Navigating the changing currents of government contracting

>McRae Footwear learned quickly how to deliver goods to the world’s largest customer: the U.S. federal government.

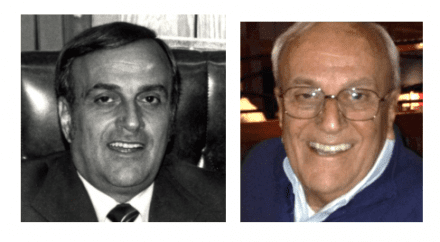

In 1969, Victor Karam, a self-described “Yankee who loves the south,” transplanted from his native New England to join McRae Industries in an executive role. A cultured Bostonian of Lebanese descent, Victor had a master’s degree in journalism but ended up in an entirely different field: women’s shoes.

During the Vietnam War, Victor was drafted into the Army and stationed at Ft. Bragg, NC. He met his future wife during that time, and they decided they wanted to live near her folks. A head hunter connected Victor with Branson McRae, founder and CEO of McRae Industries in Mount Gilead. Branson offered Victor a position as a vice president. “Branson always said he liked to hire Yankees because none of the southerners understood production,” Victor laughs.

“Salary negotiations were interesting. Branson asked me my annual salary target. I told him I expected to match my current salary, which at that time was $15,000. ‘That won’t work,’ Branson said. ‘It’ll never be approved by the board, because I only make $12,000.’”

Despite the dip in pay, Victor was intrigued by Branson’s company and accepted the job. He thought he would move on after a year or two, but ended up staying for more than 45 years, eventually becoming president of McRae Footwear. He continues to serve on the board of directors.

