Coupon Code: LABORDAY20

20% OFF Through 9/8

Tectonica is pleased to announce that it has secured a major contract with Rheinmetall Defence Australia for the manufacture of sophisticated camera technology for Army’s new Boxer 8×8 Combat Reconnaissance Vehicles (CRVs) delivered under the Commonwealth of Australia’s Mounted Combat Reconnaissance Capability project (LAND 400 Phase 2).

Under this contract, Tectonica will deliver its ALTERA Local Situation Awareness System (LSAS) on all BOXER 8×8 CRVs to be manufactured at Rheinmetall’s Military Vehicle Centre of Excellence (MILVEHCOE) from 2021.

The LSAS uses visual technologies to provide vehicle crews and operators with improved situational awareness by enabling them to see their surrounding environment by day and by night while remaining protected under armour.

This is the second LAND 400 Phase 2 contract awarded to Tectonica, following on from the September 2019 award to install LSAS on vehicles on the early capability delivery fleet of BOXER 8×8 CRVs currently being built in Europe.

Contributing to the Australian Government’s focus on becoming one of the world’s top 10 defence exporters, Tectonica has also secured a significant export contract to design, develop, manufacture, and export its BANTAM data and power distribution system to the German Army under a contract with Rheinmetall Electronics. The technology will be deployed through the Bundeswehr’s Very High Readiness Joint Task Force (VJTF) and is fitted to every soldier wearing a computerised backpack.

Developed in Australia, with the support of the Defence Science Technology and Australian Defence Force to reduce the bulk and weight carried by soldiers, the BANTAM power system distributes power from a central source and gives the dismounted soldier the freedom to concentrate on their mission, confident that the modular high-tech power management device will last the duration of their mission.

The total value of these contracts awarded to Tectonica is over $25 million.

Tectonica’s Managing Director, David Levy said, “Our partnership with Rheinmetall is a great example of industry working together to strengthen the Australian Defence Force and build sovereign industry capability”.

Imminent Threat Solutions is proud to release the ITS Trauma Kit™ in our proprietary Tru-Flex™ gusseted stand-up bag, in addition to our industry leading TruFlex™ vacuum-sealed trauma kit. The durable heat-sealed closure ensures that the components are easily accessible, tamper-proof and protected from water, dust, or other contaminants. TruFlex™ also makes the kits easier to open using the visible red-triangle corner tear notches. Once ripped open, the exposed zip-closure can reseal and protect any unused components.

As a limited-time introductory offer, get an ITS Medical Edition Nylon Zip Bag FREE when you purchase an ITS Trauma Kit™. Simply add BOTH the ITS Trauma Kit™ AND ITS Medical Edition Zip Bag to your cart to see the discount applied automatically.

Some might debate the expense or need for a trauma kit, but rest assured, what you’re buying at ITS is 10+ years of continuous product improvement and knowledge in sourcing the very best components. Remember, you might not be the one using your kit; it could be a better-trained responder without necessary aid supplies.

WESTFIELD, Massachusetts – September 3, 2020 – Savage Arms is now hiring for multiple positions at its Massachusetts headquarters. The company is currently searching for qualified applicants to join the Savage team in engineering, sales support, and operations.

“2020 continues to be a strong year for Savage and we’re excited to be adding to our family,” Chris Bezzina, COO of Savage Arms said. “Savage continues to lead the industry in innovative new products that are designed and built here in North America by very talented people that are proud to be in this industry and passionate about our products.”

At the factory in Westfield, Massachusetts, Savage continues a tradition that began more than 125 years ago. Hunters, competitors, marksmen and plinkers all trust the Savage and Stevens brands for our proven accuracy and performance. Savage firearms put rounds on target and meat on the table. Now, as the company settles into a new period of self-governance, Savage continues to build out its catalog of innovative new firearms that are not only designed around safety, but are also able to improve the user’s experience through enhanced fit, versatility, and functionality.

AVAILABLE POSITIONS:

• Sales Support

• Engineering

• Operations

For more information about the available positions, or to apply: click here.

