ARLINGTON, Va. (AFNS) —

The Department of the Air Force identified six locations May 15, to host experimental Air Task Forces that will test new methods to generate more efficient, integrated deployable Units of Action.

As part of a pilot program, the following installations are expected to receive an ATF command echelon this summer, pending the successful completion of the National Environmental Policy Act process. This is a step toward forming the new Air Force combat wings as Units of Action.

• Davis-Monthan Air Force Base, Arizona

• Scott AFB, Illinois

• Joint Base San Antonio, Texas

• Dyess AFB, Texas

• Fairchild AFB, Washington

• Seymour Johnson AFB, North Carolina

“These pathfinding ATFs will work and train together throughout their AFFORGEN cycle to ensure they are at peak effectiveness on Day-1 of any deployment,” said Air Force Chief of Staff Gen. David Allvin. “That’s a significant change from how we deployed over the last 20 years, but the threat has evolved and so must we. The first ATFs will also be learning organizations and shape our forthcoming Combat Wing design.”

Airmen assigned to the ATF will work and train together throughout the AFFORGEN cycle to deploy as Units of Action in fiscal year 2026.

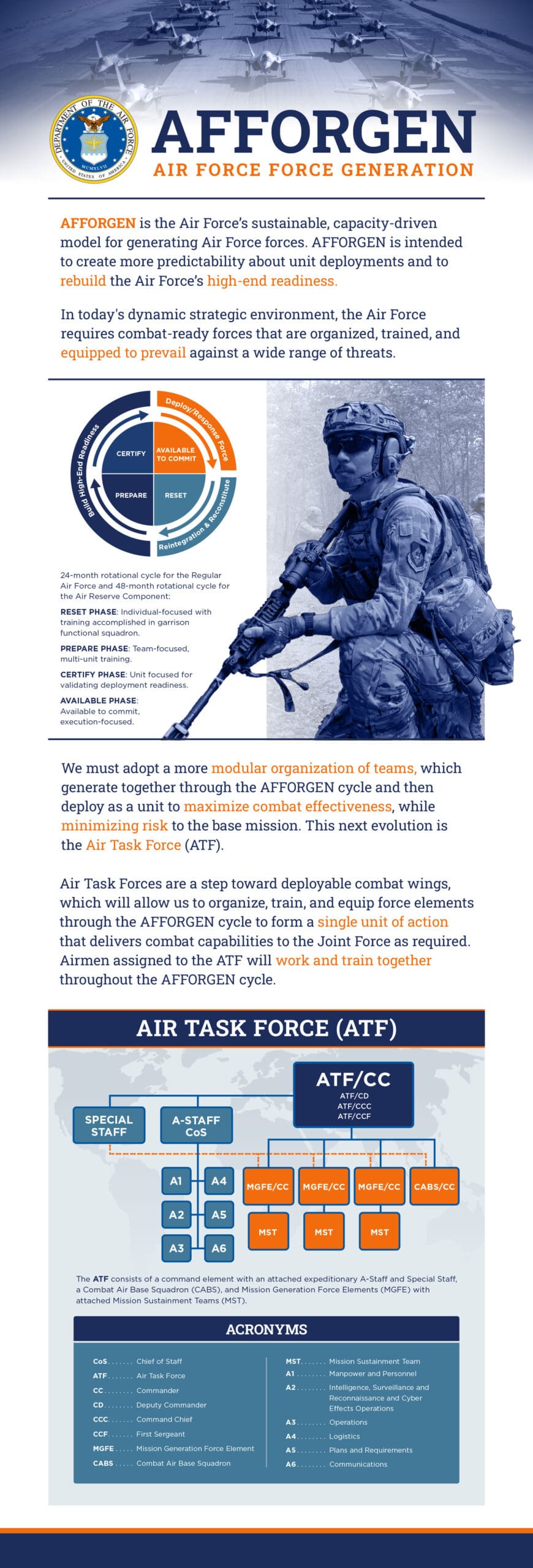

During his Air and Space Forces Association conference keynote in September 2023, Secretary of the Air Force Frank Kendall emphasized the urgency for the Air Force to adapt and innovate in response to growing global challenges with the announcement of ATFs. Clearly defining the force presentation model and rotational demands through the AFFORGEN cycle ensures the joint force receives Airmen prepared for high-end conflict.

