This article was first published in 2014 and I thought it would be a great way to kick off the new year.

I just realized that many of my readers have no idea what Objective Force Warrior or its follow-on, Future Force Warrior are all about and I’m afraid some may think it’s something new. Objective Force Warrior was one of many Soldier Modernization Programs which trace their way back to Soldier Integrated Protective Ensemble in the early 90s to 21st Century Land Warrior to simply Land Warrior and then OFW in the early 00s. You could go on for days talking about what they wanted it to do. If you want to really delve into it, download a vision document below.

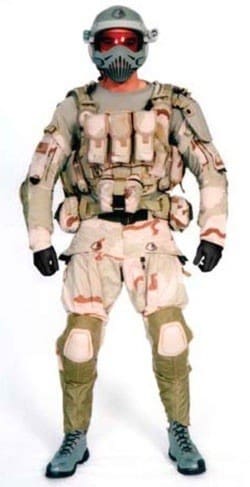

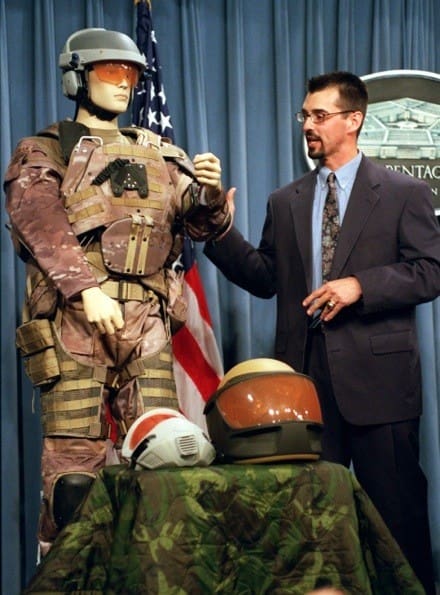

What’s important to you is that it’s where Crye Associates made their bones and many staples of modern Soldier Systems spun out from that program. Working in conjunction with other firms such as Juggernaut Defense and Artisent (which sold off as Ops-Core to Gentex) as well as large contract system integrators, Crye was responsible for the clothing, load bearing and armor components of this Soldier Digitization effort.

What’s important to you is that it’s where Crye Associates made their bones and many staples of modern Soldier Systems spun out from that program. Working in conjunction with other firms such as Juggernaut Defense and Artisent (which sold off as Ops-Core to Gentex) as well as large contract system integrators, Crye was responsible for the clothing, load bearing and armor components of this Soldier Digitization effort.

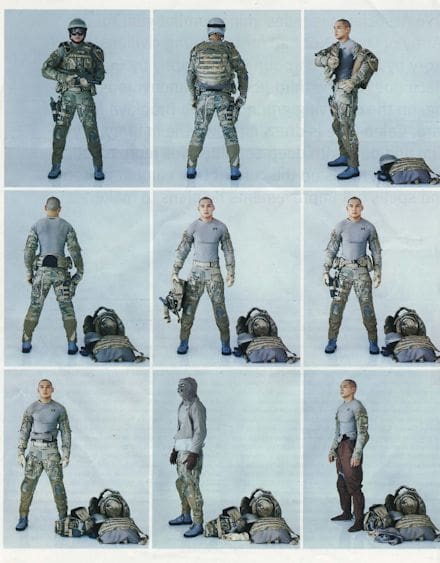

As with most of these programs, lots of money is poured into the software and comms portion and relatively little effort and funding is put toward the clothing and individual equipment components. With many of these programs actual development of the system’s digital operating environment becomes virtual and during program reviews and Congressional dog and pony shows, Crye’s efforts became the face of the program. They produced prototypes that a Soldier could wear and that looked unlike anything else out there. I’d say that they kept that program moving for as long as it did. The clothing and armor developed by Crye was something you could actually see and lay your hands on. Eventually, after a name change to Future Force Warrior and facing actual combat in multiple theaters, the Army let the project drift away with the C4I component transitioning over time to Nett Warrior.

Industrial Design house Crye Associates founded Crye Precision based on the success of their work on FFW and after commercialization, caught the eye of the Special Operations community. The rest you should know.

Ultimately, four critical Soldier Systems technologies find their roots in FFW and with Crye:

MultiCam Camouflage Pattern – It began life as Scorpion for use with FFW but Crye Precision refined the pattern for commercial use and later provided modified variants of the pattern for both the UK (Multi Terrain Pattern) and Australia (Australian MultiCam Pattern). In 2009, the US Army selected MultiCam for use in Afghanistan as the Operation Enduring Freedom Camouflage Pattern (OCP). In 2010, Crye Precision developed Woodland and Arid patterns for the US Army’s Camouflage Improvement Effort. They were selected as finalists along with three other companies. In late 2013, Crye Precision introduced four new patterns to complement the decade old Transitional pattern: Alpine, Arid, Black and Tropical.

Combat Uniforms – The concept of producing a shirt that combines a moisture wicking torso with heavy duty sleeves for wear with armor systems was unheard of prior to OFW. The same goes for garments with integrated knee and elbow protection. Now, these concepts are accepted as state of the art.

Crye Armor Chassis – Crye Precision’s armor chassis took an entirely fresh approach to body armor, combining special, ergonomically shaped armor plates in such a way to allow movement. It has been adopted for use by niche forces and has influenced armor design.

Close Fitting Modular Combat Helmets – While the material science wasn’t quite there yet when the OFW/FFW helmet demonstrators were built, several companies produced enhanced combat helmets over the years including Crye Precision’s AirFrame which fits very close to the contour of the head.

ID Magazine did a great article on Crye’s participation in the project which we offer here for historical purposes.