Spectra Shield® and Gold Shield® help military achieve goals for reducing soldiers’ body armor weight

MORRIS PLAINS, N.J., Oct. 4, 2016 /PRNewswire/ — Honeywell (NYSE: HON) announced today that KDH Defense Systems will use Spectra Shield® and Gold Shield® ballistic composite materials to create new soft armor vest systems as part of the U.S. Army’s next-generation Soldier Protection System (SPS).

Reducing body armor weight is a key goal for the Army. The SPS is a modular, scalable and tailorable system designed to provide an overall weight reduction of 10 percent. It is comprised of five subsystems, one of which is the Torso and Extremity Protection (TEP) subsystem that aims to achieve a 26 percent weight reduction. KDH Defense Systems will incorporate Spectra Shield and Gold Shield with its own ballistic designs to produce several TEP products.

“The key to reducing body armor weight is combining state-of-the-art ballistic designs like KDH Modular Scalable Vests with next-generation materials like Honeywell Shield,” said Dave Herbener, president and CEO, KDH Defense Systems. “We are committed to leveraging the most innovative technologies to help protect the brave men and women serving in the U.S. military.”

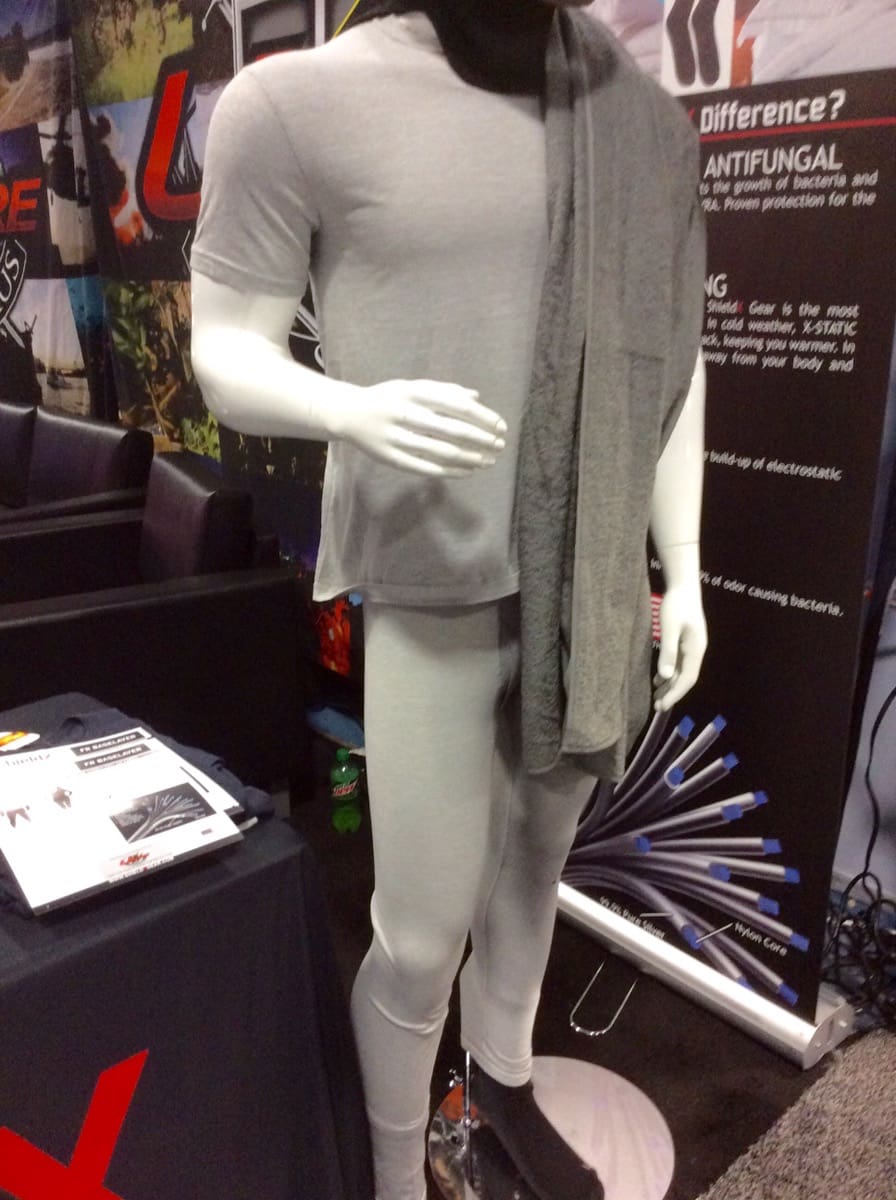

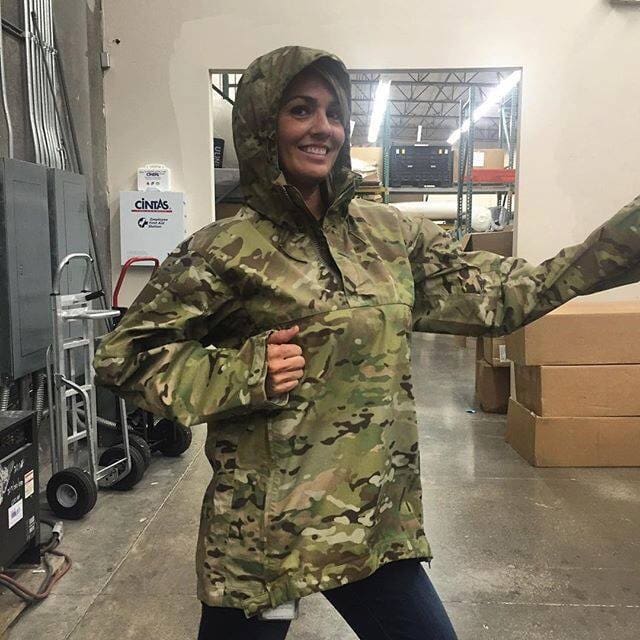

Short Bark Industries is also using Spectra Shield to create Ballistic Combat Shirts (BCS) for the SPS TEP system. The company specializes in soft armor, tactical wear, gear and accessories for the military, governmental agencies and law enforcement.

“Honeywell Spectra Shield is a key material to create armor that meets the military’s rigorous requirements for weight, mobility, flexibility and protection,” said Lisa Held Janke, president and CEO, Short Bark Industries, LLC. “Our team works tirelessly to develop solutions that help protect soldiers from the ballistic threats they face in combat.”

Armor made with Honeywell’s Spectra Shield and Gold Shield products were chosen by soldiers after a U.S. Military Human Factors Evaluation. These armor systems demonstrated improved mobility and flexibility, in addition to reduced weight, compared to systems predominantly made with woven aramid.

“The next generation of soft body armor uses Spectra fiber instead of aramid fiber for optimal performance and protection,” said Lin Murray, armor program manager for military and law enforcement at Honeywell Packaging and Composites. “Our collaboration with innovative companies like KDH Defense Systems and Short Bark Industries ensures that the U.S. military and law enforcement have the most advanced ballistic protection available.”

Spectra Shield technology is a patented Honeywell process designed to optimize the ballistic performance characteristics of Spectra fibers. Spectra Shield and Gold Shield products have been widely adopted and proven for the most advanced armor applications globally, from bullet-resistant vests, breast plates and helmets to combat vehicles and military aircraft—all of which require lightweight solutions and superior performance.

Honeywell maintains an active Spectra fiber and ballistic materials research program focused on continuous improvement and development of high-performance materials. For more information, visit www.honeywell-spectra.com.