We have joined Mammoth Nation! If you haven’t heard, Mammoth Nation is America’s Conservative Discount Marketplace. They’re a membership-based online shopping platform with an emphasis on American-owned businesses and/or products made in America while also openly supporting Conservative Candidates and Causes. Members receive great discounts from a growing list of companies that share our values.

Check them out at www.mammothnation.com

Support our new affiliate and many other great American companies by joining Mammoth Nation today!

Save 30% on membership fees by using promo code 215GEAR30

Or use this link mammothnation.com/join-mammoth-nation

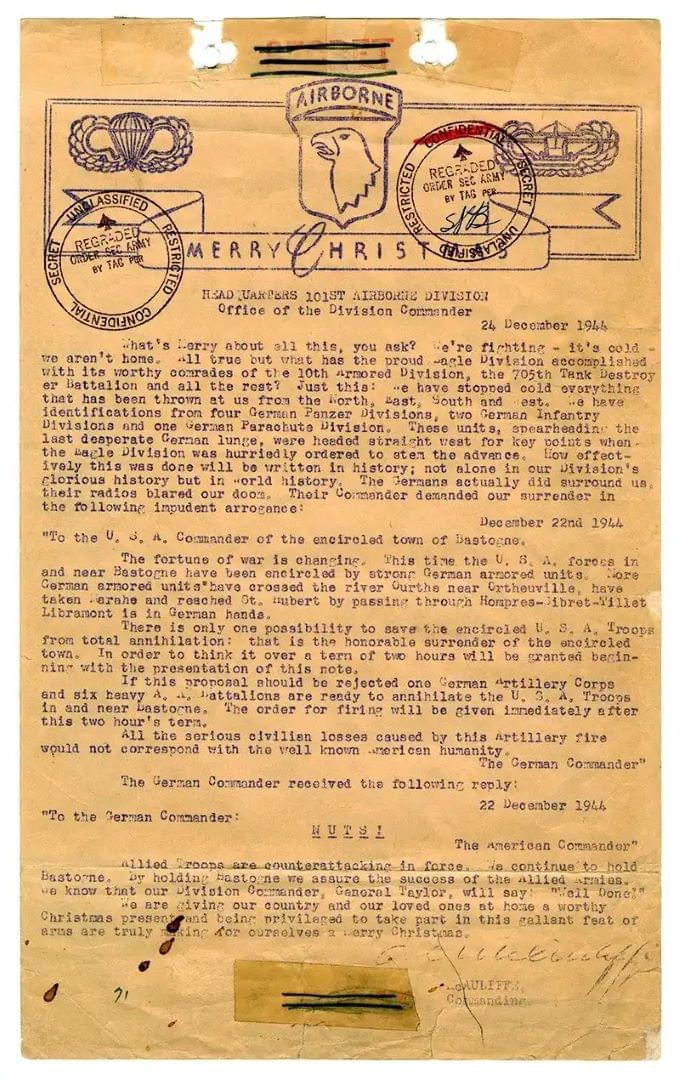

December 22 1944 – Encircled by German forces at the Battle of the Bulge, the 101st Airborne Division, under acting commander Brigadier General McAuliffe received a message from German General Heinrich Freiherr von Lüttwitz delivered under flag of truce.

To the U.S.A. Commander of the encircled town of Bastogne.

The fortune of war is changing. This time the U.S.A. forces in and near Bastogne have been encircled by strong German armored units. More German armored units have crossed the river Our near Ortheuville, have taken Marche and reached St. Hubert by passing through Hompre-Sibret-Tillet. Libramont is in German hands.

There is only one possibility to save the encircled U.S.A. troops from total annihilation: that is the honorable surrender of the encircled town. In order to think it over a term of two hours will be granted beginning with the presentation of this note.

If this proposal should be rejected one German Artillery Corps and six heavy A. A. Battalions are ready to annihilate the U.S.A. troops in and near Bastogne. The order for firing will be given immediately after this two hours term.

All the serious civilian losses caused by this artillery fire would not correspond with the well-known American humanity.

His response was perfect.

To the German Commander.

NUTS!

The American Commander

Believe it or not, the story gets even better. Upon hearing the reply, the German envoy was confused, not understanding the context.

An American Colonel quickly set the German straight, “If you don’t understand what ‘Nuts’ means, in plain English it is the same as ‘Go to hell.’ And I will tell you something else – if you continue to attack we will kill every goddam German that tries to break into this city.”

