Coming Soon

Coming Soon

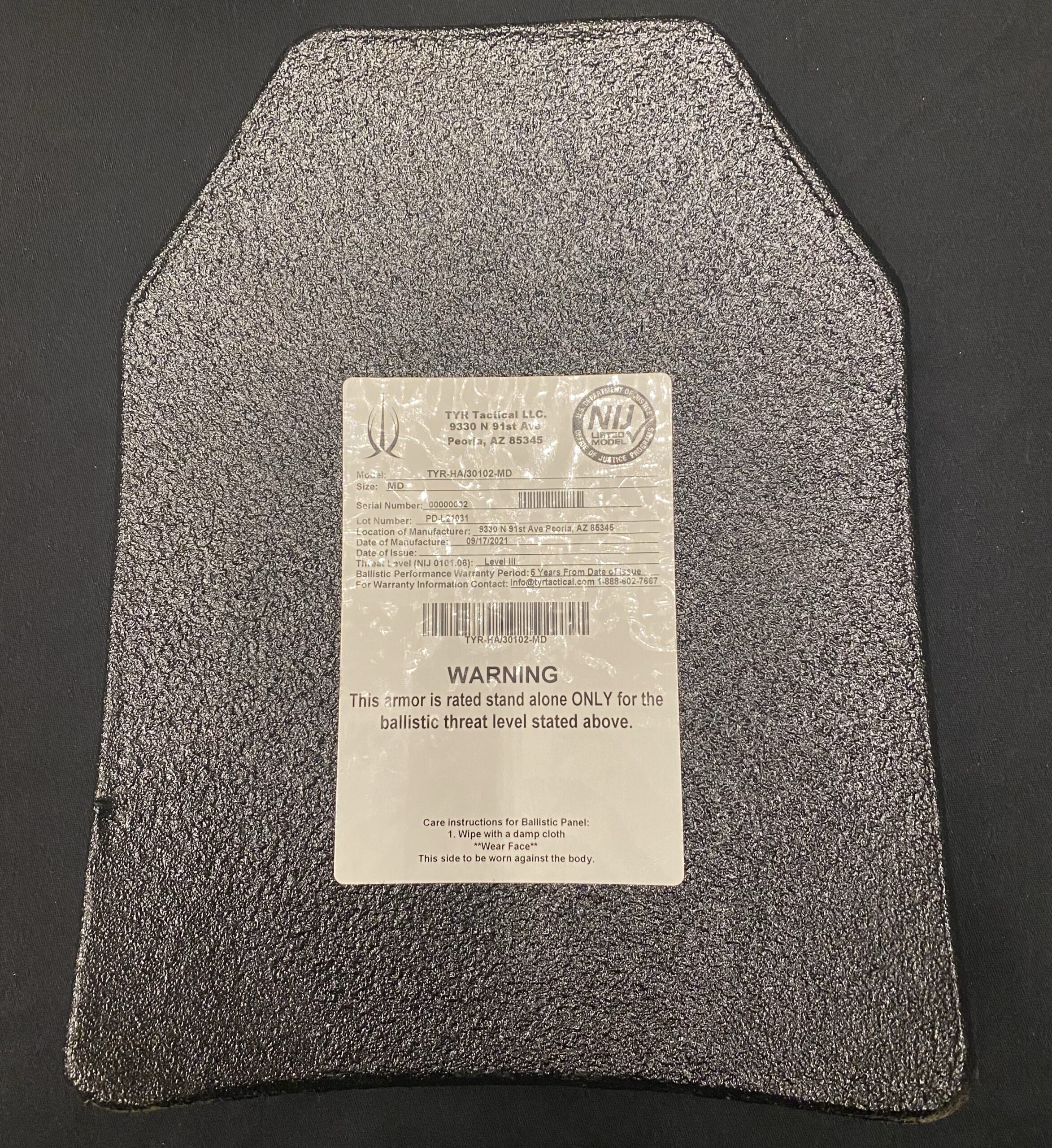

TYR Tactical Canada was the primary driving force behind Operator Expo. They displayed their new Canadian content Level 3 stand alone armor plate, the TYR-HA-30102

This UHMWPE plate weighs 3.31 lbs (medium plate) and is competitively priced.

