Military leaders are asking their components to become more agile.

What does that mean? To be agile means adopting and accepting the agile principles, moving away from a top-down hierarchy filled with bureaucracy and individual silos, Agile promotes a ‘guiding’ leadership model surrounded by teams that are flexible and accountable.

Where did Agile come from? Agile was born out of necessity in software engineering to provide faster updates and build upon user feedback. Prior to the modern agile movement, development teams would identify the problem, create a solution, develop a product, then bring it to market, all without extensively engaging the customer. This is known as the ‘waterfall approach’. This method has proven to be slow, cumbersome, and often times, brings a product to market which does not meet the true need of the customer. In early 2000, software developers met to discuss their challenges, and later in 2001, developed what is known today as the ‘Agile Manifesto’. The key values of which being: people over process, working product over comprehensive documentation, end user collaboration over contracts, and responding to change over following a plan. Agile is now in use by every Fortune 500 company and is utilized by more than 97% of mid-market commercial companies worldwide. Adopters of Platinum Edge’s suite of services have enjoyed a 30-40% increase in time to market with a cost savings from 30-70%. Although the original idea was for use in the technology world, the values and principles remain true for any type of program management.

The U.S. military has a long history of being the focal point of excellence when it comes to planning and execution. Utilizing the JOPES and MDMP process is a long-proven method of planning and conducting military operations. As the Military shifts to a more business-like model, there is a need to adopt the proven agile approaches to accomplish our goals.

So, how and where does the Military adopt Agile? Like many businesses and organizations, the Military has to be open to change, both in culture and structure. In military planning, there is a hierarchy and clear chain of command. With Agile however, you must allow for the team to take ownership while leaders should act as a guide. Think in the terms of staff functions from company level, to corps, and above. The staff directorates from your S-1’s, G-2’s, J-3’s, etc., work within the confines of their ‘stove pipes’ and report to a Chief of Staff or Commander on individual efforts. In an organization using Agile, you create cross-functional teams based on products. These teams are developed based on the talent needed to complete the end product, not just with whoever is available, i.e. ‘people over process’. This lightweight team concentrates on a goal while incrementally chopping away at the deliverables. The team holds each other accountable along the way and communicates as much as possible in order to facilitate success. This model allows for self-correction and keeps the ‘customer’ involved along the way.

How does an individual, a team, a unit become more Agile? To become agile is not just a declaration or a command. To be agile means a formal adoption of principles while putting faith in the system and processes. Training is available from the basics of agile, Certified Scrum Masters of multiple levels, as well as coaching, mentoring, objective audits, and more. Each of the courses are credentialed, and are free to the soldier via IgnitED (the Army’s new Credentialing Assistance platform). Being credentialed in agile frameworks provide opportunities for future employment as well as tools for the current scope of work. Companies like Platinum Edge provide these opportunities both virtually as well as in-person and can scale to meet the need of the individual, the team, or the unit.

