RYP (Robert Young Pelton) and William Harsey Jr. have collaborated on a knife — a knife designed as a tribute to the legendary Billy Waugh.

“Why the hell would anyone want my name on their knife?” Waugh asked when they approached him with the idea.

Journalist-Adventurer RYP first met Waugh, a retired Special Forces soldier turned CIA paramilitary, at a Texas Waffle House for an interview. One of the things Pelton, a knife designer, wanted to know was what sort of hardware Billy carried on his missions behind enemy lines during the Vietnam War. Billy remembers his favorite tools being the local (machete-like) parang and the machine-stamped Demo knife issued to soldiers.

RYP offered to design a series of knives that would integrate Waugh’s hard-earned ideas into a reimagining of tactical blades.

That’s when Billy scoffed and gave his reply.

Here’s more from the release:

Pelton disobeyed orders and recruited legendary Special Forces knife designer and friend William Harsey Jr to make Billy proud. Together they fine-tuned collaborated on a design only a warrior of Billy Waugh’s level could sign off on.

The design was inspired by the standard issue multi-purpose knife Waugh remembers from his Vietnam days. The DEMO is not the result of the lowest bidder. The Billy Waugh version is not only a knife fitting of the special operator, but an homage to toughness, and performance under fire. The DEMO features a balanced three dimensional Titanium alloy body with a retro diamond pattern and vintage finish. The four inch flat grind M390 blade is on bearings, with flipper, glass breaker screw, and an Awl on bronze washers. The knife comes with a replacement flat head screw. The deep pocket combat clip is engraved with Billy Waugh’s signature. The blade is laser engraved with William Harsey’s signature.

Limited quantities of the Billy Waugh edition will be created with the unsigned DEMO version going into production runs later this year.

BILLY WAUGH: AN ARMY SPECIAL FORCES AND CIA LEGEND

Billy Waugh at age 91 has a military and intelligence career that can only qualify as legendary. Prevented from enlisting for WW2 because of his age, Billy signed up for the newly created Special Forces – choosing the most dangerous tasks our nation demanded. Billy is the recipient of eight Purple Hearts and has a lifetime of service to America. Billy Waugh continued his Special Forces career all the way to the opening months of the war in Afghanistan. His 20 years to the CIA post-retirement made Billy officially the oldest serving CIA contractor in history. Billy’s book “Hunting the Jackal” covers his time tracking Carlos the Jackal and Bin Laden, and “Isaac Camacho An American Hero” is his homage to a fellow Green Beret.

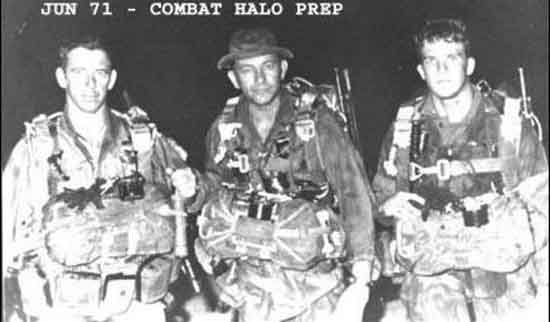

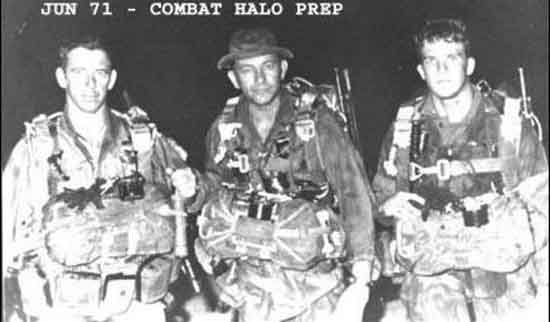

Billy Waugh prepping for a HALO jump in the Republic of Vietnam. Waugh was medically retired, went to work for the CIA, and remained in service ever since. He spent his 70th birthday on a mountainside in Afghanistan during the opening days of OEF.

WILLIAM HARSEY JR

To honor a legend of Billy Waugh’s background, Pelton teamed up with award winning designer William Harsey Jr. Harsey grew up as a logger in the Pacific Northwest but managed to get a degree in fine design. He put his elegant artwork and knowledge of the craft to design knives, and the rest is history. Harsey is the creator of the Applegate Fairbairn Combat Folder and the equally famous “Yarborough” design, which is issued to each Special Forces graduate. Harsey’s designs can be purchased from Gerber, Spartan Blades and Chris Reeves Knives.

ROBERT YOUNG PELTON

Robert Young Pelton is not only an award winning knife designer but best known for his lifetime of documenting war zones on film, and in his books. His time with SF ODA 595 or the “Horse Soldiers” in Afghanistan during the winter of 2001, led to the unit adopting his patch. Billy Waugh is featured in Licensed to Kill — Hired Guns in the War on Terror Pelton’s best seller on contractors, paramilitaries and mercenaries. Waugh and Pelton have shared some of the same wars and hit it off. They have been friends ever since. Billy has been approached numerous times with the idea to make a Billy Waugh specific model. Billy has graciously refused – until now.

RYP.Design is a new venture in which Pelton will partner with designers and legends to create unique products ranging from books to graphic novels to knives to survival designs. The initial limited edition DEMO is only offered for sale through two websites: www.ryp.design and exclusive RYP Design dealer, Straack –www.straack.com.

RYP DESIGN PRESENTS THE BILLY WAUGH DEMO LIMITED EDITION

KNIFE SPECIFICATIONS AND PRICING

Weight: 6.80 oz/ 193g

Overall Length: 9.13″/ 232mm

Blade Length: 3.78″/ 96mm

Blade Steel: M390

Rockwell Hardness: 60

Blade Coating: Matte black PVD, then stonewashed

Blade Thickness: .16″/ 4mm

Handle Material: 3D Titanium