The Dragontail Limited combines a suede upper with lacing down to the toe and an anatomical tongue.

Below is Garmont’s GTF Diamente outsole.

Now get this, US sizes 4-14. That’s the big story here.

The Dragontail Limited combines a suede upper with lacing down to the toe and an anatomical tongue.

Below is Garmont’s GTF Diamente outsole.

Now get this, US sizes 4-14. That’s the big story here.

Casualty movement can be a complex task which METT-TC (Mission, Enemy, Terrain and Weather, Troops and Support Available, Time Available, and Civil Considerations) will play a critical role in selecting the most appropriate assets to be employed to physically move casualties in the battlespace or area of operations. With every phase of casualty movement, new challenges are faced and leveraging the best material solutions for the end user can be a decision that is complicated based on the mission’s limitations for weight, cube, and level of training of the end user.

A factor that remains true with regards to casualty movement, as with most tactical equipment, is an increase in capability almost always comes with an increase in cube, weight, and total cost. The end goal of all casualty movement is to provide the casualty a movement platform that is rigid, supports the entire body, and transported with minimal effort while maintaining the ability to monitor and treat the casualty. Let’s take a look at the different options in the context of the Phases of Care for Tactical Combat Casualty Care.

Care Under Fire

In the care under fire (CUF) phase, the quickest and easiest way to move a casualty is by a simple drag or carry. While quick and effective, they each have their limitations. Drags and carries are often best suited for short distance movement to the first available cover as they require a lot of physical effort and will temporarily reduce effective fighting strength while attempting to gain fire superiority. While manual carries can be utilized for longer movements, variations of dragging a casualty without some form of material solution can only be executed for short distances. Casualty drags are often practiced in areas that are smooth and conducive to the task, but in reality, this is rarely the case. Patients can actually be injured further from being dragged long distances, primarily by friction which can quickly abrade through uniforms and equipment. If manual carries are the method of choice for moving in this phase, they must be practiced by all team members on a regular basis for smooth execution.

Occasionally in the care under fire phase, simple poleless litters are employed. Poleless litters come in various shapes, sizes, and materials. Two options for poleless litters are the Ultralight Poleless Litter and the Phantom® Litter. While a poleless litter can fold smaller and is lighter than a traditional rigid litter, they also have limitations. They can be dragged for short periods of time but will eventually wear through the material from friction. Additionally, they require people to carry them in order to transport the patient in a proper position (more people = better position). Most commonly, observed is the patient will be bent at the waist unless six or more people are assigned to carry the patient.

Tactical Field Care

Once the situation is more permissive, better options become available due to time constraints, reduction of threat, and better availability of equipment. This phase includes the transition from where the casualty was injured with movement to either a Casualty Collection Point for further treatment or preparation for loading into an evacuation platform. This is the phase of care where the movement platform is considered relative to both injuries and treatments as well as the platform they will be moved to for evacuation.

Occasionally during this phase semi rigid litters will be employed like the Foxtrot® Litter or Foxtrot® DA Litter. Semi-rigid litters are often smaller than lighter than traditional rigid litters, but with reduction in weight and cube comes correlating reduction in capability. Most products in this category act similar to poleless litters with the added benefit of reduced friction, making them more suitable for dragging longer distances or across varying surfaces. While they are semi-rigid, most will lose their rigidity if carried by only 2 people.

More robust versions of a semi-rigid, litter like the Med Sled VLR, increase in cube and weight but have the added benefit of being vertically or horizontally hoisted in a variety of tactical situations. Most of these more robust products will still leave the patient in contact with the ground so insulation and active heating from a hypothermia solution, such as the HELIOS® System, is important. In hoisting operations, most often the evacuation platforms crew will dictate or provide the device. While semirigid litters are common, a Stokes basket style device is considered the gold standard. Unfortunately, they are not easily carried and require training not commonly found by ground personnel.