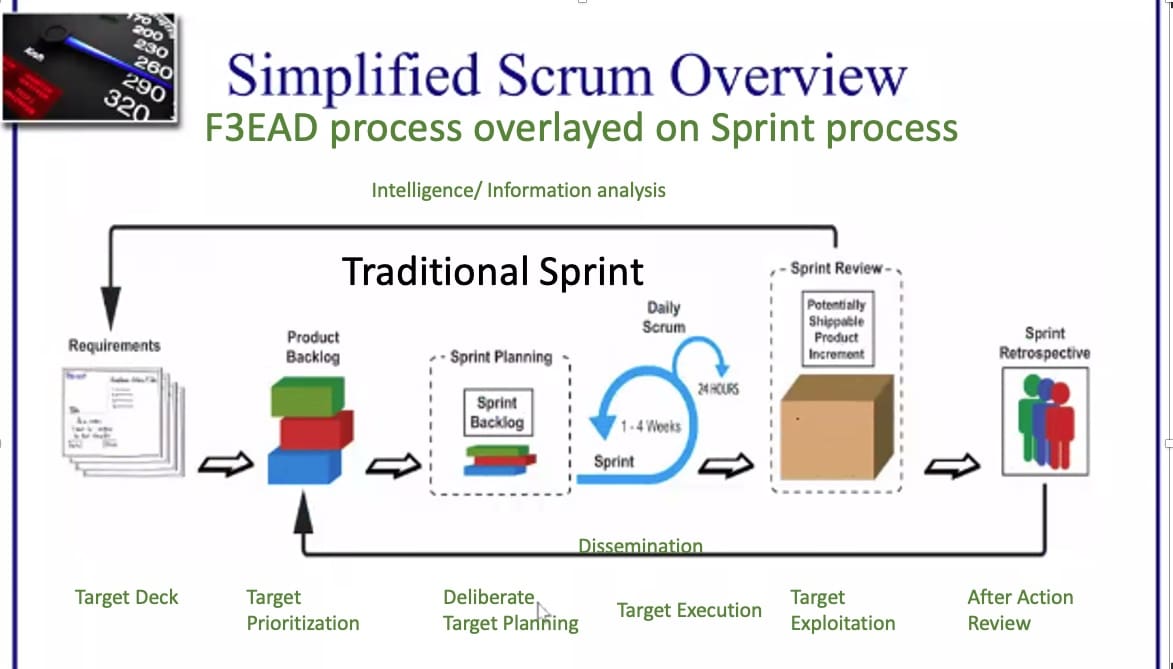

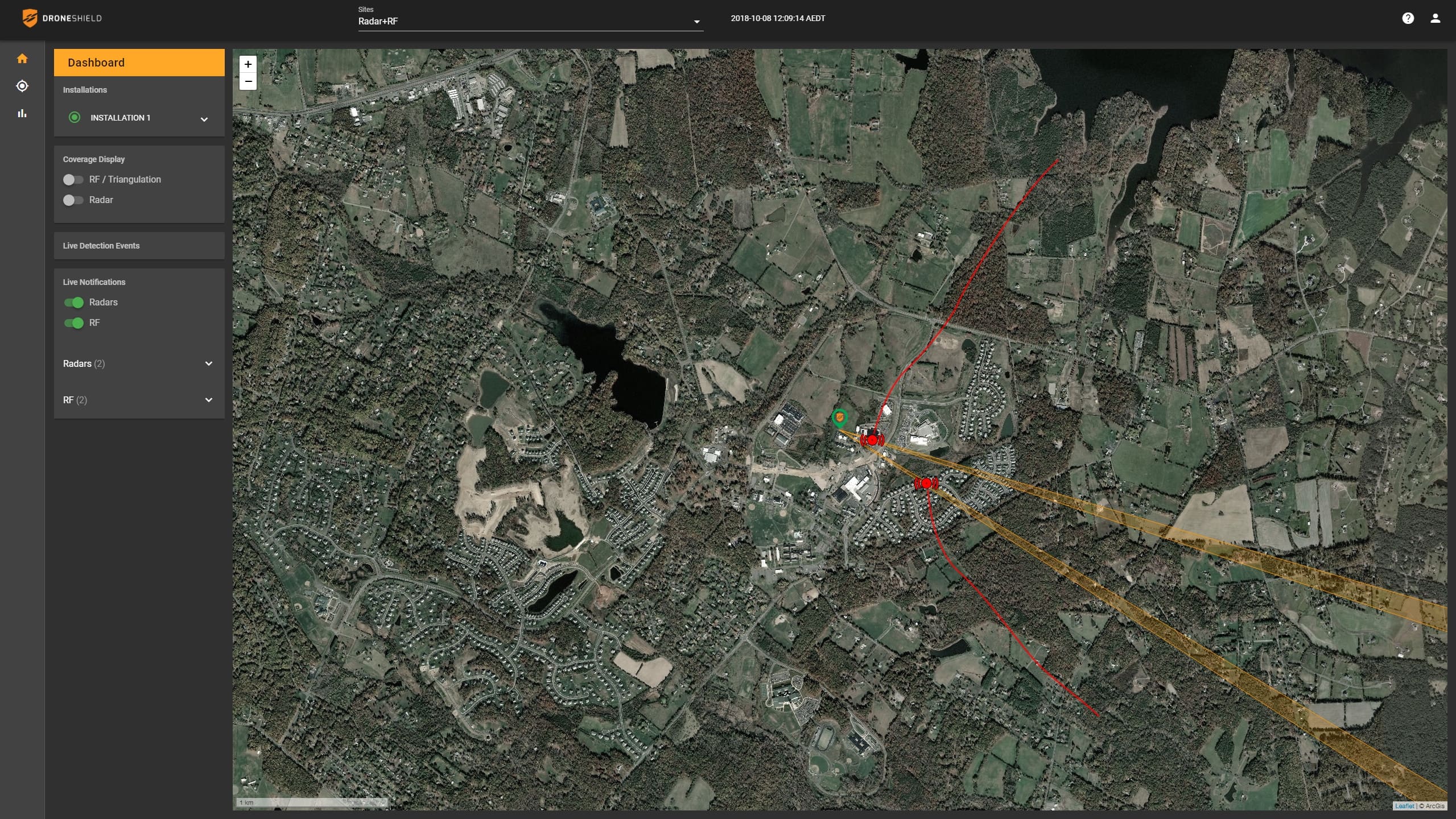

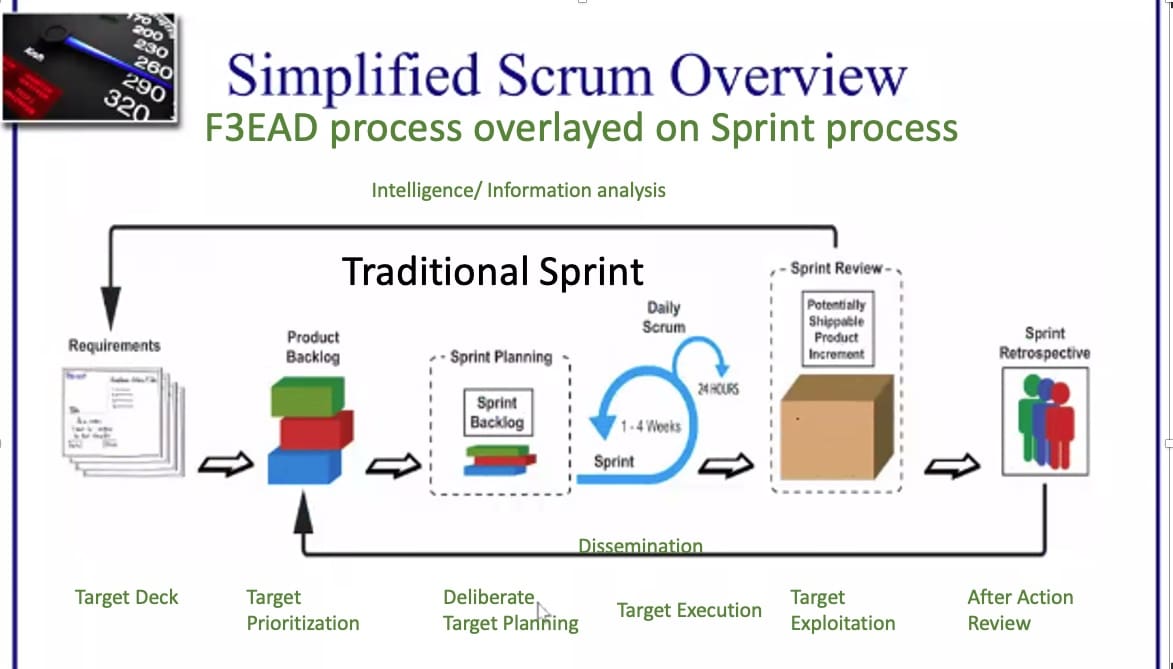

SCRUM, it’s not a rugby maneuver… so, what is it? scrum is a transparency framework that helps us identify what is working in reality. It is a self-correcting model in which, even if you are wrong in the beginning, you can be right in the end because scrum gives you multiple opportunities to correct course toward the target. Tactically flexible yet strategically focused, your next move changes but your target is stable. It is also a structured learning cycle that allows you to adapt and change based off of experience. At the core of a scrum is the ‘sprint’. A sprint is the activity that drives the process. The sprint is a time-determined activity in which the major product development tasks are completed. At the end of the sprint, the scrum team conducts a ‘retrospective’ to determine what worked, what didn’t, what can move forward, and what can wait. Every level of a military unit can utilize the scrum framework, whether it’s project management, or conducting operations. It is flexible and adaptable to all situations. Many military leaders are familiar with the F3EAD process, scrum is similar however it does take training to practice scrum correctly. Having a coach or a Certified Scrum Master ensures you are playing correctly.

How does being a ‘Certified Scrum Master’ (CSM) help me?

The Scrum Master is a member of the scrum team, who is charged with making sure everyone on the team is playing scrum correctly. Think of them as a referee in a sport; an objective outside influencer that ensures the game is played correctly. The Scrum Master