“My Facebook Page/Group was shut down.”

“My credit card processor shut me off.”

“Google won’t accept my AdWords budget.”

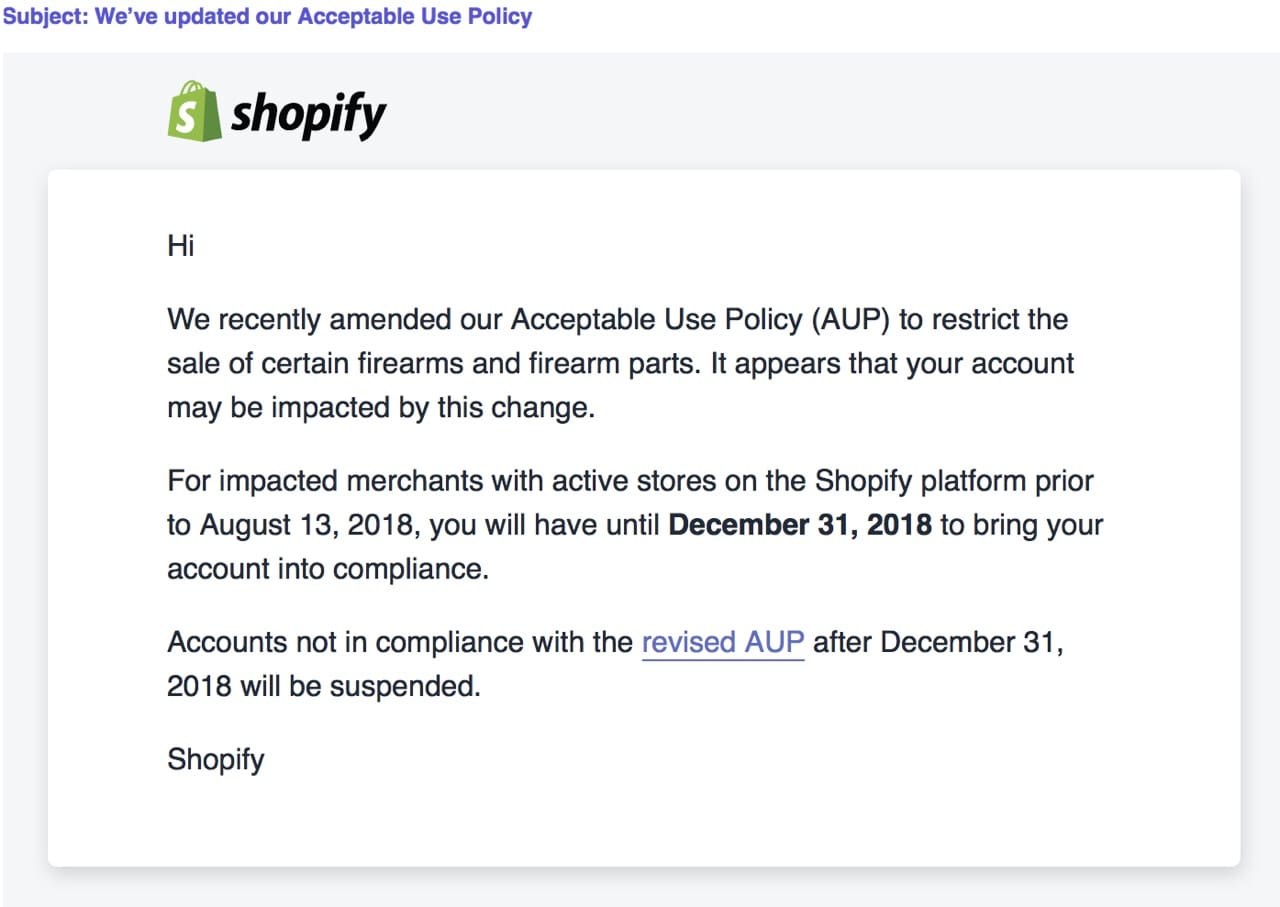

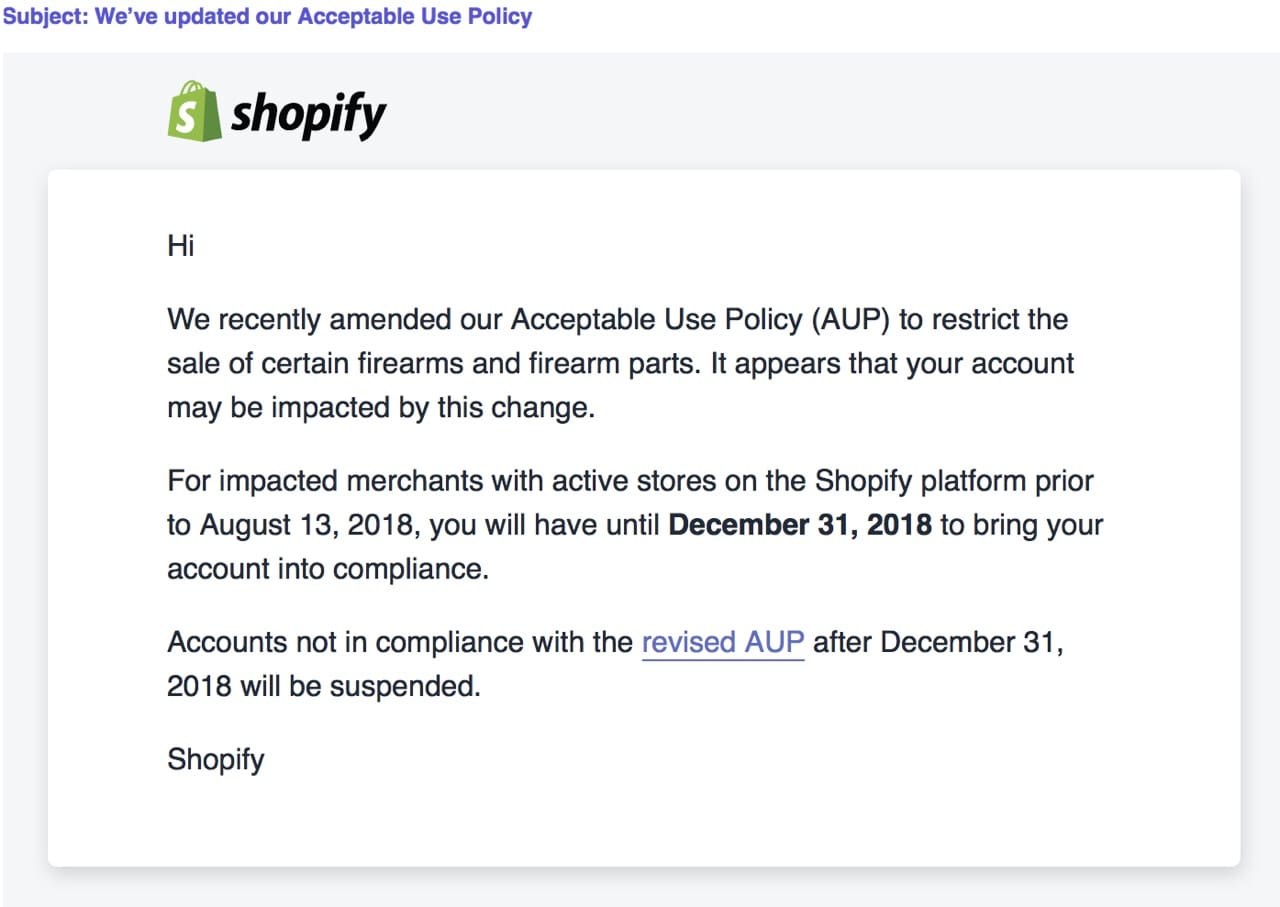

“Shopify modified their Acceptable Use Policy and turned off my website.”

All of these are common complaints we see online every day from businesses operating in and around the Shooting, Hunting, Outdoor, and Tactical (SHOT) market – particularly when there’s tools like firearms, knives, and accessories involved. What was once a wide open ‘Wild Wild West’ of the market, is now an increasingly controlled World Wide Web of regulations, rules, and policies. Not many of which are designed to support the SHOT market. Most of them are designed to mitigate liability and risk for the partners and vendors involved. And now that risk mitigation is being wielded to target the SHOT Market.

Shopify’s Acceptable Use Policy (AUP) update last week is not the first shot of the war. It is one more shot in another battle in a long series of battles. Since the beginning of commerce on the internet we’ve seen this. If it’s not the SHOT market, it’s drug-related content, 3D CAD files (Defense Distributed), the adult industry (watch the movie ‘Middle Men’), and a myriad of other targets.

Doing business online in the SHOT is achievable, but owners/operators need to be realistic and take an approach to mitigate our risk. In the chain of vendors and service providers needed to successfully operate a 2A business, all of them carry inherent risk. Hosts, credit card processors, software licenses, service providers: all of them can change their policy at any time and have a negative effect on your ability to do online business. These policy changes may not be because they dislike us, our products, or our customers. Rather, it may be a requirement of their financial institutions – banks, lenders, processors, investors, their insurance providers – many of whom dislike the inherent risk associated with commerce in 2A, or their leadership or board members – some of whom may push personal agendas in the course of their role, amongst many other factors.

