TenCate Advanced Armor is pleased to announce the achievement of the designated aerospace AS9100 certification for its manufacturing and program office facilities in Hebron, Ohio. This certification strengthens TenCate Advanced Armor’s competitive position and standardizes quality, reliability and safety processes across its aerospace and defense programs.

With the award of the AS9100 certification, TenCate Advanced Armor has positioned itself as one of the only vertically integrated manufacturers of armor and force protection equipment in the United States operating under this stringent standard. Attaining the AS9100 certification is a major strategic achievement for TenCate Advanced Armor and has entailed increased attention to continuous improvement, operational control, supplier performance as well as quality management, processes, and procedures. The achievement marks another milestone in TenCate Advanced Armor’s enterprise to build a survivability manufacturing center-of-excellence at its facilities in Hebron, Ohio.

“Moving to the AS9100 quality standard made sense based on who TenCate Advanced Armor’s customers are,” said Todd Dunnagan, Vice President – Sales and Business Development at TenCate Advanced Armor. “Many of our customers supply the aviation industry and the DoD. Adopting the same quality management system that our customers use will provide both transparency and confidence that they are receiving the highest quality lifesaving equipment available. AS9100 will provide us the necessary metrics to not only measure our performance as a supplier, but it will also allow a streamlined means of continuous improvement to all of our employees, resulting in the best product for our customer today and in the future.”

The AS9100 certification reflects TenCate Advanced Armor’s commitment to meeting and exceeding the increasingly stringent industry requirements for aerospace related products. The AS9100 certification expands upon TenCate Advanced Armor’s existing ISO 9000:2008 Quality Management System, adding 80 additional requirements and 18 amplifications of existing requirements.

AS9100 was developed in accordance with NASA, the DoD, and the FAA, and is managed by the International Aerospace Quality Group (IAQG). This standard is strongly supported and adhered to by major aerospace OEMs and is being required by vendors within the supply chain on an increasing basis.

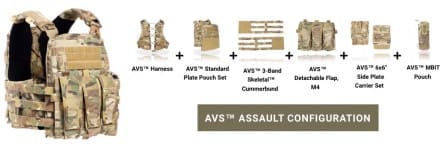

TenCate Advanced Armor USA provides survivability systems to private entities and for large multi-year government programs, uniquely designed for land systems, watercraft, and aerospace platforms. Capabilities also include state-of-the-art protection solutions as a tier one provider of personal protection products (P3) for police departments, federal agencies, and government programs. TenCate Advanced Armor is an OEM-independent entity that can partner with government and industry to analyze, advise, design, integrate, develop, manufacture, and manage survivability programs across life cycles.

www.tencateadvancedarmor.com