They also featured two mannequins outfitted with their various kit including shield and uniform.

GASTONIA, N.C. – September 30, 2021– Premier Body Armor, a leader in body armor systems to defend against handgun, shotgun, and high-powered rifle threats, is proud to announce the availability of select Level IIIA Backpack Inserts in Multicam Black™.

“Premier Body Armor’s backpack inserts are custom made for an exacting fit in many backpack designs and offer easy-to-use protection and portable convenience that allows armor to go with you everywhere—no excuses—even onto planes,” said Jason Mammano, Vice President of Marketing and Communications at Premier Body Armor. “The ultimate accessory for your MCB Vertx bag is now available from Premier Body Armor in MCB to match and complete the package.”

These armor inserts are ideal for EDC. The Level IIIA inserts are tested against common handgun rounds such as 9mm, .40, .45, and .44 magnum and Special Threat Tested against 12 Gauge buckshot and slugs, Liberty Civil Defense 9mm, and FN 5.7×28. Inserts are also stab and slash resistant.

Premier Body Armor inserts are specifically designed for functionality and dependability. The .22”, lightweight and soft panel will provide years of service and safety. They are tested to meet the NIJ ballistic standards for Level IIIA and are constructed of USA made Kevlar® and feature a 500 Denier CORDURA® outer shell. Color options for most inserts include Black, FDE, Multicam™, and now Multicam Black.

Learn more about Premier Body Armor and their complete line of armor at premierbodyarmor.com.