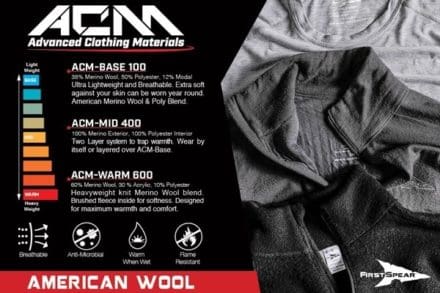

Fall is knocking at the door and FirstSpear is giving us a look at an extremely popular garment from their all American merino wool apparel line up, the Hooded Field Shirt. This garment is generously cut with an oversized hood with absolutely no hardware making for an incredibly comfortable and highly functional base layer or perfect stand alone top when temperatures are fluctuating.

Built from FirstSpear’s proprietary USA Wool packages the Hooded Field Shirt uses the lightest weight weight package, ACM BASE 100 which is not just extremely light, soft, and breathable but it features all the naturally occurring performance benefits of merino wool including antimicrobial, FR resistance, and warm when wet.

Available now in Sand, Charcoal, Heather Grey, Commando, and Black. FirstSpear American Wool is 100% Berry Compliant – Made in the USA with USA materials.

www.first-spear.com/hooded-field-shirt

ABERDEEN PROVING GROUND, Md. (Aug. 25, 2020) — Army Futures Command (AFC) is assessing commercial communications technologies that will be integrated in the next generation of command posts.

The Command, Control, Communications, Computers, Cyber, Intelligence, Surveillance and Reconnaissance (C5ISR) Center — a component of AFC’s Combat Capabilities Development Command — is leading this effort during the Network Modernization Experiment 2020 (NetModX 20), which began last month and will run through Oct. 2 at Joint Base McGuire-Dix-Lakehurst, New Jersey.

Scientists and engineers, accompanied by Soldiers serving as advisers, are conducting experiments using millimeter wave technologies. Their intent is to adapt commercially available solutions that will reduce the enemy’s ability to detect the communications systems’ “noise,” or tell-tale electronic signature; withstand the adversaries jamming attempts; and make it easier to quickly relocate the command post — staying one step ahead of the enemy.

“The work to identify, test and militarize robust communications is critical for command post dispersion and mobility,” said J. Tyler Barton, C5ISR’s lead for Command Post Concepts. “Our goal is to help the Army determine which system specifications are needed to provide an effective operational capability so they can decide which to procure for upcoming command post integrated infrastructure (CPI2) experimentation and operational assessments.”

The initiative supports the C5ISR Center’s technology transition partner, the Army’s Product Manager CPI2, and contributes to the Army’s long-term objectives to design, test and field a cohesive command post structure with a reduced footprint that will replace large, tent-based command posts.

NetModX 20 CPI2 experiments will build on laboratory experiments conducted at Aberdeen Proving Ground, Maryland, earlier this year. Researchers will learn more about the systems’ ability to communicate effectively with a low probability of intercept and detection. They will also examine whether a system can avoid disruption and jamming or identification and targeting from near-peer threats.

According to Joseph Saldiveri, interim project lead for NetModX 20, this type of field-based experimentation can change the trajectory of a project’s development and lead to a “more robust, flexible and relevant solution when the project is ready for operational testing.”

“It’s important to bring technologies out of the lab and into the field environment … because experiments in the field often yield different results than experienced in the lab,” he said.

Paul Tardy, PdM CPI2’s futures and lead systems engineer, also spoke about the significance of the experimentation environment.

“Iterative Soldier touch points, such as NetModX, are essential as the Army matures technologies and gets highly relevant new and enhanced capabilities procured and into the hands of the Soldier,” he said.

Following NetModX, the tested systems will transition to the Army’s Project Manager Tactical Network, which will supply a complete wireless network capability and integrate the systems into CPI2.

“These technologies will bridge the gap between commercial off-the-shelf technology and longer-range science and technology project areas to leverage for near-term quick wins for the Soldier,” Tardy said.

Barton and Tardy encourage industry and government representatives interested in aligning their command post efforts with Army’s to participate in the Army Network Capability Set 23 technical exchange meeting Sept. 2. Additional information about the event is available at go.usa.gov/xG3Kk under opportunity listing “W15P7T-20-R-TEM5.”

Story by Dan Lafontaine, C5ISR Center Public Affairs

Photos by Jasmyne Douglas, C5ISR Center Public Affairs