Now in its second year, Operator Expo has done a great job of bringing Canada’s tactical companies together.

Now in its second year, Operator Expo has done a great job of bringing Canada’s tactical companies together.

GM Defense is expanding its global strategy to Canada, leveraging the existing relationships of GM Canada along with the advanced technologies and capabilities of its parent company, General Motors, with the aim of delivering efficient and innovative solutions to international military, security and government customers.

Fully aligned with its parent company’s vision for an all-electric future, GM Defense will leverage commercial battery electric technology and recent EV manufacturing investments to help defence and government customers transition to a more electric, autonomous and connected future. GM recently announced $2B to transform both Oshawa Assembly and CAMI Assembly plant, which will become Canada’s first full-scale EV manufacturing plant. The company also announced a partnership with POSCO to build a new $500 million facility in Quebec that will process Cathode Active Materials for EV batteries. GM Defense will leverage these investments to deliver customized solutions based on commercial derivatives that enhance capabilities for defence and government customers in Canada and overseas.

Safran Optics 1 supports non-profit organizations which seek to improve the lives of veterans and military families. Most recently, Optics 1 partnered with the Sterling Promise Foundation to host their first-ever fundraiser during Special Operations Forces Industry Conference (SOFIC) 2022. With the help of industry sponsors, financial donations and a silent auction, the foundation received $43,500 to support their mission.

The Sterling Promise Foundation exists to honor the life of Staff Sergeant Scott Sterling, who passed away in April 2021 after a heroic battle with colorectal cancer. Scott served in the 75th Ranger Regimental Reconnaissance Detachment and 1st Special Forces Operational Detachment-Delta. The foundation is dedicated to ensuring that veterans are able to live long, healthy, fulfilling lives following their careers in the US Army Special Operations, through early cancer screenings and awareness campaigns.

With financial assistance, the foundation can focus on early detection cancer screenings and augment related medical benefits for special forces members and veterans before cancer takes another soldier. Some of their ongoing initiatives include:

• Partnership with Cologuard® to promote early screenings for colorectal cancer

• Free colorectal screenings for veterans, regardless of age, whose insurance benefits do not cover

• Awareness campaign targeting the special operations community promoting all GI cancer screenings

Optics 1 was honored to host this event to raise funds and awareness for the well-being of our nation’s veterans, while celebrating the life of Scott Sterling, a cherished industry friend.

REDSTONE ARSENAL, Ala. — Anyone can submit a problem to the Army Software Factory.

To be clear, that is not just anyone at the factory, or in the formation, or anyone of a certain rank or office. Anyone in the U.S. Army can submit a problem to the Army Software Factory. It is an innovative concept but one that fulfills the promise of Army Futures Command.

When AFC was stood up in 2018, it was understood that it would not be business as usual. And when AFC opened the Army Software Factory in 2021, it was making good on that promise. The first-of-its-kind factory brings in rotating groups of Soldiers and Army civilians through a highly competitive application process and trains them in modern agile software development. Joshua Farrington of the U.S. Army Combat Capabilities Development Command Aviation & Missile Center, or AvMC, is one of those civilians chosen for a prestigious factory rotation. Farrington is currently in a three-year assignment at the factory located in Austin, Texas.

“Employees that accept a rotation with the Army Software Factory bring their unique perspectives and capabilities from their home organizations and share those ideas into our ecosystem which further widens our vision of what is possible,” said Maj. Christopher Bennett, product manager at the Army Software Factory. “In addition to building their collaboration skills, rotations of employees that come through the Software Factory will encourage innovation through context-sharing on problems and products. When more people see a greater variety of problems and pains solved by software across the Army, it helps build a repository of ideas more easily shared across teams to reference.”

The program starts with a 16-week boot camp. There are four different tracks — platform engineer, software developer, product manager and designer. Farrington is on the software development track.

When a problem is submitted, the factory has a team to vet it. They do interviews, an initial scoping, and then decide whether to accept the problem. Once a problem is accepted, the assigned team works with partners to build a web application to address the problem — providing the collaboration that Army Futures Command is striving to foster Army-wide. Currently, Farrington is working on an application that will assist the 101st Airborne Division in their air assault mission planning process.

Another innovative aspect of the factory is that it is “rank agnostic” with Soldiers solving problems for Soldiers — an experience that Farrington said has been personally beneficial.

“It has been impactful for me — working directly with a lot of Soldiers,” Farrington shared. “At AvMC, we were doing things for the Warfighter but I was not around the Warfighter. Now, here, I am on a team with three other Soldiers who have directly dealt with the problem we are trying to solve. My impact for the Warfighter feels a lot more tangible.

“I was a civilian at AvMC writing Army-related software and I just wouldn’t have the context on what the app was actually doing because I had never flown a helicopter. So a Soldier who actually understands the context of how an app is actually going to be used – it just makes it so much easier to make decisions. I think having more Soldiers writing software will be a huge asset to the Army.”

In the Army’s continuing mission to transform itself from the industrial age to the information age, the Army Software Factory is a key player in the future fight — one that will be as much in the virtual cloud as it is in the physical ones.

“One of the big purposes of the Software Factory is to increase the software that is in the Army’s technical capabilities,” Farrington said. “The talent is already there, the Software Factory is finding a way to make the most of it.”

