I ran this last year, but I wanted to do it again as I think it is great story.

The Japanese attacked on Pearl Harbor killed 2,403 military and civilians personal. A further 1,178 people were injured in the attack. 19 ships were sunk or damaged, and 188 aircraft destroyed. The efforts of the greatest generation raised all but three (The Arizona, The Utah, and The Oklahoma).

The wreck of the Arizona immediately became a memorial. Passing ships rendered honors to the Arizona and her crew throughout WW2 and still due to this day. Proposals for a permanent memorial started as early as 1943, but not until 1949 did an organized effort began to take shape with the creation of the Pacific War Memorial Commission (PWMC). As the PWMC considered ideas to formally recognize the role of Hawaii during the war, which would include a memorial to the Arizona, Admiral Arthur Radford had a flagstaff placed on the wreck in 1950. He ordered that the colors be raised at the site every day. This modest memorial was later expanded to include a wooden platform and a commemorative plaque.

In 1958, President Dwight Eisenhower signed Public Law 85-344 that allowed the PWMC to raise money on the Navy’s behalf for the construction of a memorial to the Arizona. A fundraising goal of $500,000 was set and the initial response from the public was promising. An episode of the popular T.V. series This is Your Life dedicated to Medal of Honor recipient Rear Admiral Samuel Fuqua. (Then Lieutenant Commander Fuqua serving as the U.S.S. Arizona ship’s Damage Control Officer and first lieutenant, and was on board her during Japan’s December 7, 1941, attack on Pearl Harbor. Though knocked unconscious by a bomb that hit the ship’s stern early in the attack, he subsequently directed firefighting and rescue efforts. After the ship’s forward magazines exploded, he was her senior surviving officer and was responsible for saving her remaining crewmen.)

That initial call for donations raised over $95,000. However, the project quickly stalled as donations dried up. By the start of 1960, only $155,000 had been raised.

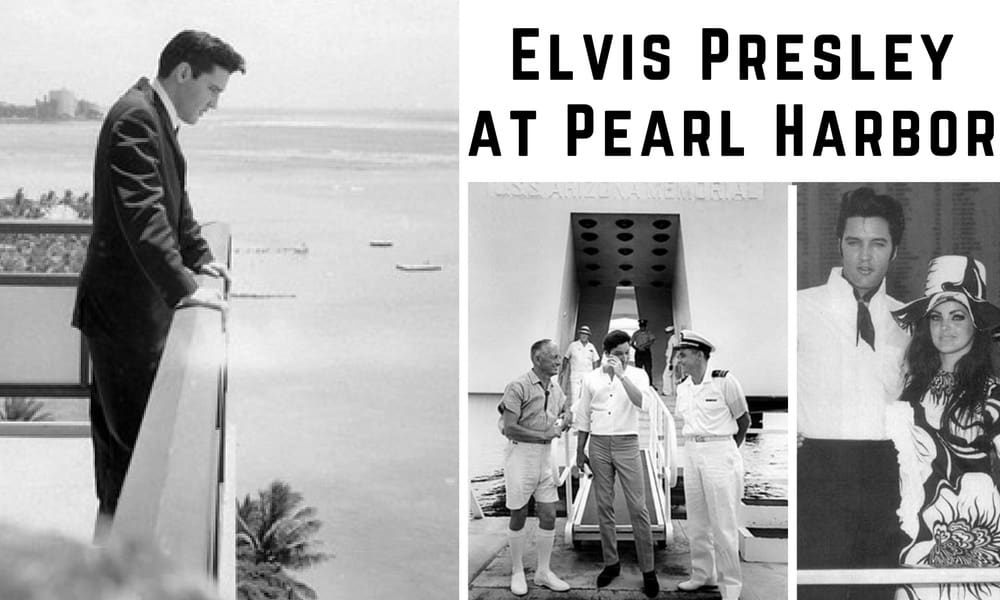

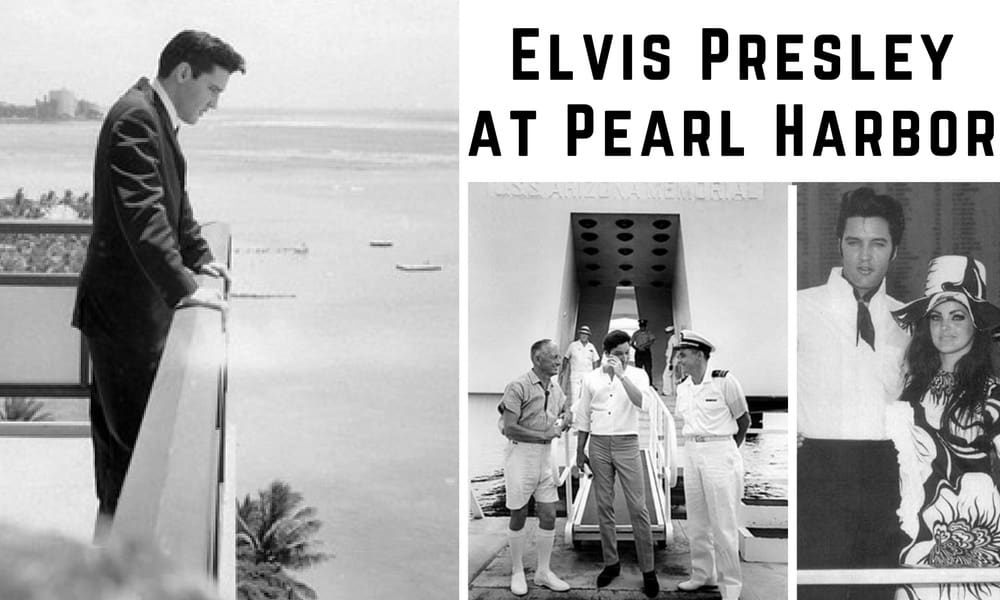

“Colonel” Tom Parker read about the struggling campaign in a newspaper and spotted an opportunity. As Elvis Presley’s manager, he was eager to get a bit of positive publicity for his client who had been out of circulation for a couple of years after being drafted into the U.S. Army. Parker surmised that a benefit concert for the U.S.S. Arizona Memorial would raise much-needed awareness of the fundraising campaign while also demonstrating that Elvis still had drawing power. Elvis was not only pleased to be able to perform for an audience. He was a patriot who genuinely believed in the cause and wanted to help.

