JOINT BASE SAN ANTONIO-LACKLAND, Texas (AFNS) —

The Air Force Security Forces Center’s vehicle program delivered the first of new military working dog patrol vehicles to Robins Air Force Base, Georgia, as part of their initiative to modernize Defender equipment across the Air Force.

The improvements from previous patrol vehicles is the result of AFSFC’s vehicle program’s input to the Federal Service Law Enforcement Vehicle Equipment Standardization initiative and is focused on keeping MWD handlers and canines mission-ready.

Security Forces members at Robins learned about the vehicle “hot dog” system, which automatically kicks in when the interior gets too hot for the canines. The full-size sport utility vehicles also have a more spacious interior that gives the dogs a more comfortable ride.

“These new vehicles are definitely an upgrade,” said Staff. Sgt. Matthew Cerulli, MWD handler with the 78th Security Forces Squadron. “I think the best thing is the ‘hot dog’ system, which, in case of an emergency, we have to leave our dog in the vehicle and it gets too hot, an alarm will go off, the windows will roll down and the A/C will crank on to help keep the canines cool.

“However, I think the dogs’ favorite thing is the additional room. We have some large canines and in this new vehicle they can get up and stretch out as needed,” Cerulli added.

“AFSFC’s Vehicle Program seeks efficiencies in vehicle procurement, decreases redundancies and streamlines processes to improve law enforcement readiness,” said Master Sgt. Michael Roth, Security Forces vehicle program manager at AFSFC.

Prior to the FEDSLEVES program, units sourced their own funds to purchase the necessary equipment, which required local vendors to upfit vehicles after they arrived at the installation.

“This program provides security forces units with vehicles that are standardized with pre-installed equipment packages,” Roth said. “We also provide funding for (other) equipment in these vehicles, allowing them to go on patrol immediately. We’re saving the units $17,700 per patrol vehicle and $19,500 per MWD patrol vehicle, so we’re saving the unit both time and money.”

Defenders at Robins AFB and their canines are rolling out in these ready-to-go SUVs.

“These vehicles are a big step forward in keeping our mission ready here at Robins Air Force Base,” said Tech. Sgt. Seth Wilson, 78th SFS kennel master. “Our mission, along with the military working dogs, is to keep everyone on base safe, and these new vehicles allow us to focus more on accomplishing that.”

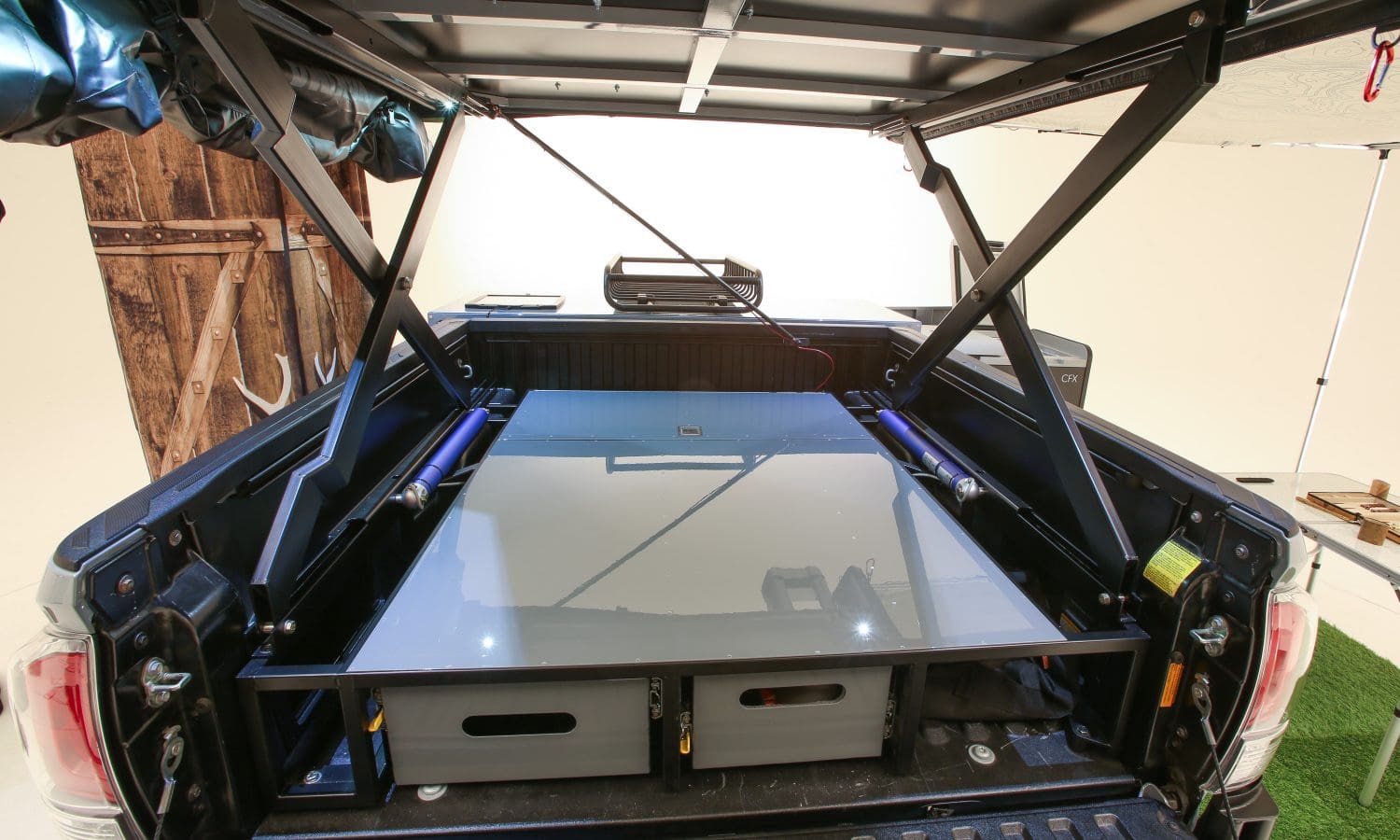

Additional improvements include a radio prep package, which allows operators to plug and play their current radio systems, an upgraded emergency lighting and public address system, and increased weapons storage in the rear cargo area.

“These new MWD vehicles are a product of the hard work of the Air Force Security Forces Center’s Vehicle Program team to modernize the fleet and keep Defenders and their canines mission ready,” Roth said.

Security Forces units can expect to receive the new vehicles as their current ones reach their end-of-life cycle, Roth added.

Story by Malcolm McClendon, Air Force Installation and Mission Support Center Public Affairs

Photos by Joseph Mather