Lt. Gen. Adrian Spain, the Air Force’s deputy chief of staff for operations, further elaborated during a panel on Air Task Forces and the Future of Force Presentation at the Air and Space Force Association’s 2024 Warfare Symposium Feb. 14.

“In all the ways that matter, this makes us better prepared,” Spain said. “During the Prepare and Certify phases of the AFFORGEN cycle, Airmen will develop into cohesive units, attuned to each other’s strengths and weaknesses. This preparation is key to ensuring that, when deployed, these teams can operate effectively under pressure and achieve their objectives with precision.”

The Expeditionary Air Base model which first deployed in October 2023, served as a critical first step in the transition. The next step is to adopt a more modular organization of teams which generate together through the AFFORGEN cycle and deploy as a unit to maximize combat effectiveness, while minimizing risk to the base mission.

The AFFORGEN cycle is built to enable Airmen to train and exercise together before being operationally employed together as part of a team. While its implementation differs depending on the mission of each major command, the goal is to achieve a common lexicon, more individual predictability, and greater alignment of readiness generating activities such as large-scale exercises across the Air Force.

The introduction of ATFs marks a significant milestone in the journey toward modernization and readiness, laying the groundwork to ensure the Air Force maintains a competitive advantage over the pacing challenge.

“This force generation and force presentation model best articulates our capabilities and capacity to the Joint Force and in turn, improves the readiness of our Airmen,” Spain said.

What Airmen need to know about the Air Task Force

• ATFs will enter the AFFORGEN cycle during the reset phase in summer 2024 and will be prepared to deploy beginning fiscal year 2026