During this phase, rigid litters may become available as well. While considered the gold standard of movement for all casualties they are primarily limited in the earlier phases of care due to weight and cube considerations. However, rigid litters offer the benefit of being carried by 2 or 4 team members, optimal patient positioning, and better hypothermia management by reducing contact with the ground. Most dedicated evacuation platforms are also configured to receive and secure most of the commercially available rigid litters due to NATO standardized footprints after years of combined, joint combat operations.

To learn more about casualty evacuation and movement, check out: tacmedsolutions.com/collections/medical-supplies/immobilization-&-evac

The Boxer success story continues. The British government, represented by the European procurement organization OCCAR, and ARTEC, a consortium of Rheinmetall and Krauss-Maffei Wegmann (KMW), have signed a contract extension to supply the British Army with an additional 100 Boxer wheeled armoured vehicles. The contract encompasses three previously ordered variants of the Boxer: the infantry carrier, the command vehicle and the field ambulance.

In issuing the order, the United Kingdom is exercising an option contained in the contract signed in 2019 for the Mechanised Infantry Vehicle (MIV) procurement project, which includes 523 Boxer wheeled armoured vehicles in several variants.

ARTEC will be supplying the vehicles to the UK via OCCAR, the intergovernmental Organisation for Joint Armament Cooperation. The bulk of Boxer production will take place in Britain. Series production is currently getting underway in Germany, after which most of the Boxer vehicles already ordered will be produced in British factories of Rheinmetall BAE Systems Land and KMW subsidiary WFEL.

The additional vehicles just ordered will also be produced in both the UK and Germany. Here, the partners will be drawing on the knowledge and components of the established and expanding British supply chain, which already forms the basis of the first lot of 523 vehicles.

A modular vehicle – versatile and battle-tested

The Boxer is a highly protected 8×8 wheeled armoured vehicle. Its modular architecture enables a greater number of variants than any other vehicle system.

To date, some 1,500 vehicles in twenty different versions have been ordered by Australia and four NATO countries: Germany, the Netherlands, Lithuania and the United Kingdom. Australia, a close partner of NATO, has already taken delivery of a first shipment of 25 Boxer vehicles.

Founded in 1999, ARTEC GmbH is a joint venture of Krauss-Maffei Wegmann GmbH & Co. KG, Rheinmetall Landsysteme GmbH and Rheinmetall Defence Nederland B.V. The company coordinates series production and serves as the point of contact for export enquiries for the Boxer.

April 10th, 2022 – Maxton, NC

The first annual CHRISTENSEN ARMS “BATTLE FOR THE SOUTH” 3-Gun Championship took place at Gryphon Group Security Solutions in Maxton, NC on April 9-10, 2022. Thanks to a collaboration from Vortex Optics and Zoo City Armory, this event was revived to bring a fun yet challenging major 3-Gun match to the south. Team Grey Ghost Precision is no stranger to the range at the Gryphon Group Training facility, and each shooter did very well and genuinely had a blast competing at this event.

The Gryphon Group Training facility offers a variety of stage building opportunities. There was 8 exciting stages for the match including jungle runs, unique bay stages, and natural terrain. There was also several stage with 3-4 MOA targets with 300-400 yard distances and even some 500-600 yard engagements. The round count for the match was 200 pistol, 200 rifle,150 birdshot (shotgun) and 10 slugs.

Team Captain JP Sullivan won Carry Optics Division as well as winning High Military using his GGP320 pistol and GGP MKII Light 556 custom rifle. Shooter Matt Kalisch won the Heavy Division using his GGP MKII Heavy 308 rifle. Bobby Whan also shot very well, competing with his GGP320 pistol and GGP rifle.

While GGP doesn’t make a shotgun yet, each shooter on the 3-Gun team is proficient their custom 12 gauge long guns.

Bobby Whan is a beast with a shotgun. He also competes with a GGP320 built pistol.

