Every trade show I attend I have a favorite product or company and my pick for Warrior West 21 is Soliyarn.

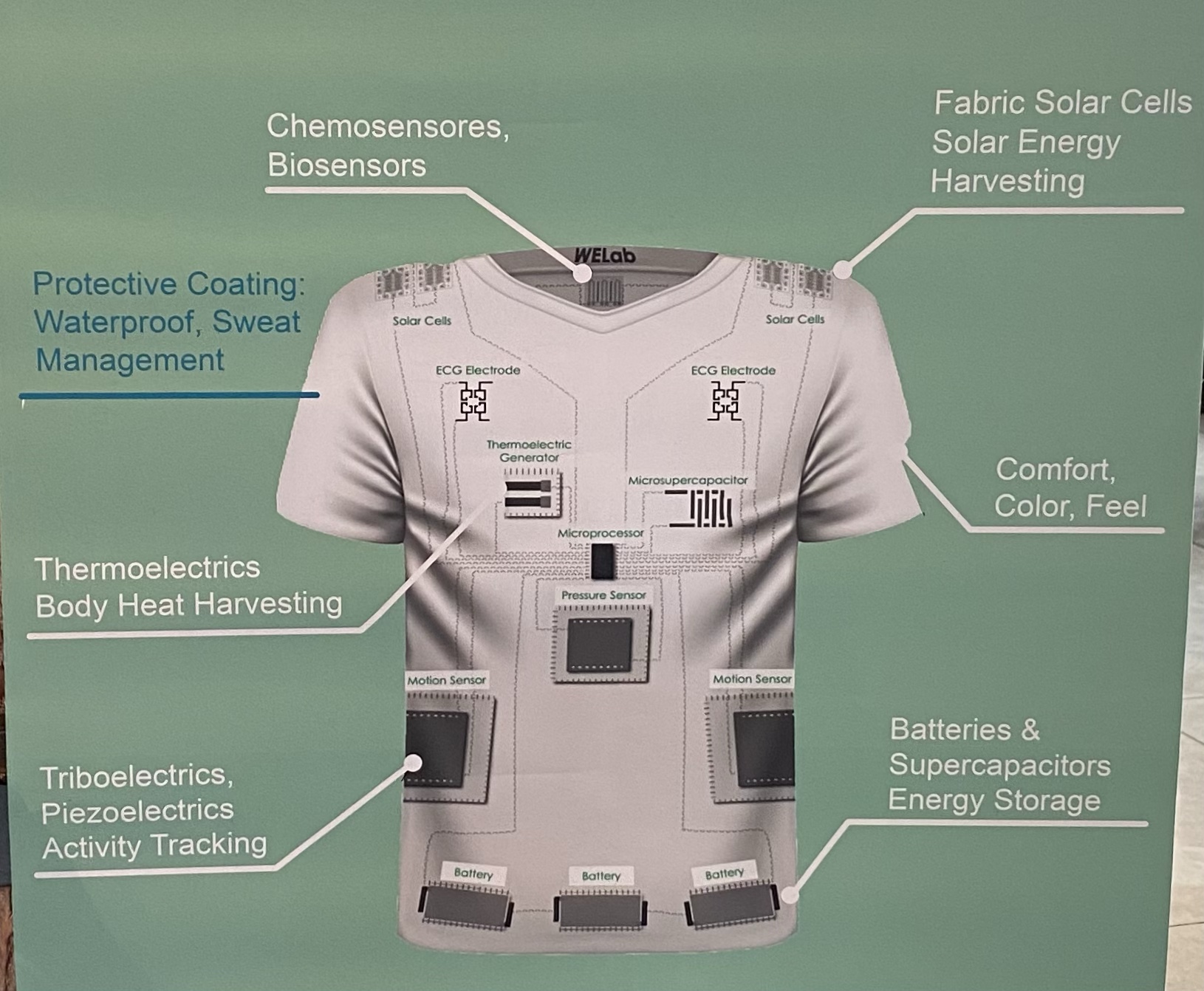

This Massachusetts-based tech company was founded on research conducted at UMass Amherst. In a nutshell, they take raw goods and using a vapor technology seamlessly coat a durable, thin film on to textiles. So far they’ve developed conductive, waterproof and anti-microbial coatings.