• ATFs will team, train, and deploy together throughout the AFFORGEN cycle

• Over time, the elements of the ATF will be incorporated into operational wings

Elements of an ATF

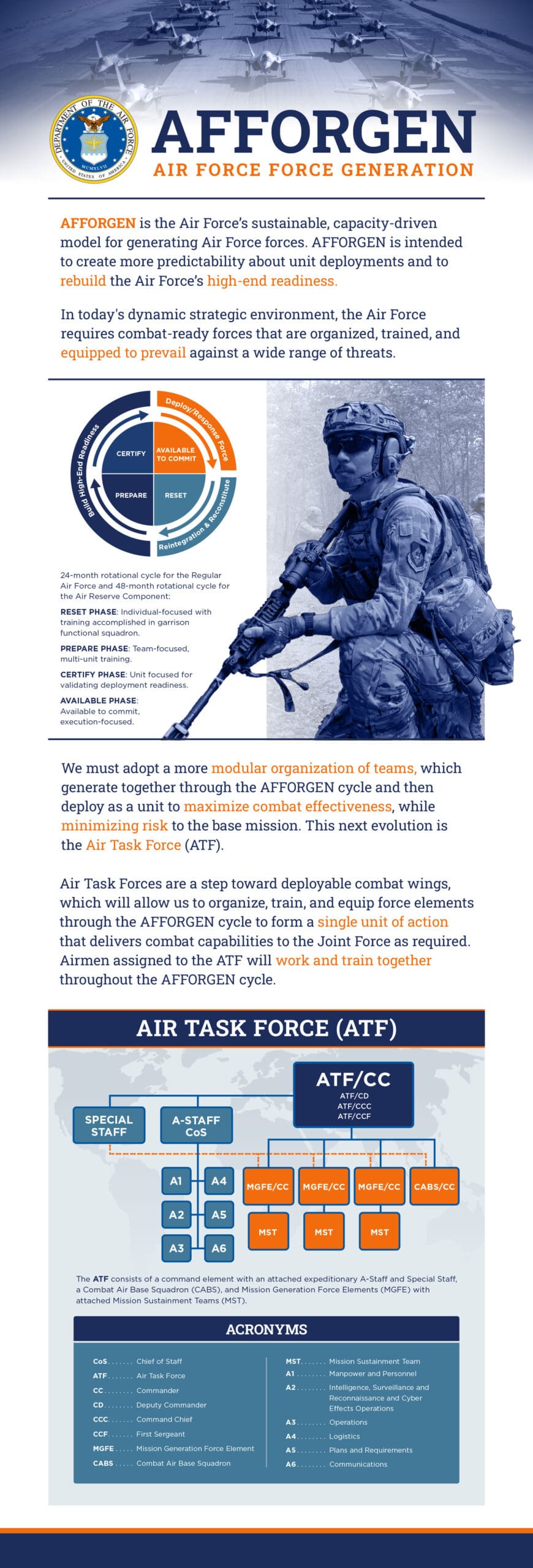

The ATF consists of a command element with an attached expeditionary A-Staff and Special Staff, Combat Air Base Squadron, and Mission Generation Force Elements with attached Mission Sustainment Teams.

The ATF’s A-staff includes a chief of staff who, along with the A-staff, assists with the commander’s interaction with higher headquarters and fulfills the commander’s responsibility to provide resourcing, policy, oversight, and guidance to the various forces under his or her command. The A-Staff is a standardized organizational structure, representing the following Air Force functions: A1 Manpower, Personnel, and Services; A2, Intelligence; A3, Operations; A4, Logistics and Engineering; A5, Plans and Integration; and A6, Communications. The ATF also has a Special Staff to provide staff assistance for the commander.

The Combat Air Base Squadron is the ATF’s primary base operation support element and provides sustainment, protection, and/or airfield management. The ATF commander determines support requirements based upon deployment location and mission. A standard CABS consists of one Combat Service Support Team – Lead and one to two Combat Service Support Teams capable of supporting from several hundred to several thousand service members, depending on size. CSSTs consists of cross-functional teams each sourced from a singular installation.

The Mission Generation Force Element provides the combat capability of the ATF, for example, an expeditionary fighter squadron or an expeditionary special warfare squadron. The MGFEs train throughout the AFFORGEN cycle at home station as they do today and join their assigned ATF for specific training and certification events throughout the AFFORGEN cycle before fully attaching with the ATF for the available phase.

Mission Sustainment Teams pair with an MGFE to provide mission specific combat support functions to enable agile combat employment and other operations at a Forward Operating Site or more austere Contingency Location. MSTs provide sustainment and protection for the portions of a MGFE moving forward to one or more locations. The MSTs may be able to augment the CABS when at a Main Operating Base.

Where Combat Wings Come In

At the Feb. 12 Air and Space Force Association’s 2024 Warfare Symposium in Colorado, Kendall highlighted the need to evolve the Air Force’s approach to organizing, training, and equipping to maintain a competitive advantage in preparation for great power competition.

“We need these changes now; we are out of time to reoptimize our forces to meet the strategic challenges in a time of Great Power Competition,” Kendall said.

Air Force combat wings will be structured as mission ready Units of Action with the same basic framework as the ATFs. However, as opposed to only coming together during events in the AFFORGEN prepare/certify phase, these operational wings will have all the necessary elements stationed together at the same installation where they can train together on a day-to-day basis. Over time, the lessons learned from the ATFs will be incorporated into our combat wings, with the goal to move toward combat wings as the singular force presentation model for the Air Force.

Combat wings will evolve to deploy as fully trained teams leaving behind functional base commands prepared to continue operating the base in competition, crisis and conflict.

Secretary of the Air Force Public Affairs