> Growing up in rural North Carolina, McRae Industries founder Branson McRae had big dreams for the future. He went on to become a world leader in manufacturing military footwear.

Mount Gilead, NC, sits at the foot of the Uwharries, North America’s oldest mountain range. With a population of just over 1,000, this Montgomery County community, located an hour east of Charlotte, is small-town America at its best: plenty of fresh air, picturesque charm, and peaceful living all around.

Just outside town, McRae Industries, Inc. – a world-renowned footwear manufacturer – has been a legendary mainstay for six decades.

Small-town charm: Mount Gilead sprung up in the late 19th century.

McRae Industries founder Branson Jackson McRae, born in 1920, grew up in Mount Gilead, the third of six children. Branson’s stalwart work ethic was gleaned from his father, James McRae, a farmer and descendent of Scottish immigrants.

The will to succeed: Branson on the family farm in Mount Gilead,1930.

Self-described as an “opportunist and a dreamer,” Branson contemplated his future while working on the family farm. “I’d have a mule in the cotton patch and would be seeing all the nice automobiles drive by,” he once said. “I would think, will I ever have one of them?”

After graduating from Mount Gilead High School in 1937, he set out immediately for a full-time job.

Building ships, houses, and a skating rink

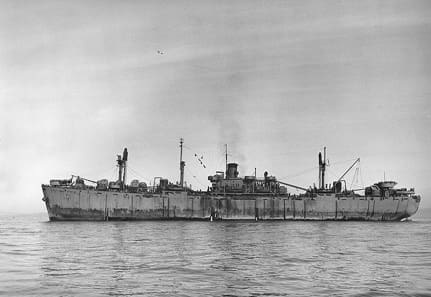

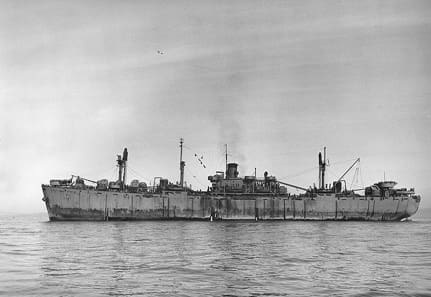

As World War II approached, Branson relocated to Wilmington, NC, to build Liberty ships – cargo vessels that were a frequent target of German U-boats.

While living in Wilmington, he met and married his future wife and spirited soulmate, Lorraine Hamilton, with whom he had four children: Gail, Sandra, Gary, and Jim.

“In the war days, job security for Liberty builders was a given, Branson’s son Gary says. “The Germans sunk the ships so quickly more were always needed.”

Branson’s first job: Building Liberty ships for World War II combat.

When the war ended, Branson joined with brothers JC, Philip, and Finley to launch the McRae Brothers Manufacturing Company, a home construction business based in Mount Gilead. Business boomed, but Branson was always on the lookout for fresh opportunities.

In 1956, he purchased an abandoned brick school building in Wadeville, just a few miles northeast of town, where his daughter Gail had attended elementary school. There, he and Lorraine opened a skating rink, readily building a popular new business.

Starting a shoe company

Two years later, another prospect loomed. A business group from New York visited Mount Gilead with the vision of opening a shoe factory there. Although the plan was abandoned, Branson sensed the opportunity – and seized it.

“Dad was laser focused on starting a factory in the old schoolhouse,” son Gary says. “At the age of 40, he threw caution to the wind. He knew nothing about footwear, but he was confident he could learn and succeed.” The new business, Gro-Rite Shoe Company Inc., was soon manufacturing children’s footwear for such industry leaders as Kinney Shoes.

A new business begins: The Wadeville schoolhouse, circa 1967.

To start his company, Branson invested $100,000 in cash and assets in exchange for a third of the new company’s stock, selling the remaining two-thirds’ interest to local investors. With a total $300,000 investment, Gro-Rite was “woefully underfinanced,” son Jim says. “Profits were slim, but Dad persevered.”

