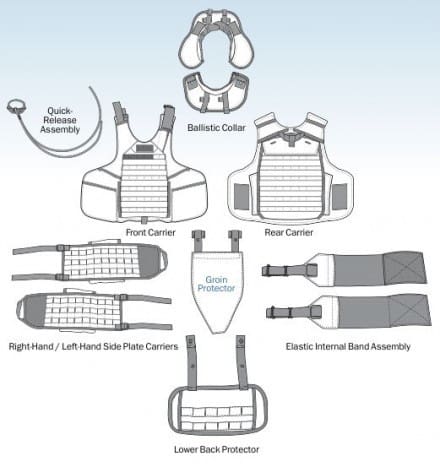

Yesterday, tt a ceremony in their factory in McKee, Kentucky, BAE Systems celebrated the production of their 15 Millionth MOLLE component. In fact, about 10 million of those components originated at that very facility. It’s hard to believe but MOLLE itself is almost 15 years old. Developed in 1997 in conjunction with the US Army’s Natick Soldier Systems Center, MOdular Lightweight Load carrying Equipment or MOLLE is a system of individual load carrying components used primarily by the US Army. The heart of the system is the Pouch Attachment Ladder System (PALS) standard that allows the equipment to be tailored to the mission by configuring various vests, packs and armor carriers or “platforms”, as they are known, with specialized pockets and pouches to carry equipment. The beauty of MOLLE is that it is spirally developed. As new technologies and weapons are fielded, MOLLE can adapt by adding or dropping pouches and platforms. Not only has this happened several times over the life of the program but it has been fielded in no-less-than four camouflage patterns: Woodland, 3-Color Desert, UCP, and OCP. Associated systems such as the USMC’s ILBE, USAF DF-LCS, and SOCOM’s SOF-LCS as well as individual components have been produced in even more styles and colorways, but have all relied on PALS.

The original MOLLE Core Rifleman set incorporated a rucksack, load bearing vest, and pouches and included the so-called “probe and socket,” a quick-release between the pack frame and waist belt that might have been a little ahead of its time. The currently issued system includes a one-size-fits-all load bearing vest, Pack with and a fixed waist belt and a Tactical Assault Panel (TAP).

On hand at the event was Don Dutton, Vice President of BAE Systems’ Protection Systems. He related, “The MOLLE system provides users with a completely customizable set of equipment which allows for readiness, mobility and efficiency of the warfighter, reaching a milestone such as the production of 15 million components, is an exceptional achievement for BAE Systems and its employees to achieve. Our employees come to work each day knowing that the work they do, is helping our warfighters overseas.â€

Also attending the celebration were Representative Marie Rader (R-Kentucky), U.S. Congressman, Harold Rogers (R-Kentucky), Major General Ed Tonini, The Adjutant General for the Kentucky National Guard and Sergeant Major Charles Williams of PM Soldier Protection & Individual Equipment.

“Job well done to the fine BAE Systems employees hard at work in Jackson County. This is a remarkable achievement,†said Congressman Hal Rogers. “Not only are these McKee sewing technicians making our region proud through exceptional craftsmanship, but they’re helping our warfighters stay well equipped and battle-ready with light-weight, adjustable gear. This work not only creates good paying jobs in southern and eastern Kentucky, but builds the security of our nation.â€

www.baesystems.com