Becoming a preferred contractor

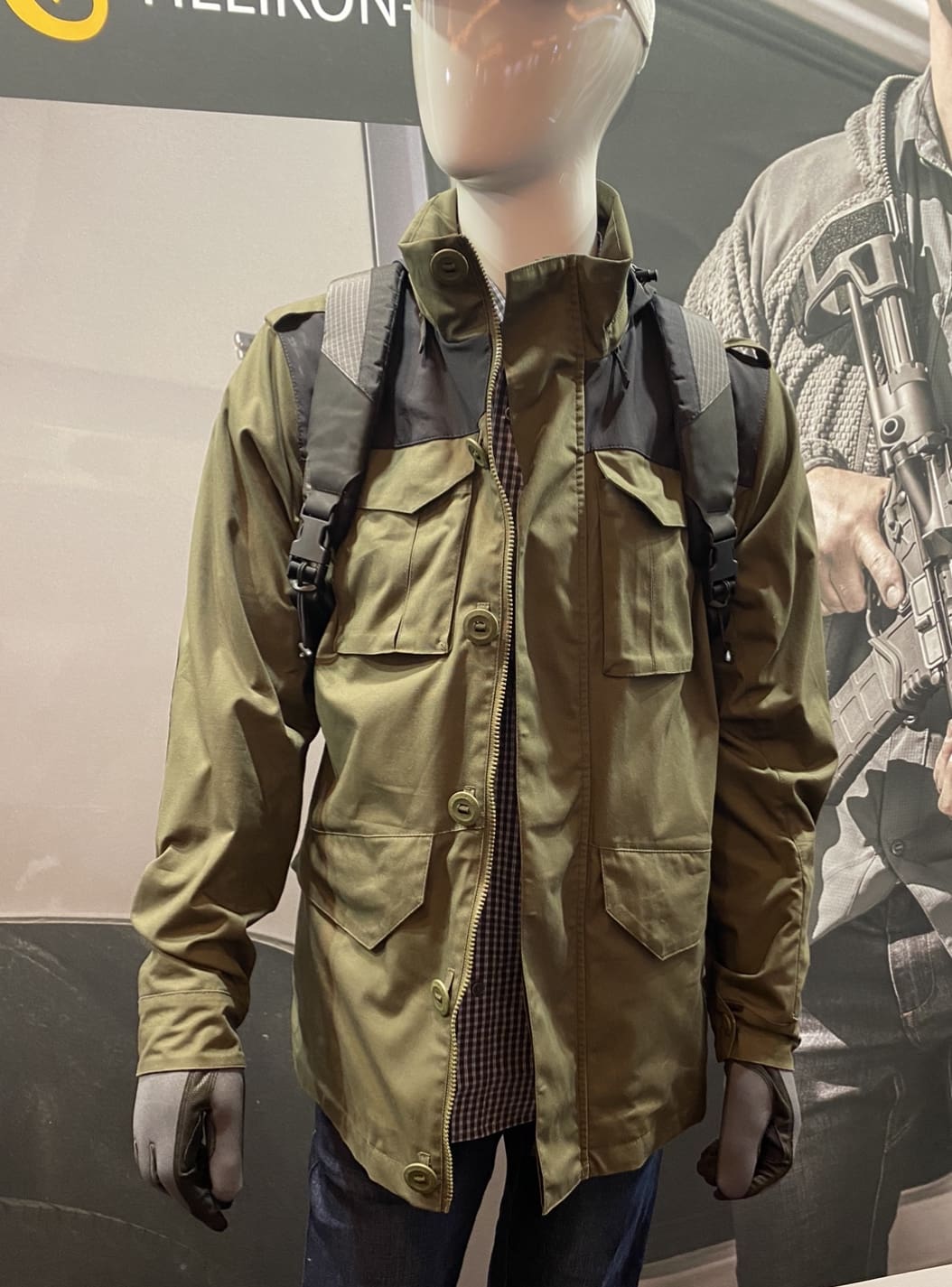

Along with its knowledge of the government’s preferred mode of boot construction – vulcanized, direct molded sole — McRae had two other distinct advantages as a contractor. With fewer than 500 employees, the company qualified as a small business. And it qualified also as having a manufacturing plant in a “labor surplus,” or high unemployment, area. The Department of Defense “set aside” contracts for small businesses, and being labor surplus gave the company a price advantage over large businesses.

Home grown: By law, in making purchases, the federal government gives preference to domestically produced and manufactured products.

To supplement its U.S. government contracts, McRae made combat boots for other nations. For 25 years, the company has been a supplier of military footwear for the government of Israel. Over the years, McRae has also provided boots for military forces in Canada, Brunei, Great Britain, and Saudi Arabia.

“The federal government has consistently praised us for our high-quality products.”

– Victor Karam, director, McRae Industries

Following government specs

“At the time, the design of McRae’s military boots was dictated by the government,” Victor says. “We didn’t have a lot of input. We didn’t have a shoe manufacturers association. The government gave us the patterns and told us how to make the boots. Requirements were so rigid that a slight defect could cause the military to reject an entire production lot of boots.”

Talking though the specs: Being a government contractor required frequent trips to the Defense Personnel Support Center in Philadelphia.

“Branson made it clear that every government specification was to be met. ‘The longer you work here with me, whether you agree or disagree with the specs, you follow them,’ he said. ‘If you see something that needs to be changed, go through the proper channels to get it changed. If you can’t, don’t change it.’’

Specifications were – and still are – exacting and relentless, from cure time for rubber to the boot’s ability to withstand pressure. Government protocols are strictly enforced with McRae workers. Government inspectors frequently walked the floors of the McRae factory. “I don’t know that any of the inspectors that came through had shoe knowledge,” Victor says. “We had to teach them.”

If Branson felt a spec were wrong, however, he was not afraid to question it – through established government protocols. That involved meeting with federal representatives in Philadelphia to clarify requirements or, in one instance, challenge a boot recall.

Victor tells the story of an inspector sent in from Charlotte, NC. “This inspector tested and rejected a production lot of boots where a wrinkle was detected. But the regulations specified boots should be rejected if a horizontal wrinkle were found when tested between both thumbs. The wrinkle detected in this lot was vertical. We showed the quality controller in Philadelphia, and we won our case.”

Looking to the future

Today, about 90 percent of McRae’s military boot business is tied to government contracts. The company also makes commercial versions of its boots.

“Staying flexible and expecting the unexpected is all part of succeeding as a government contractor,” Victor says. “Demand may fluctuate, but our purpose never waivers: To help our troops fulfill their missions though durable and reliable footwear.”

Adding on: As boot orders from the U.S. government accelerated, McRae over time added on a second 100,000-square-foot facility in Troy, NC. This facility houses the company’s direct-attach injection-mold equipment for manufacturing current-spec military boots, along with lasting, finishing, warehousing, and shipping functions.