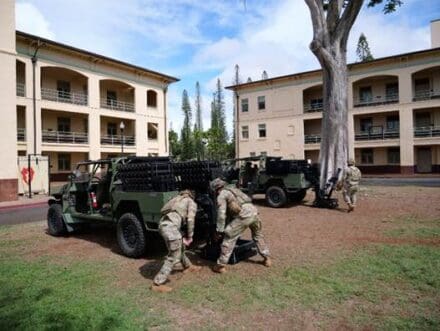

TAMPA, FL – (29 October 2025) – In the Pacific Ocean on the Hawaiian island of Oahu, soldiers from the U.S. Army’s 2nd Battalion, 35th Infantry Regiment trained and conducted tactical scenarios and simulated combat operations using the Scorpion Light 81mm mobile mortar system from Global Military Products. This effort, part of the U.S. Army’s Transformation in Contact (TiC) 2.0, was held at Schofield Barracks to help enhance the mobility, lethality, operator safety and air transportability of these assets.

The TiC 2.0 event, held from Oct. 20-25, provided soldiers with a hands-on opportunity to evaluate next-generation equipment in realistic field scenarios. Without any changes to the formation or concepts of operations, soldiers were able to emplace, fire rounds and displace faster than ever before, with the Infantry Squad Vehicle – Utility (ISV-U) variant able to carry the Scorpion Light 81mm mobile mortar system and 72 mortar rounds.

“Our participation in TiC 2.0 underscored the immense value the Scorpion Light brings to the modern fighting force,” said James Knight, senior manager, Defense Systems and Energetics, Global Military Products. “The soldiers’ feedback was invaluable and further validated the system’s ability to provide rapid, highly mobile, precise and survivable indirect fire. We are proud to be a part of the Army’s mission to field the next generation of combat-effective equipment.”

The tactical scenarios included tactical emplacement and displacement operations, highlighting key features of the Scorpion Light mobile mortar system:

Rapid Deployment and Mobility – The Scorpion Light system, mounted on the ISV-U, demonstrated its ability to emplace, fire and displace in under two minutes. This “shoot and scoot” capability is critical for survivability on a modern battlefield, allowing mortar teams to engage targets and reposition before an adversary can return effective counter-battery fire.

Automated Fire Control System – An advanced digital fire control system enabled rapid, accurate targeting and re-aiming with minimal crew intervention. Soldiers used this capability to engage multiple targets quickly and efficiently during simulated combat operations. The system can also operate with third-party fire control.

Enhanced Capability for Expeditionary Forces – With its ability to be internally transported by a CH-47 Chinook helicopter, the integrated Scorpion Light and ISV-U platform proved its suitability for rapid deployment in remote and austere environments. The event demonstrated how the system can provide critical indirect fire support to light infantry formations.

The two Scorpion Light systems will stay in Hawaii to take part in planned Joint Pacific Multinational Readiness Center (JPMRC) training exercises in early November where the system will be transported via C-17 for air insertion to participate in multiple days of combat scenarios.

The direct feedback gathered from soldiers during TiC 2.0 is another integral part of the Army’s modernization process. This feedback will directly inform future improvements and guide acquisition decisions for mobile mortar systems.

The Scorpion Light’s success in Hawaii follows other recent U.S. evaluations, including a live-fire demonstration with the U.S. Marine Corps at Marine Corps Base Quantico. A version of the same system is also seeing operational success in Ukraine. Scorpion’s modular design and proven capability continue to be recognized across the U.S. and with allied forces seeking mobile, lethal and survivable fire support solutions.