Massif’s Elements line of FR clothing was some of the first gear on the market for military use which combined performance with protection from flame threats. In fact, this COTS solution was in use by select military aircrews before operations in the Middle East drove widespread adoption of the technology. Massif has launched a military version of the bib with new features.

Designed to keep you safe and warm, the Elements Bib incorporates a triple-layer, 4-way stretch Softshell flame-resistant fabric which sheds wind and rain. It features a fleece interior and an abrasion resistant exterior. The Battleshield XO FR fabric features Gore® (FR) stretch technology.

The bib design is cut high to eliminate skin exposure when worn with a jacket. In addition to above-the-knee-length zips to facilitate donning and doffing, there are two side entry pockets at the chest. There is a two-way zipper down the front and take up tabs at the waist ensure a snug fit to protect from flame threats. In addition to the two zippered handwarmer pockets at the waist, there are also cargo pockets on either thigh. Finally, both the knee and hem are reinforced with 330D Cordura.

Offered in OCP in sizes XS-3XL.

www.massif.com/elements-bib-military

This week the Royal Canadian Mounted Police issued an RFI for Pistol Modernization to industry regarding a new sidearm to replace the currently issued Smith & Wesson 5946.

General Requirements

Determining that the current weapon has exceeded its life expectancy, they are looking for a modern design offering reduced trigger pull weight, various frame sizes, and a reduction in overall weight as well as the ability mount both a weapon light and Red Dot Sight (RDS).

While they are sticking with 9mm, the RCMP desires a mechanically locked, recoil-operated, striker-fired semi-automatic pistol with polymer frame which can accommodate at least three grip sizes. The pistol must also be matte black, corrosion resistant, and equipped with iron backup sights in addition to the RDS.

While the pistol must have no external manual safety levers, grip safeties, and push-button safeties, it must fireable without a magazine installed.

This requirement is fairly unique, each pistol must come with a ceremonial lanyard loop that can be attached to the pistol magazine’s base plate. Additionally, the slide must be steel.

Ancillaries

a) Red Dot Sight (RDS)

b) Weapon Light

c) Carrying Case

d) Holsters (Regular and Plain Clothes)

e) Three magazines per pistol

Dimensions

Dimension requirements are a maximum length of 190.5 mm and a maximum overall height of 140 mm with the magazine and any MRDS removed along with a maximum length of 190.5 mm (7.50 inches) when measured from the muzzle to the rear of the beavertail. The pistol barrel must have a minimum length of 99 mm (3.9 inches) and a maximum length of 108 mm (4.25 inches). It must not weigh more than a maximum of 808 grams (28.5 oz) when the magazine is empty, and no accessories are attached.

Accuracy

As far as accuracy goes, the requirement stipulates that the pistol must be capable of shooting a 15.25 cm (6 inch) grouping from 25 m (27.34 yards) away.

Reliability

The service life on major components (i.e. frame, slide and barrel) that exceeds 20,000 rounds and the RDS must have a minimum warranty period of two (2) years. Additionally, the LED weapon light must have a minimum warranty period of two (2) years on switches and electronic components and the holster must have a minimum warranty period of five (5) years.

https://canadabuys.canada.ca/en/tender-opportunities/tender-notice/pw-bm-039-28894

DroneShield Ltd (ASX:DRO) (DroneShield or the Company) is pleased to advise it has received an all-time record purchase order for approximately A$11 million.

The order includes several different types of DroneShield counterdrone/C-UAS equipment. A substantial part of the order is expected to be delivered shortly, with the remainder in late March 2023. A$11 million corresponds to the combined value of both phases of the project. Payment for each batch is expected to be received within a month of each delivery. The proceeds are expected to be received across March and June 2023 quarters.

DroneShield CEO, Oleg Vornik, commented: “With this transformational next step in DroneShield’s growth, and as the counterdrone industry continues to rapidly grow, we look forward to rapidly fulfilling this contract.”

“From the start of the Company 7 years ago, DroneShield has demonstrated a consistent progression, first by building and then refining its product suite along with global distributor network, then moving to customer demos, followed by initial smaller sales, repeat $1m+ sales, and now moving into $10m+ sales territory.”

“Over last 24 months, we have made a significant investment in scaling our operations, to ensure we continue to meet delivery expectations of our customers as we rapidly scale up.”

