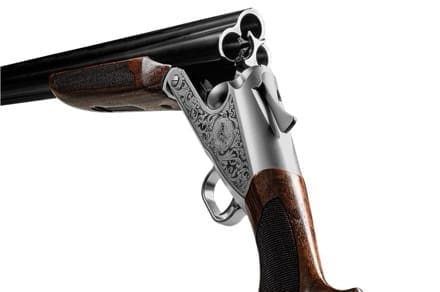

Summerville, SC – American Tactical proudly announces the arrival of the Cavalry 3B™ Triple Barrel Shotgun, a break-open 12-gauge that redefines expectations with its striking three-barrel configuration and refined aesthetic. Designed to be both a functional workhorse and a standout centerpiece, the Cavalry 3B delivers innovation, reliability, and undeniable “wow” factor in one commanding platform.

A Design That Breaks the Mold

The Cavalry 3B isn’t your typical shotgun. Featuring an 18.5-inch or 20-inch triple-barrel configuration, this uniquely engineered firearm pairs bold performance with timeless styling. Elegant walnut furniture complements a black or silver receiver adorned with intricate scroll engraving, creating a classic look with a modern edge.

As a break-open action shotgun, the 3B maintains mechanical simplicity and rugged durability, all while offering an eye-catching profile that immediately distinguishes it from traditional single- or double-barrel designs. In addition, the Trigger Housing drops out for easy cleaning and maintenance.

Triple-Barrel Performance

Chambered in 12-gauge and capable of accepting up to 3½” Magnum shells, the Cavalry 3B offers exceptional versatility across a wide range of loads. Its preset firing sequence—Lower Right barrel first, followed by Left, then Top—provides three ready shots in a consistent, predictable cadence.

By combining triple-shot capability with the legendary reliability of a break-action system, the 3B eliminates the mechanical complexity of semi-automatic platforms while still delivering rapid follow-up shots when needed.

Built for Versatility and Comfort

?

Despite its formidable appearance, the Cavalry 3B is surprisingly balanced and manageable, weighing just 7 pounds with an overall length of 35.5 inches. Key features include:

• 5 Internal Choke Tubes (Full, Improved Modified, Modified, Improved Cylinder, Cylinder)

o Stevens 555 threading for compatibility

• Premium Recoil Pad to help mitigate felt recoil, especially with Magnum loads

• Green Fiber Optic Front Sight for enhanced visibility and rapid target acquisition

• Extractor System for reliable shell removal

• Steel Shot Rated for modern ammunition compatibility

• Sling Post and Swivel Stud included

The included choke selection allows shooters to fine-tune pattern spread for various applications, while the fiber optic sight ensures fast sight alignment in diverse lighting conditions.

Key Specifications

• Model: Cavalry 3B

• MPN: ATIGKOF123B18

• UPC: 810113111063

• Action: Break Open

• Gauge: 12

• Capacity: 3

• Chamber: 3.5”

• Barrel Length: 18.5” (Triple Barrel)

• Overall Length: 35.5”

• Weight: 7 lbs

• Length of Pull: 14.25”

• Sights: Green Fiber Optic Front

• Recoil Pad: Premium

• Chokes: 5 Included (F, IM, M, IC, C) – Stevens 555 Threading

• Shell Extraction: Extractor

• Steel Shot Rated: Yes

• Drilled & Tapped: No

• Fire Sequence: Lower Right ? Left ? Top

A True Conversation Starter

With an MSRP of $889.95, the American Tactical Cavalry 3B offers shooters and collectors a distinctive alternative in the 12-gauge market. Whether admired for its engineering ingenuity, demonstrated for its rapid three-shot sequence, or appreciated for its refined detailing, the 3B stands as both a functional firearm and a bold statement piece.

For more information, visit www.americantactical.us or contact your local American Tactical dealer.