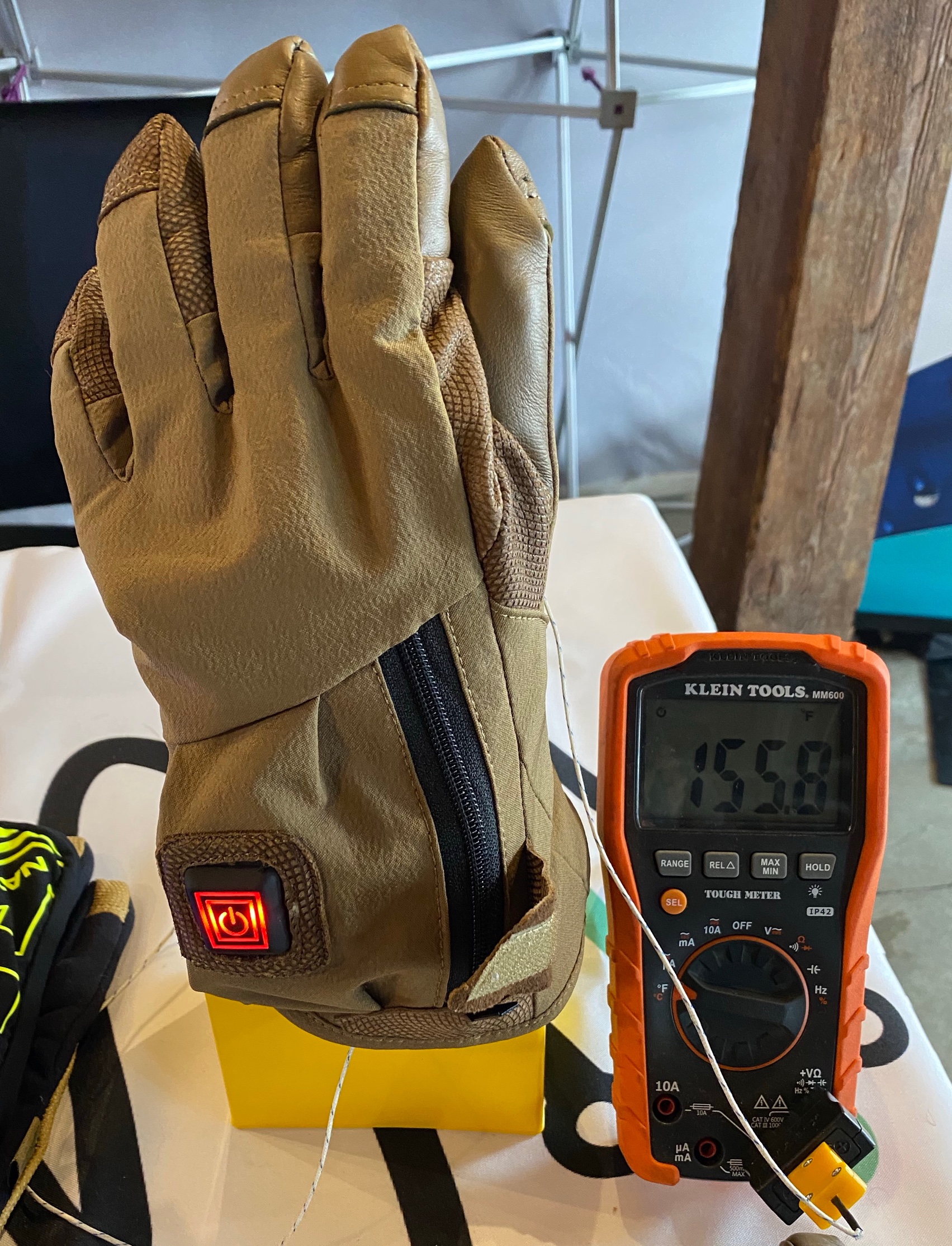

The conductive tech has been used to heat fabric. The technology works. I put a glove on and the back of my hand immediately began to warm up.

Because there are no cables running through the garment, there’s no need to worry about a cable being cut and losing power. Essentially, the fabric serves as a self-healing circuit. As long as there are fibers still connected, there is a degree of power running through the circuit.

They are currently working with Natick on prototypes of a heated HAHO glove. One of the prototypes seen here is from FirstSpear.

They can also treat the material to be water and oil resistant using a PFC free coating. I watched a demonstration of water being poured on this sample of cotton muslin and the water beaded right off. Not only is the fabric going to remain dry, it’s going to retain it’s comfort and air permeability.

I asked a whole lot of questions like whether or not this will also serve as a data bus. Since this technology is so new, they continue to refine what it can and can’t do. This is a story I definitely plan to follow up on.

Soliyarn technologies are available for unit and agency orders from ADS, Inc.

the company’s recent “Where’s the Ammo” video, Remington Ammunition President Jason Vanderbrink is back to give another update on Big Green’s increasing output.

the company’s recent “Where’s the Ammo” video, Remington Ammunition President Jason Vanderbrink is back to give another update on Big Green’s increasing output.