Image: DroneGun MKIII

This large contract win follows a number of other recent wins for DroneShield in last couple of months. Other significant advancements include recommendation by the Joint Counter-small Unmanned Aircraft Systems Office (JCO) as part of the SAIC Team’s offering for deployment of its Counter-UAS as a Service across US DoD, a SBIR project awarded by US DoD with partner Quantum Research International, the first US airport deployment among other deployments across US, European and other Government customers, and appointment to the Australian Department of Defence Intelligence, Surveillance, Reconnaissance and Electronic Warfare Standing Offer Panel.

Additionally, last month, DroneShield welcomed a A$3.7 million investment from Epirus Inc, a high-growth U.S. defense technology company developing software-defined directed energy systems that enable unprecedented counter-electronics effects and power management solutions to optimize power efficiency in defense and commercial applications. This includes the Leonidas solid-state, software-defined high-power microwave (HPM) technology to enable unmatched counter-electronics effects for a range of use cases. Additional information about Epirus can be found at https://www.epirusinc.com. Epirus was founded in California in 2018 and has raised approximately US$300 million (approximately A$450 million) in funding since inception.

DUKE FIELD, Fla. —

Aircrews from the Air Force Reserve’s 711th Special Operations Squadron departed the Duke Field flightline Dec. 15, 2022, in four C-145A Combat Coyote aircraft for the last time after 10 years of service to Air Force Special Operations Command.

When the aircraft returned, aviators, loadmasters, and ground crew alike all gathered to respectfully mark the end of an era.

The Combat Coyote’s landed in sequence and proceeded in tight formation down the taxiiway as if to offer one final show for the small group of awaiting spectators.

“There weren’t many other aircraft in the Air Force like this one,” said retired Chief Master Sgt. Bobby Barton, former senior enlisted leader of the 919th Special Operations Group. “These guys loved this airplane, it really stood out from the crowd.”

The 919th Special Operations Wing began utilizing the Combat Coyote in 2012. Combat Aviation Advisors from the 711th SOS used the aircraft to maintain proficiency prior to instructing partner nation aircrew on a wide range of advanced aviation tactics. Instructors from the 5th Special Operations Squadron Detachment 1 at Duke Field trained U.S. Air Force pilots on the aircraft for Air Force Special Operations Command.

Although it was not used for overseas deployments in recent years, the Combat Coyote’s provided a tactical mobility advantage to missions downrange when they were initially purchased by the command. They could make short landings and takeoffs, ideal for rural, undeveloped airfields and cargo delivery to forward operating bases.

“Today’s flight was a little bitter sweet,” said Maj. Kristoffer Williams, 711th SOS chief of safety. “It’s been a great aircraft to fly, the Wolfhound was good to us while it lasted.”

The 919th SOW was the last wing operating the airframe, officially retiring it from the U.S. Air Force. Citizen Air Commandos and their families gathered on the flightline to watch the planes land and congratulate pilots on the final flight.

“We put a lot of blood, sweat and tears into this airframe,” said Williams. “We learned to appreciate it, but it’s time to move on to the next aircraft.”

The wing has a historical precedent of adapting to the needs of the Air Force. The 919th SOW previously retired the beloved AC-130H Spectre and the MC-130E Combat Talon I. As it has in years past, the wing is prepared to transform to meet the future needs of Air Force Special Operations Command.

“The only constant in the Air Force is change,” said Barton. “The people that flew the C-145 enjoyed it. It was a nice aircraft to have for a while, but I’m looking forward to the next one.”

By Senior Airman Dylan Gentile, 919th Special Operations Wing

Saab has received orders from the Latvian Ministry of Defence for ammunition for the Carl-Gustaf® recoilless rifle. The order value is approximately SEK 185 million.

The order is placed within a framework agreement between Saab and the Swedish Defence Materiel Administration (FMV) which enables Latvia to place orders for Carl-Gustaf M4 weapons and ammunition over a ten-year period.

“We are pleased to continue delivering our world-class ground combat capabilities to Latvia. This order will support the Latvian National Armed Forces’ ability to meet a wide range of challenges on the modern battlefield,” says Görgen Johansson, head of Saab’s business area Dynamics.

Proven to deliver results on the battlefield, the Carl-Gustaf provides the effectiveness soldiers need. The wide range of ammunition types available for Carl-Gustaf makes it flexible and able to handle any situation on the battlefield, whether it is to destroy an armoured vehicle or structure, or illuminating the battlefield during night-time operations.