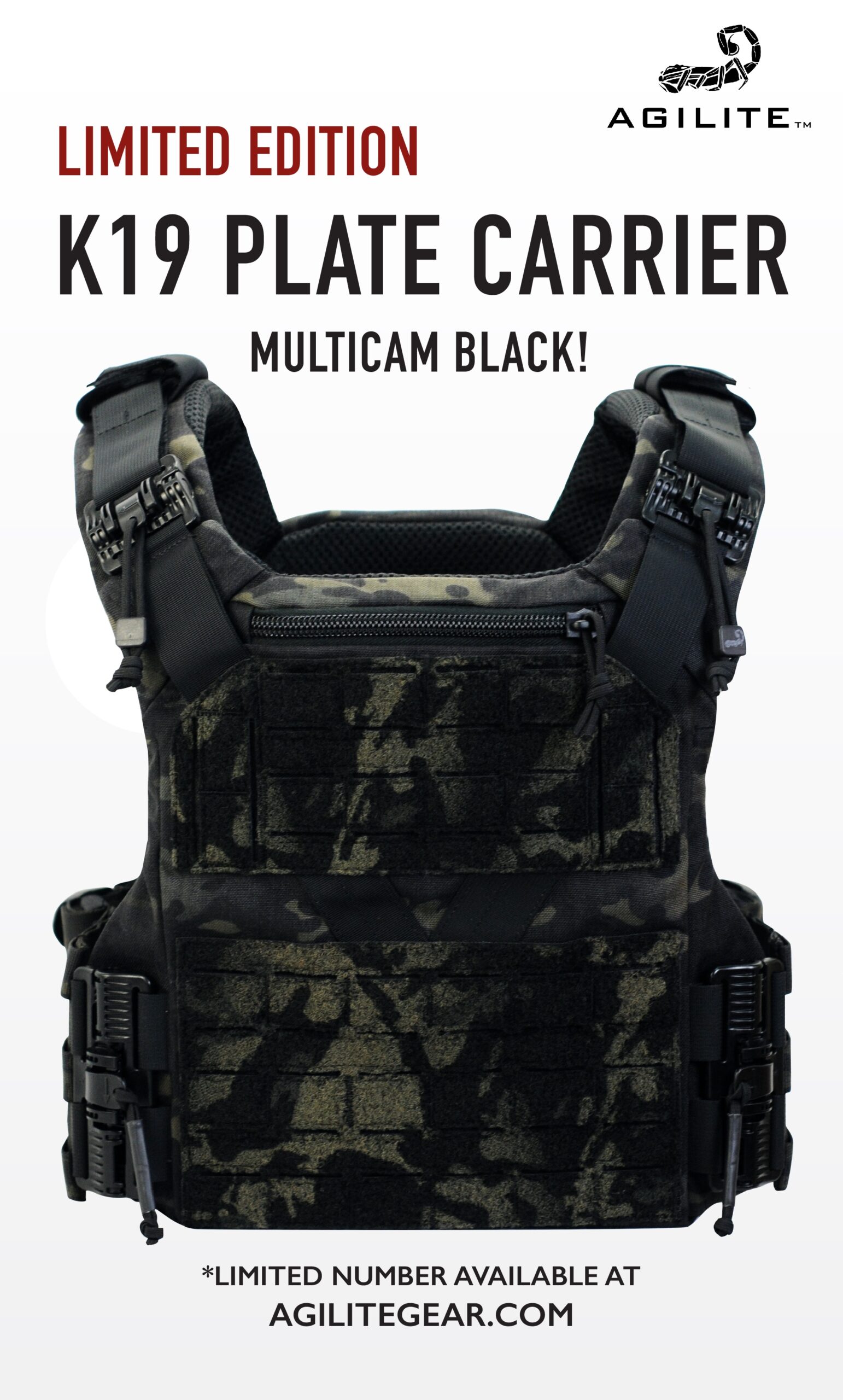

Agilite have made a Special Edition Limited run of the K19 Plate Carrier in Multicam Black which are available at their website now. The Israeli SF carrier is now one of the highest selling plate carriers in the USA and is known for its inordinate comfort. There is currently no plan to re-make this product in Multicam Black so to score one, go to agilitegear.com/collections/combat-gear/products/k19-plate-carrier where it’s available for a short time with free shipping.

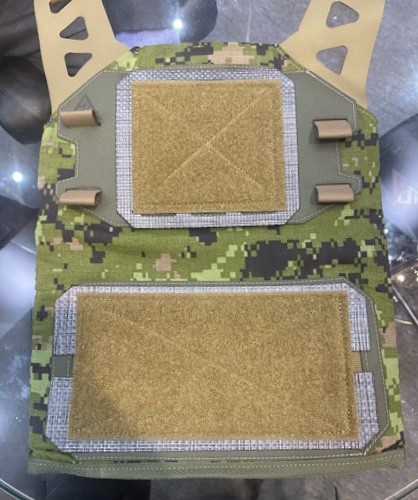

The Chameleon is C2R FAST’s latest creation. It consists of a Base Carrier seen here which accepts skins in different colors and patterns, allowing you to change the camouflage of your vest without buying a new one.

Here’s an example. In less than a minute, this vest was transitioned to MultiCam Alpine.

Here you can see how it works. The skin features two openings which are stretched around Tegris lips to keep the skin aligned and in place.

If you can think of the pattern, they’ve got it, or can do it.

The Chameleon will be available for order as soon as C2R FAST launches their new website in the next few weeks.

Virfex, Inc is pleased to announce its “RAVENTM” Level III Body Armor Torso Plate Insert which offers multi-hit protection against .308 NATO M80, .30-06 M2 Ball, 5.56x45mm M193, 7.62×39 FMJ and 7.62×39 MSC is now fully NIJ0101.06 Level III certified. This is their lightest plate to date. Using DSM Dyneema(R) Ultra High Molecular Weight Polyethylene and Virfex’s proprietary manufacturing technologies, they minimize weight and thickness while maximizing multi-shot protection. The RAVENTM is designed to provide “all-day protection” for police officers,

federal agents, first responders, prison guards, private security, cash-in-transit drivers, and others in need of protection from the vast majority of domestic threats.