Every member of Grey Ghost’s shooting team is active duty military. They each continue to train regularly and compete in several matches around the country each year using Grey Ghost Precision built firearms. We are honored to call them brothers and proud of their accomplishments each year. To learn more about Grey Ghost Precision, visit www.greyghostprecision.com

JP Sullivan’s custom GGP MKII Light Rifle and ‘Battle For The South’ handcrafted trophy by @heathen.bladeworks

Manassas, Virginia – Aimpoint, the leading manufacturer and innovator in red dot sighting technology is pleased to continue the product release of the revolutionary Aimpoint® Duty RDS™ sight – now available to all markets through authorized Aimpoint dealers and at aimpoint.us. Built to meet the demands of today’s law enforcement agencies, this high-grade reflex optic offers Aimpoint premium product quality in a compact package at a budget friendly price point.

With an exclusive law enforcement launch in January of 2022, the optic has quickly set a new standard in its category with proven performance. Packed full of new features, this completely new design from Aimpoint does not compromise on trusted legendary quality while achieving affordability.

The Duty RDS™ offers a bright, crisp 2 MOA dot that’s ideal for short to medium range target engagements and is powered by a single CR2032 battery with ACET technology providing over 3 years of constant-on use at daylight position 7 and even longer on the night vision compatible settings.

For over 45 years, Aimpoint has been the trusted choice of military and law enforcement end users worldwide. We maintain this position by listening to the needs of these end users and creating products that can be trusted to perform under the most demanding conditions imaginable. Aimpoint is proud to stand with the men and women who serve and protect our communities.

For more information on the Duty RDS optic or any other Aimpoint products, visit the company’s webpage and webstore at: www.aimpoint.us

Marine Raiders conduct assaults as a Marine special operations company in Jacksonville, N.C.

SWANSBORO, N.C. – April 11, 2021 – On a daily basis the most important piece of gear an individual would need is an Individual First Aid Kit (IFAK). Hunters and other outdoor enthusiasts, extreme sport athletes, first responders and military personnel can all benefit from life-saving equipment being readily available at a moments notice. IFAK’s can accommodate a multitude of items to save a person’s life. Some of the main essential items that you can carry are:

• Adhesive tape

• Bandage kit

• Nasopharyngeal airway kit

• Trauma shears

• Gloves

• Tourniquet

• Chem lights

• Combat gauze

• Pressure dressing

• Vented chest seal

• Ibuprofen

• Burn dressing

High Speed Gear® offers its ReFlex™ product line that was designed with direct input from active-duty medical personnel and constructed around the medical supplies included in the U.S. Army-issued IFAK. The two-piece system allows you to carry previous medical supplies or other essential items to optimize versatility depending on the field of work that you may be in. The High Abrasion-Resistant Neoprene Kevlar® handles were designed for users to be able to easily find, grab and access the contents of the ReFlex™ IFAK System as quickly as possible.

A U.S. Navy Corpsman assigned to Field Medical Training Battalion-East, deploys a ReFlex™ Med Roll on a simulated casualty during a field training exercise at Marine Corps Base Camp Lejeune, N.C.

“We know and understand the importance of preventive measures that users take by carrying organized medical gear.” said Allison Mitchum, HSGI® Director of Sales & Marketing. “It makes us proud to see all branches of the U.S. Armed Forces utilizing our ReFlex IFAK System in the field.”

Since the release of the ReFlex™, High Speed Gear® has also created alternatives for people to be able to use, such as the ReFlex™ Vehicle Mount and the ReFlex™ Leg Rig for users to be able to carry comfortably, no matter their preference.