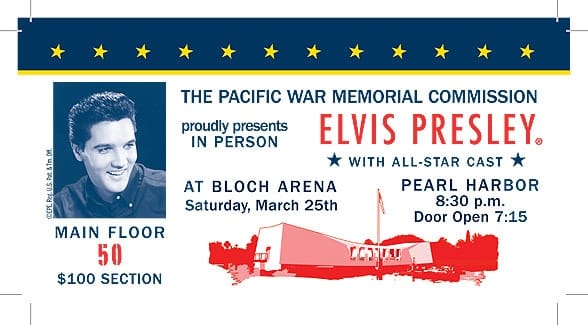

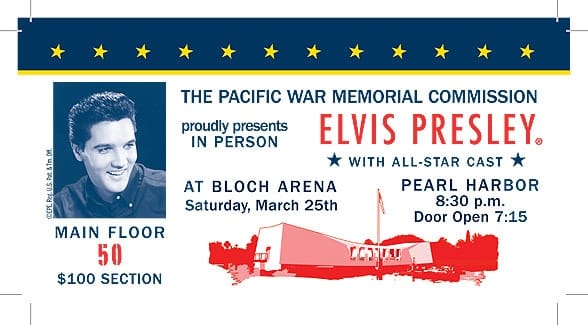

The PWMC accepted Elvis’s generous offer and began making arrangements with the Navy to use the 4,000 seats Bloch Arena at Pearl Harbor as the venue for the concert. It was the same arena that had hosted the “Battle of Music” the evening before the attack in 1941. The “Battle of Music” was a spirited competition to determine the best ship band in the Pacific Fleet. Although they had been eliminated from contention, the band from Arizona was present and played dance music for the attendees. They would never perform again. The entire band was killed in the explosion on the ship the next morning.

With the venue secured and the show scheduled for March 25, 1961, Parker set ticket prices ranging from $3 to $100 and announced that everyone would have to buy a ticket to see the show. Rank usually has its privileges. Still, Parker seemed to take pleasure in rebuffing admirals and generals who approached him about complimentary tickets. When he said he everyone had pay, he meant everyone had to pay — even the performers. Elvis bought a $100 ticket for himself then bought dozens more to give to staff and patients at a military hospital.

After a brief introduction by Rear Admiral Robert Campbell of the 14th Naval District, Elvis took the stage as hundreds of teenagers screeched in excitement. The King looked resplendent in his signature gold lame jacket with silver sequin lapels. He let out a brief yell of his own in response to the ecstatic audience before launching into his hit “Heartbreak Hotel.” All accounts state that Elvis was in peak form, giving an enthusiastic and energetic performance that included favorites “All Shook Up,” “Don’t Be Cruel,” “Are You Lonesome Tonight,” and “It’s Now or Never.” He finished the show with a rollicking version of “Hound Dog,” during which he slid across the stage on his knees. The 15-song set, and 45 minutes of stage time were among the longest of his career. The concert would also be his last for 8 years.

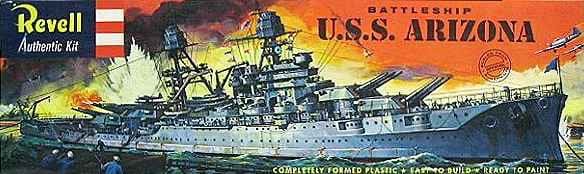

The benefit was a resounding success. Ticket sales accounted for $47,000 with additional donations ($5,000 coming from Elvis), pushing the total take to over $60,000. Funding for the memorial was still well short of its target. Still, the electricity of Elvis had generated the jumpstart the campaign needed. In 1961, Hawaii Senator Daniel Inouye got legislation passed to secure another $150,000 in federal funds. Money began to flow from other sources. The combination of public funds and private donations (including $40,000 from Revelle raised through sale of model kits of the Arizona) reached the goal of $500,000 by September 1961 – just 5 months after the concert. The end of the year completed construction on the memorial.

The U.S.S. Arizona Memorial was officially dedicated on May 30, 1962. Elvis certainly took pride in his role in building a permanent memorial to the crew of the Arizona. He made several visits to the site on subsequent trips to Hawaii. The memorial has reached its own iconic status and welcomes 1.5 million visitors a year.

Elvis did not forget the Arizona, and the Navy did not forget Elvis. When Elvis passed away in 1977, the Navy showed its gratitude by placing a wreath for him at the U.S.S. Arizona Memorial.

Much of today’s upkeep comes from the fundraising of the American Veteran (AMVETS), a veteran’s service organization that helped to secure around $250,000 in total for the memorial during the 1950s. The organization is responsible for the upkeep of the white marble wall inscribed with the names of the men who perished aboard the U.S.S. Arizona. In 1983, and again in 2014, AMVETS raised funds needed to replace the deteriorating Wall of Remembrance.