is a majorly critical piece in the scrum team, and the position is not to be taken lightly nor ignored. If the military is to adopt agile, identification of the right talent and promoting this position is of the utmost importance. By choosing to be a Scrum Master, you are joining a small community of individuals whose expertise can be utilized no matter the type of work. To be an objective outsider means you can walk into any type of business or organization and play scrum, no matter the type of product. As a CSM, you can move easily throughout any organization providing great value, both in the military, and post-career in any one of the 40,000 businesses currently seeking CSMs (most positions offer $100,000/ year).

How can I become a ‘Certified Scrum Master’? Becoming a CSM is easy. Platinum Edge has a 2-day (in-person) or 4-day (virtual) Certified Scrum Master course, during which you will learn the basics of being a CSM. Similar to gaining rank in the military, there are multiple levels of a CSM and you must meet certain training and experience quotas prior to advancing. The more you advance, the better you are, and the more valuable an asset you are to the team. Credentialing Assistance allows for a service member to obtain their CSM credentials as well as follow on courses. Each service member (Enlisted/Warrant) is allowed $4000.00 per year in assistance, which is more than enough to obtain their CSM, as well as propel through the levels during their career. As of August 15th, the Army has transitioned to IgnitED for all credentialing opportunities.

What else should I know? Before you dive in, I encourage you to discover more about Agile and SCRUM. The first recommended read is the Agile Manifesto. This lays out the reasoning and principles of agile and is the basis for all agile techniques. Next, the Scrum Guide, gives you an overview of the terms, definitions, positions, and events of SCRUM. The Agile Method on LinchpinSEO is a great article on traditional vs. Agile approach. You can also get deep into the weeds with the SCRUM for Dummies guide, written by Mark Layton.

Why Platinum Edge? I have mentioned Platinum Edge and Mark Layton throughout this article and for good reason. Mark is the founder of Platinum Edge and is the world’s foremost expert on transforming organizations to the agile methodology. Mark, a veteran of the US Air Force, also holds a secret security clearance and is a published author on the subject of scrum and agile. The 1st Special Warfare Training Group at the US Army Special Warfare Center and School has placed their trust in Platinum Edge to provide CSM training to their instructor corps for individual professional development, as well as to begin their change in culture. If you are an instructor at SWCS or assigned to USASOC at Fort Bragg, reach out to 1st SWTG (Project JANUS) to learn more about your training opportunities. For all others interested in obtaining credentials or information on credentialing assistance, visit your local Education center. As for everyone else, feel free to contact Platinum Edge for more information.

Tom Kerr, a retired Special Forces NCO who attended the Certified Scrum Master Course during his transition from service and now utilizes the agile methodology and practices scrum in his daily program management duties at the Strategic Advisory “Firm”, Armor Corps.