For that reason, it’s important to have these conversations with our providers. Be upfront about our business with our online resources. Let them know what our businesses do, with whom, and what steps we’ve taken to mitigate their risk (your resources, your customers), and our risk – as a business owner/operator. And, ask them the tough questions: “Do you support my business – the legal sale of products in the 2A space?” If the answer is no – move on. If the answer is yes, ask them how they plan to deal with external pressure to exit the space. Ask them how they plan to notify us in the event they are ‘required’ to change their policies/terms that may negatively affect our business’ ability to conduct commerce online.

These questions and relationships can happen at many different levels in the spectrum of online business, depending on our approach to doing SHOT business online. For most of our businesses, this falls into one of three solutions:

Full Custom Development

Working with your team and that of a developer, payment and processor solutions, hosting, homegrown or licensed cart and other software, and likely a suite of marketing and management tools. This option provides the most flexibility for a SHOT business that has the business to support the diverse group of resources required to make it work.

Full Custom is often the most expensive and time intensive but allows for an environment where overall risk is greatly reduced by spreading it across multiple vendors and resources: if one fails, it can often be replaced with another that supports our industry. Solutions like this are perfect for companies looking to both mitigate risk, as well as having a diverse set of business rules and requirements.

Hosted Solutions

Yes: there are hosted solutions alternatives to Shopify that ARE SHOT and 2A friendly, including huge companies with stronger platforms and capabilities than Shopify has ever had. These SaaS (Software as a Service) companies provide nearly a one-stop-shop environment: pay the fee, plug-in your products, start doing business. Yes, that’s a generalization, but time-to-commerce is reduced significantly working with one of these providers.

With Hosted Solutions we operate in their environment, they maintain the hosting, software, and vendors required for us to do business. Using their services or outside resources, you skin the look and feel of the site and add your content and you’re off! From a risk perspective, like Shopify, some of these services can be an all-or-nothing endeavor: if they change a policy your business could be shut down.

It’s imperative, therefore, to have the discussion about policy changes up front with a Hosted Solution provider – will they work with you in the event of a policy change? Can they or will they explore other resource options to support you if, for example, their credit card processor was the weak link and opted out of 2A business? Again – there are some fantastic options out there but approach any relationship with a Hosted Solution provider with your eyes wide open and have a plan for contingencies. These solutions are optimal for brands looking for near-turn-key ecommerce solutions, preferably for brands not selling firearms, weapons, or accessories – soft goods and non-gun parts are a good fit.

DIY Solutions

If you’re good with rolling up your sleeves and terms like ‘CSS’ and ‘API’ don’t scare you, then a DIY solution might be for you. Or, if you can figure out how to navigate some of the online basics of buying a domain, finding a host, and installing plugins, it’s not hard to roll-your-own with little to no help. There’s a number of free shopping carts available. Some requiring little configuration, the others a degree in computer sciences. Depending on your skill and risk level, these could be a good fit for you, but often would be better suited to engaging a developer for a custom project.

Other options may be simpler and easier. One of the most expedient methods is to use WordPress – a widely adopted blog software – in combination with a cart plugin. WordPress powers a claimed 31% of the internet – and it’s a believable claim: their software is everywhere. Over time, companies have built a significant number of plugins to extend the capability of WordPress, including shopping cart software. These shopping cart plugins are available as free, licensed, and hosted options – all ‘plugging into’ the WordPress environment to allow you to operate an online store. Using the easy WordPress interface and finding a place to host your website are relatively straightforward processes. Adding in payment processors, fulfillment providers and other plugins can be a bit trickier, but generally achievable for most.

Building one of these sites takes some time and it opens us to some risk: If your cart plugin is dependent on a specific payment gateway, or any other service/capability, plugin or extension and that provider changes their policy, your business could be at risk. Therefore, a shopping cart plugin with a wide array of options to fulfill these roles and needs is advisable and will help mitigate your risk. Additionally, there’s the possibility of WordPress changing their policies and terms, and though that could be difficult to enforce with the broad proliferation of their software, it could happen. These solutions may allow you to diversify risk across more components and may cost less than a full custom solution or hosted solution, but they add time and resource requirements.

There is a solution for everyone. The options above can and do work. We work with iterations of them every day. Because we, as an industry, are not done or going away. They can’t push us out or shut us down. Using one of the solutions above, or a combination of them, can help mitigate our risk. Having a plan, however, will help further reduce our risk and ensure we’re ready for contingencies. Managing our risk with a plan isn’t a suggestion, it’s a requirement for a smart business owner. They have and will continue to make it harder and more difficult for us. More policies will change, likely not in our favor. More providers will fail us. But we’ve got a plan.

By N Hoffman.