Plate Specs

Weight: 2.5 lbs. (10×12 Shooter Cut) Thickness: 1.1″

Curve: Single

Warranty: 10 Years

Plate Applications: External Carriers, Plate Carriers, and Tactical Body Armor

Origin: All Virfex Body Armor Plates and Carriers are designed and manufactured in Massachusetts. All of the RAVENTM’s raw materials are proudly Made in the USA!

Virfex, Inc’s President, Gus Dehni, stated, “We are very pleased to receive full NIJ 0101.06 Level 3 Certification for our first multi shot plate entry into the body armor market. We believe with our technical expertise and raw material partners, Virfex will have Level III+ and Level IV plates NIJ 0101.06 certified within 2022”

About Virfex, Inc: Virfex is a U.S. based body armor manufacturer specializing in lightweight and affordable personal protection products. Virfex also designs armor carrier systems intended for professional duty use amongst Law Enforcement and Military Agencies.

About National Institute of Justice: The NIJ is the research, development and evaluation agency of the U.S. Department of Justice. The NIJ promulgates standards for body armor used by law enforcement agencies in the USA. The NIJ reviews submitted body armor against their standards including the review of the armor’s design, test data from NVLAP accredited labs and on-site inspections of manufacturing facilities. The NIJ Level III standard requires protection against six shots from a reference .308 NATO M80 bullet.

Every minute of every day, military personnel, law enforcement officers and security professionals around the world are putting their lives on the line to protect others. For these brave men and women, it’s just part of the job.

At DuPont, we believe that the brave deserve the best. We’re proud of our long history of helping to protect these everyday heroes and we are committed to providing new, innovative solutions as the threats they face continue to change and evolve.

That’s why we’ve added DuPont™ CoreMatrix™ Technology to our family of protection solutions, which includes innovative products such as DuPont™ Kevlar® for ballistic vests and shields, and DuPont™ Tensylon® for hard armor applications.

DuPont™ CoreMatrix™ Technology enables the lightest, most flexible ballistic solutions that meet National Institute of Justice (NIJ) standards for enhanced durability. This globally patented technology, available exclusively from DuPont, uses needle punching technology to infuse fiber in the Z direction, creating a monolithic structure used in today’s most advanced body armor packages.

DuPont™ CoreMatrix™ Technology disperses the impact energy 360 degrees, significantly enhancing ballistic performance compared to traditional woven structures that are stitched together and primarily disperse energy in the X and Y planes.

“By adding this third dimension of protection, DuPont™ CoreMatrix™ Technology combined with DuPont fiber technologies provides unmatched strike face performance while delivering superior protection against edge shots, multi hits and fragment threats,” said Steven LaGanke, Global Defense Segment Leader, DuPont Water & Protection.

This superior ballistic performance allows for lighter weight solutions, which are more comfortable to wear. Hybrid package solutions made with DuPont™ CoreMatrix™ Technology also offer increased flexibility and a softer feel against the body, further enhancing comfort.

“When it comes to choosing soft armor or bomb suits, the level of protection against ballistic threats always takes priority over the wearer’s comfort. After all, it could be a matter of life or death,” noted LaGanke. “With DuPont™ CoreMatrix™ Technology, there are no tradeoffs required. That’s why we believe it is a paradigm shift in ballistic protection.”

In addition to enabling comfort without compromise for wearers, hybrid package solutions made with DuPont™ CoreMatrix™ Technology mean ease of manufacturing. These hybrid fabric solutions are available in different layer counts and yarn deniers so there are fewer SKUs to keep in inventory and there is no need for layer counting or complex design. Manufacturing time is also significantly reduced because a simple “stack & tack” method is used, and no labor-intensive quilt stitching is required.

DuPont™ CoreMatrix™ Technology combined with DuPont fiber technologies opens a world of possibilities. It gives manufacturers greater design freedom than ever before to deliver the best, most flexible and lightest weight solutions available to protect those who put their lives on the line to protect others.

To learn more about DuPont™ CoreMatrix™ Technology, visit www.dupont.com/brands/core-matrix