By Katie Davis Skelley, DEVCOM Aviation & Missile Center Public Affairs

Testing and evaluation on an Aero Precision rifle was conducted by a west coast law enforcement agency. The rifle was tested to several NIJ testing procedures followed by a 10,000 round endurance test where the rifle experienced 0 operational malfunctions.

The following NIJ test procedures mentioned above were performed:

– Initial 60-round test firing

– 12hr Freezer (30-round test firing after)

– 12hr Oven (120 degrees Fahrenheit / 30-round test firing after)

– Six position drop test (5-round test firing after each drop) *Charging handle lever on the port side broke, flash hider came loose, pistol grip came loose. None of these issues impacted the functioning of the rifle and where appropriate, were re-tightened.

– Water submersion (30-round test firing after)

– Sand submersion (30-round test firing after)

– Initial zeroing w/optic and irons (T&E Optic failure during drop test which doesn’t impact the rifle test. A second T&E optic also failed. A third T&E optic was mounted during endurance firing)

– Final zeroing (3-round zeroing shots near the end of endurance testing resulted with an acceptable zero within 2.75”)

Included in the above test procedures was a 10,000-round endurance test. The rifle was first cleaned and lubricated and then was only lubricated in 1000-round intervals during the course of fire. The firing schedule for this rifle consisted of 150-180-round increments from various shooting positions and firing rates with an 8–12-minute cool down period in between cycles utilizing a 4’x4’ industrial fan. The gas rings of the rifle were replaced at 6,040 rounds and a final zeroing test was conducted at round 9,960.

The Aero Precision T&E rifle fired a total of 10,040 rounds without experiencing a single malfunction, even in extreme conditions that fall outside normal use.

To learn more about Aero Precision and to view the full product library visit www.aeroprecisionusa.com.

Expedition Grade, Field Short for All Terrains in Amphibious Ripstop Nylon

Prometheus Design Werx launches their popular Raider Field Short in TRS for Summer 2022. An expedition grade field short designed for rigorous and protracted all terrain adventures and exploration. Constructed in their 6.13oz, technical, 4-way stretch Technical Ripstop nylon with a quick-dry and DWR finish for durable wear on land or in the sea. A total of 11 pockets to stash and organize as little or as many EDC items as the user needs. Pocket Clip Docks™, quad no-twist custom made Delta-Rings for keychain-carabiner clip points, double reinforced seat, and a Hide-Away waistband pocket round out these shorts’ features. Produced with industrial grade triple needle stitching on all major seams and expertly made in California, USA.

The Raider Field Short TRS by Prometheus Design Werx will be available in Transitional Field Green, Universal Field Gray and All Terrain Brown.

The Design and R&D Team at PDW states:

“Our TRS cloth has proven to be one of our most popular fabrics or all-season wear, but in particular, during warm to hot weather months. The well-balanced combination of weight, stretch, quick drying properties, and durability makes the TRS cloth almost a winner in the field. It was a forgone conclusion that our best-selling Raider Short was next in line to use our TRS material. A bomber, purpose driven style, rugged build, and made to last season after season. Unlike much of the garment industry, we make our goods to last and perform longer. On average most of our customers will wear and use our apparel styles for 5 years or more before wearing them out. Trends come and go, but expertly made, functional designs have staying power and stamina. Our Raider Field Short TRS is as versatile as the adventurer who wears them. From packrafting, overlanding, backpacking, jungle trekking to trying out a new rum at your favorite tiki bar, these shorts have you covered.”

The Raider Field Short TRS is available for $123.00 via their website, prometheusdesignwerx.com.

Waterproof Pro is a Swedish dive suit manufacturer offering Dry, Semi-Dry and Wet suits.

This lightweight assaulter suit is Al called the Tactical Breathable Drysuit is made of waterproof breathable laminate and combines a form fitting design with mobility. Customers get to customize a basic silhouette to suit their mission.

Waterproof Pro products can be procured by agencies, departments, and units in Canada from Rampart International.

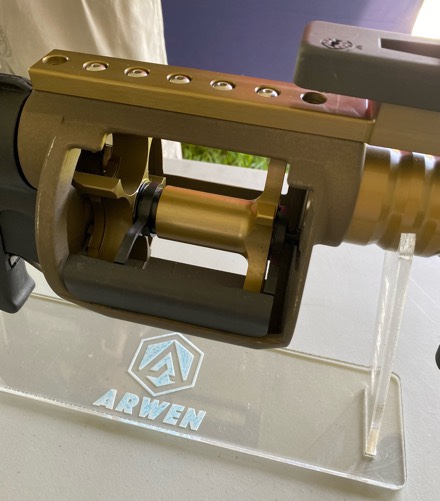

When I saw the sign for ARWEN I was taken aback. I hadn’t seen that company in a long time. If you’re around my age, you may remember ARWEN from its Enfield days, as the 37mm Anti Riot Weapon ENfield gas and nonlethal baton launcher used by British forces during “The Troubles” in Northern Ireland.

Currently offered in two variants, both the single and multi-shot (5 rounds) versions offer a roomy breach which makes it easy to get rounds in.

The ARWEN is currently in use with Canadian LE. Apparently, in 2001, Canadian Police Ordnance Company Inc., acquired rights to the anti-riot device and began production of the third generation gun. This includes foregrip and Picatinny rails. Last Fall, Kwesst bought CPOC and are in the process of updating it further.

Kwesst products can be procured by agencies, departments, and units in Canada from Rampart International.