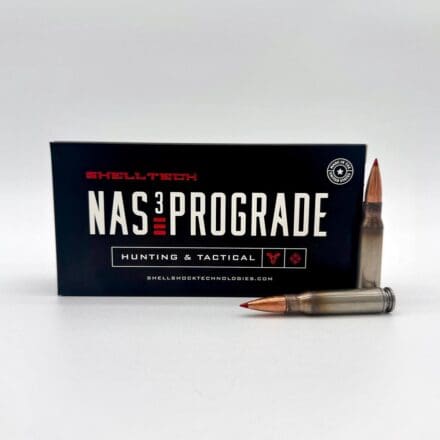

Eubank, KY (September 2025) – Shell Shock Technologies, LLC. (SST), a leading innovator in the ammunition industry, is proud to announce the release of its newest premium ammunition: Shell Tech™ 308 NAS3™ PROGRADE Ballistic Tip Ammo. Engineered to deliver the performance hunters demand in the field: superior accuracy, flat-shooting velocity, and devastating stopping power. Built with the trusted Nosler® Ballistic Tip® projectile and SST’s advanced NAS3 casing technology, the 308 NAS3 PROGRADE provides the consistency and precision that gives hunters confidence with every shot.

At the heart of the cartridge is the 150GR Nosler Ballistic Tip, designed for controlled expansion, deep penetration, and reliable weight retention across a wide range of velocities. Its streamlined polymer tip with a full-tapered jacket and a special lead-alloy core delivers controlled expansion, optimal weight retention, and superior accuracy at long range. The heavy jacketed base prevents bullet deformation during firing, providing a stable platform for the large-diameter mushroom effect upon impact, ensuring deep penetration and decisive stopping power. Additionally, the Ballistically Engineered Solid Base® with its boat tail configuration works seamlessly with the streamlined polymer tip, improving long-range performance and simplifying the loading process. The result is consistent terminal performance, deep penetration, and decisive stopping power in hunting scenarios.

Supporting this proven projectile is Shell Shock Technologies’ NAS³ casing, which ensures ultra-consistent geometry, optimal chamber alignment, and uniform wall thickness. These attributes minimize recoil, reduce inconsistencies, and tighten groupings, giving hunters the reliable accuracy they depend on. Built from a nickel alloy body and stainless-steel head, NAS³ casings are stronger than brass, resistant to corrosion, and designed to withstand the rigors of extreme hunting environments. They are also up to 30 percent lighter than traditional brass cases, reducing fatigue in the field and allowing hunters to carry more ammunition with less weight.

The visible discoloration on each NAS³ case neck is the result of heat annealing, a process that improves bullet grip, enhances neck tension, and increases consistency shot after shot. Combined with SST’s eco-friendly, lead-free design, hunters can count on cleaner barrels, reduced fouling, and environmentally responsible performance without sacrificing results.

“The introduction of our 308 NAS3 PROGRADE Ballistic Tip Ammo represents a major step forward in our commitment to innovation, performance, and reliability,” said Peter Foss, Managing Partner and CEO of Shell Shock Technologies. “By combining our advanced NAS3 casing with Nosler’s proven Ballistic Tip technology, we’ve created a cartridge that gives hunters the confidence they need in the field: accuracy at extended ranges, flat velocity, and the stopping power to make every shot count.”

Delivering a muzzle velocity of 3,050 feet per second, superior accuracy, reduced recoil, and flawless cycling, the 308 NAS³ PROGRADE gives hunters the flat trajectories and stopping power needed for elk, deer, and other challenging pursuits. Hunters will find it to be the ultimate ally in achieving consistent results.

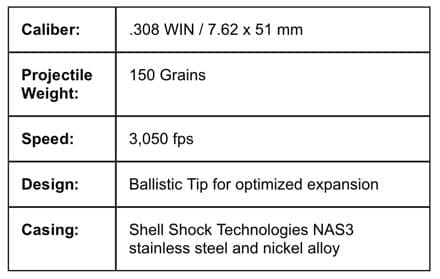

Shell Tech 308 NAS3 PROGRADE Ballistic Tip Ammunition Specifications:

The Shell Tech 308 NAS³ PROGRADE Ballistic Tip Ammo is available now in 20-round boxes for $54.95, with a subscription option offering 15 percent savings.

?Keep up with Shell Tech’s advanced ammunition on the website and social media platforms: Facebook, Instagram, and YouTube.