For more information about the ReFlex™ IFAK System, visit: What do you carry in your ReFlex IFAK System? – YouTube

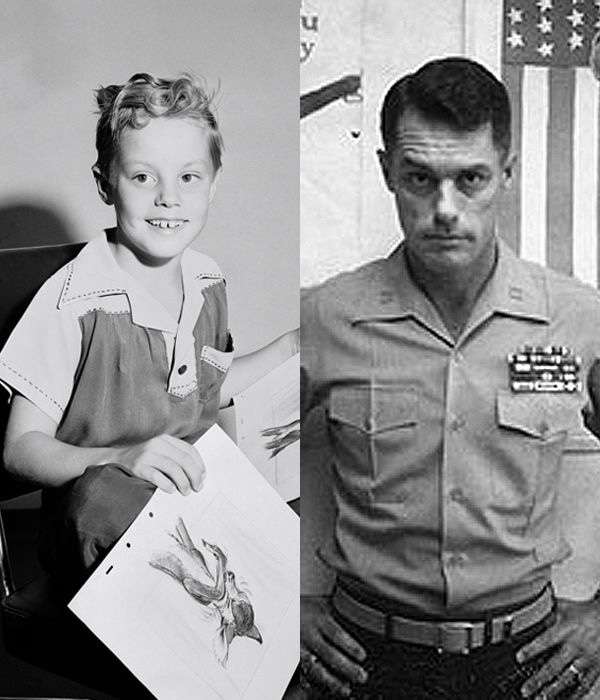

Donnie Dunagan was born in August 1934 and was drafted in 1952 during the Korean War. Instead, he decided to join the Marine Corps where he would spend 21 years in and retire in 1977 at the rank of Major. While growing up in Tennessee, Dunagan’s family struggled to make ends meet. After Dunagan’s family relocated to Hollywood after winning $100 in a talent competition, he rose to the status of a child celebrity. His most recent role was as the voice of Bambi, the beloved baby fawn from the Disney film of the same name.

It was a stark contrast between his Hollywood past and his adolescent years. However, he adapted to the life of a Marine. During his 21-year career, he served three tours in Vietnam, earning a promotion to Major along with a Bronze Star and three Purple Hearts. which was a company record at the time. He was also the youngest drill instructor to don the campaign hat at twenty-seven years. He kept his movie carrier a secret from his fellow Marines throughout this time. He was never ashamed of his past, but like every good military person, you can never give people any ammo to make fun of you. Somethings never change.

He had a brief career as a child actor before being cast as the title character’s voice in Disney’s 1942 animated film Bambi, which has become a classic animated film about a young deer who learns about life in the forest.

Of course, it eventually made its way out. Several decades later, a Marine with whom Dunagan had previously worked on several occasions, including twice in combat, summoned him to his office about a month or so before the two of them were to retire.

Dunagan said, “When I walk into his office, he greets me with, ‘Dunagan! ‘I’d like you to audit the auditors,’ I say. “Dunagan recalls the incident. Being swamped with other work at the time, Dunagan respectfully inquired of him: “General, when do you think I’ll have time to do that?”

And, at long last, the secret he’d been living with for years came to out.

“He looked at me and drew his glasses down as if he were a university professor. There’s a large, red, top-secret folder with my name on it that he managed to get out of some hidden safe somewhere. “You will audit the auditors, Maj. Bambi,” he says as he patted the folder on the table and looked me in the eyes.

Dungan says, “But I enjoy it now when people realize that this old jerk is still alive and that he was Bambi. And I wouldn’t accept anything in exchange for it, not even a darn thing.”

Spring is here and FirstSpear is giving us a look at an extremely popular garment from their all American merino wool apparel line up, the Hooded Field Shirt. This garment is generously cut with an oversized hood with absolutely no hardware making for an incredibly comfortable and highly functional base layer or perfect stand-alone top when temperatures are fluctuating. Perfect for layering under jackets when the temperatures are cool and moisture-wicking properties of wool will help keep you cool in the heat.

• American Merino Wool

• Generously cut for long-term comfort

• Oversized hood

• Low profile cuffs with thumb holes

• Made in the USA

In stock and now shipping in black, commando, sand and heather grey. These are 100% made in the USA with USA materials.

For more information, check out www.first-spear.com/technical-apparel/american-merino-wool/field-hoodie.