FORT GREELY, Alaska — It is vital that military equipment work wherever in the world American Soldiers need it, and extreme cold is a weather condition troops have had to contend with frequently in American history.

From Korea to Afghanistan, the lives of American Soldiers have frequently depended on properly functioning equipment in inhospitably frigid environments.

This fact led to a multiweek test of the Army’s Next Generation Squad Weapon at the U.S. Army Cold Regions Test Center at Fort Greely, Alaska early this year.

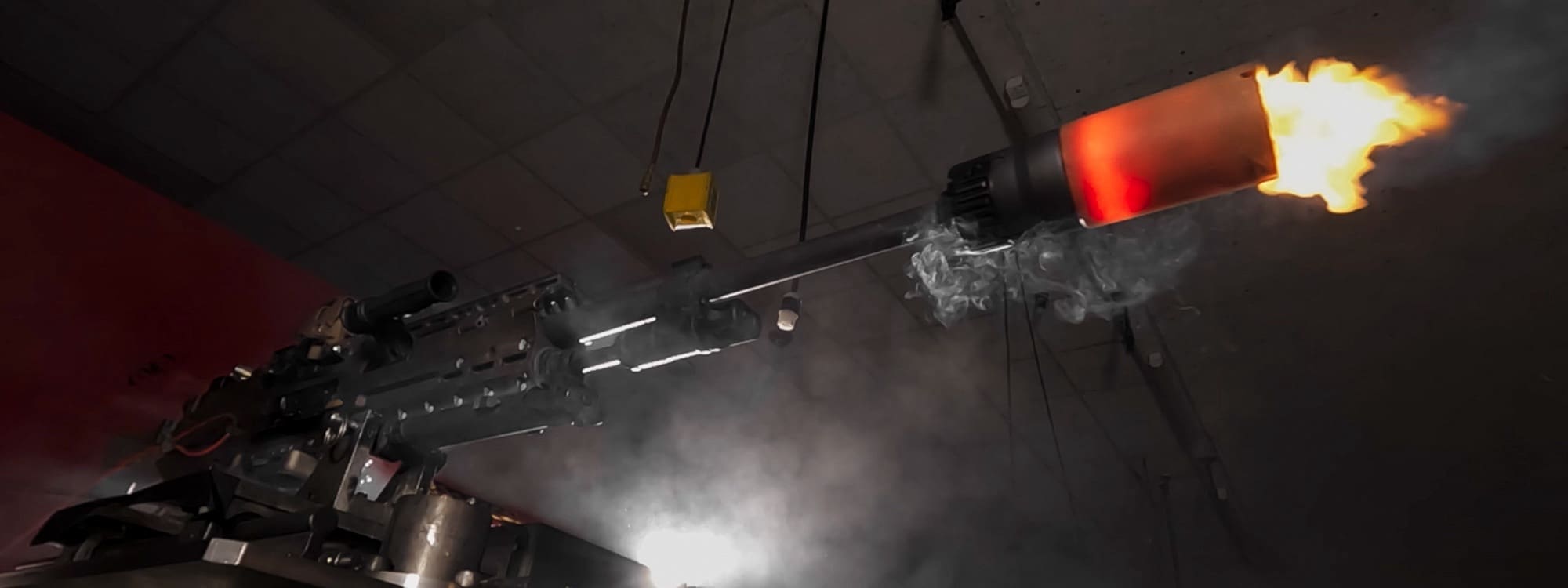

The XM7 and XM250 are successors to the M4 rifle and M249 light machine gun that American forces have used for decades. The new weapons boast improved accuracy and range, weigh less and fire with less recoil even though their 6.8-millimeter round is larger than the two legacy weapons’ 5.56 mm cartridge.

“The big idea behind this weapon is for close-combat forces,” said Steven Prewitt, test officer. “It’s a capability gap-filler for infantry and special forces, not necessarily an M4 replacement. It gives them a different tool.”

Even when outfitted with a flash suppressor, the XM7 weighs less than 10 pounds. The new weapon has a standard rifle scope with an etched reticle, but also much more.

“It has adjustable modes of operation where it can act like a red dot or close combat optic,” said Prewitt. “It also has a corrected aimpoint: it has a ballistic calculator and range finder built in, so if you range a target it takes into consideration your environmental conditions, the distance to target, and the attitude of the weapon to ensure first shot accuracy.”

Soldiers from the Army’s 11th Airborne stationed at Alaska’s Joint Base Elmendorf-Richardson supported the testing.

“We had an organic troop, which was nice,” said Isaac Howell, senior test officer. “We had the entire leadership from the company commander on down.”

The Soldiers and testers utilized the weapons in rigorous scenarios, from static and kinetic ranges at Fort Greely and Fort Wainwright to maneuver live fires and ultimately a 72-hour simulated mission across CRTC’s vast ranges. All the while, a team of 16 data collectors recorded information in the weapons’ battery life, hit-miss data on targets the Soldiers engaged, and a variety of human factors data involving utilizing the weapons in extreme cold.

“We knew it was going to be extremely fast-paced and that usually means there will be changes,” said Monica Gaschler, senior data collector. “We settled on 16 data collectors, which meant one data collector per three Soldiers. 14 went out in the field, and two stayed in house to do quality assurance on the data and write test incident reports.”

Extreme cold was a coveted commodity for this test, and the weather forecast delivered beyond the highest hopes of the testers.

“We were fortunate to have some pretty substantial cold weather for the duration of the test,” said Prewitt. “The last urban rifle marksmanship course we did was -54 degrees Fahrenheit when we started, so it was incredibly cold.”

“The Soldiers really got to experience what a long, cold day was,” added Howell. “Every day they went out one week it didn’t get above minus 20. The next week it was hovering in the minus 30 to minus 40 range all day, every day.”

The majority of data collectors who supported the test traveled from Yuma Test Center in Arizona, which like CRTC is under the command of U.S. Army Yuma Proving Ground.

“It was an endurance challenge for data collectors from the desert,” said Gaschler. “It’s rare for data collectors to be out in the field in temperatures below minus 50 degrees, but they did it without complaints. They got every bit of data, and I am so proud of every one of them.”

“We’ve got a lot of data that is informing decisions,” added Howell. “It’s very fortunate that we had a good block of cold to test this equipment, especially something as prominent as the NGSW is going to be. It has definitely been a successful test.”

By Mark Schauer