Most of use who grew up at any point between the end of World War II and the first Gulf War have a bit of a romantic notion of the steely eyed killer with a Randall #14 Attack knife strapped to his field gear. If you are like me, you have probably wanted a Randall knife but for whatever reason, you never got around to purchasing one. It might be because they are so expensive, or the long wait time, or that, while classic they are generally shiny knives made from carbon steel that require a lot of maintenance.

But now, all of those excuses have been answered. Vickers Tactical in conjunction with Schoening Tactical is offering three distinct Randall combat models; the #14 Attack, 315 Airman, and #18 Attack-Survival. Called the VST series, they doing an after market mod to the knives to update them a little. Let’s face it, while the Randall designs are iconic, they have remained static for decades.

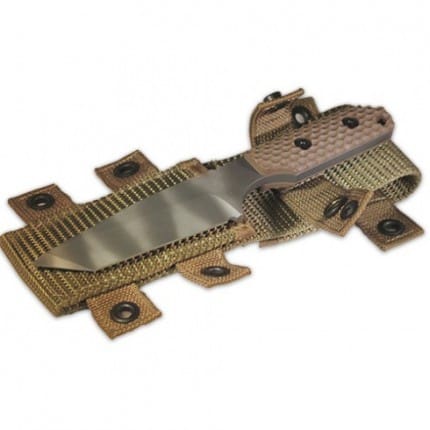

The main thing with the VST series is that they are offering subdued finishes; specifically parkerized carbon steel blades or bead blasted stainless steel blades to both protect the metal and cut down on their high sheen. You CANNOT get a subdued finished knife directly from Randall.

There is another advantage. You will get your knife much sooner than ordering directly from Randall Knives. Randall is running a five year backlog on individual orders since the vast majority of their business is dealer direct. So, if you want to purchase a Randall knife right now you have to go out and search their various dealers and look for the model and options you are seeking. Then, you have to worry about price since these days, Randalls have unfortunately become more collector knives than carry knives for military and LE. I have seen used models going for more than these are being offered for and not the VN-era models either.

It is important to note that only 100 of each model will be available and are priced so that a service member can actually afford one. Remember, Randalls aren’t cheap but these prices are fantastic, especially considering the extras and delivery schedule.

To order visit www.lhgk.us.