime tactical equipment that we can source for our clients; also inhouse design, test and have manufactured to our specification Australian manufactured Titanium COBRA boarding ladders and JEYCO manufactured Fast Ropes; both in service with numerous Tier 1 units globally.

Apollo Military supplied Australian manufactured JEYCO Fast Rope and Titanium COBRA boarding ladder

www.apollomilitary.com

www.facebook.com/Military.Gear.Marine

www.facebook.com/OpenSafetyEquipment