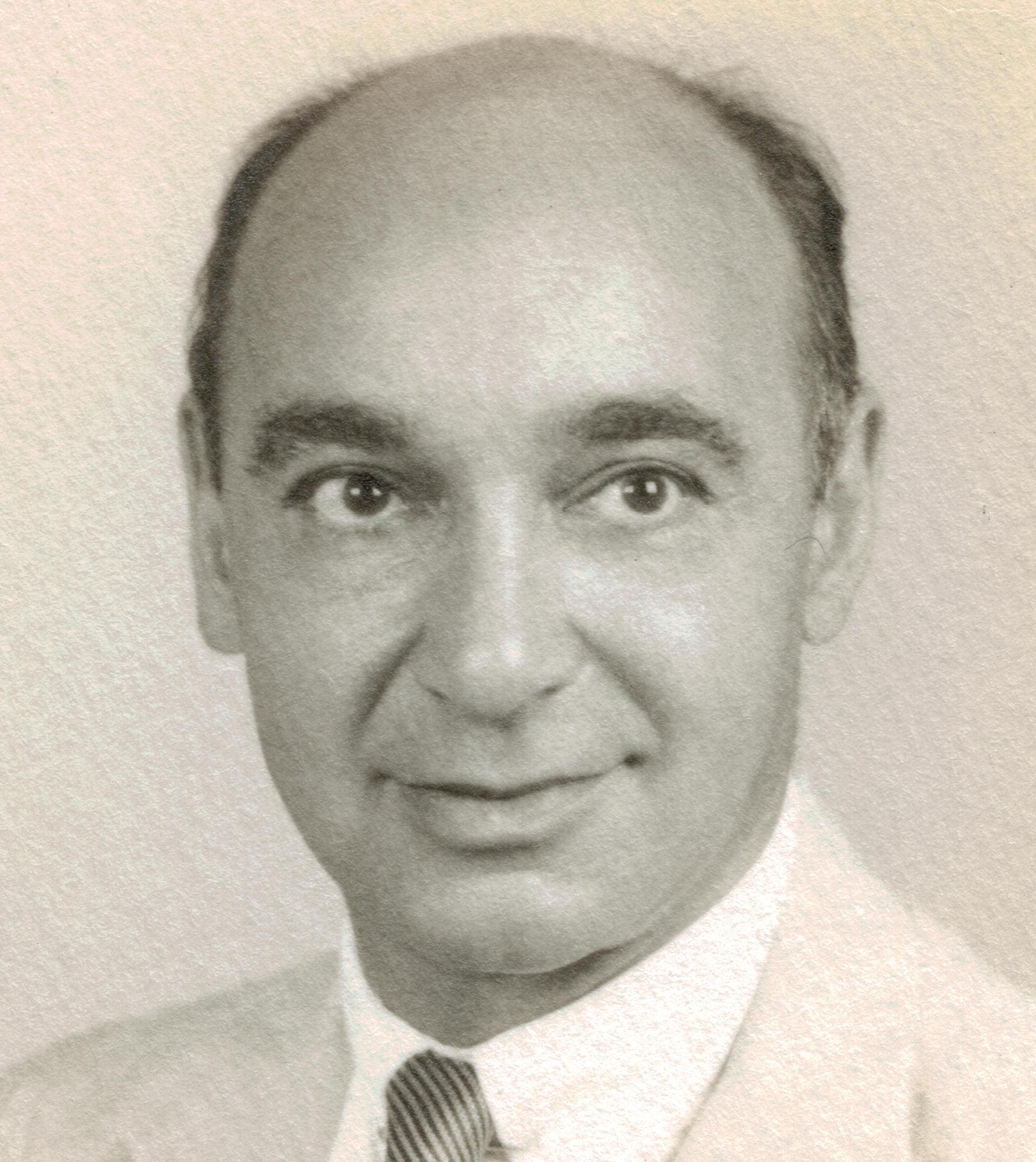

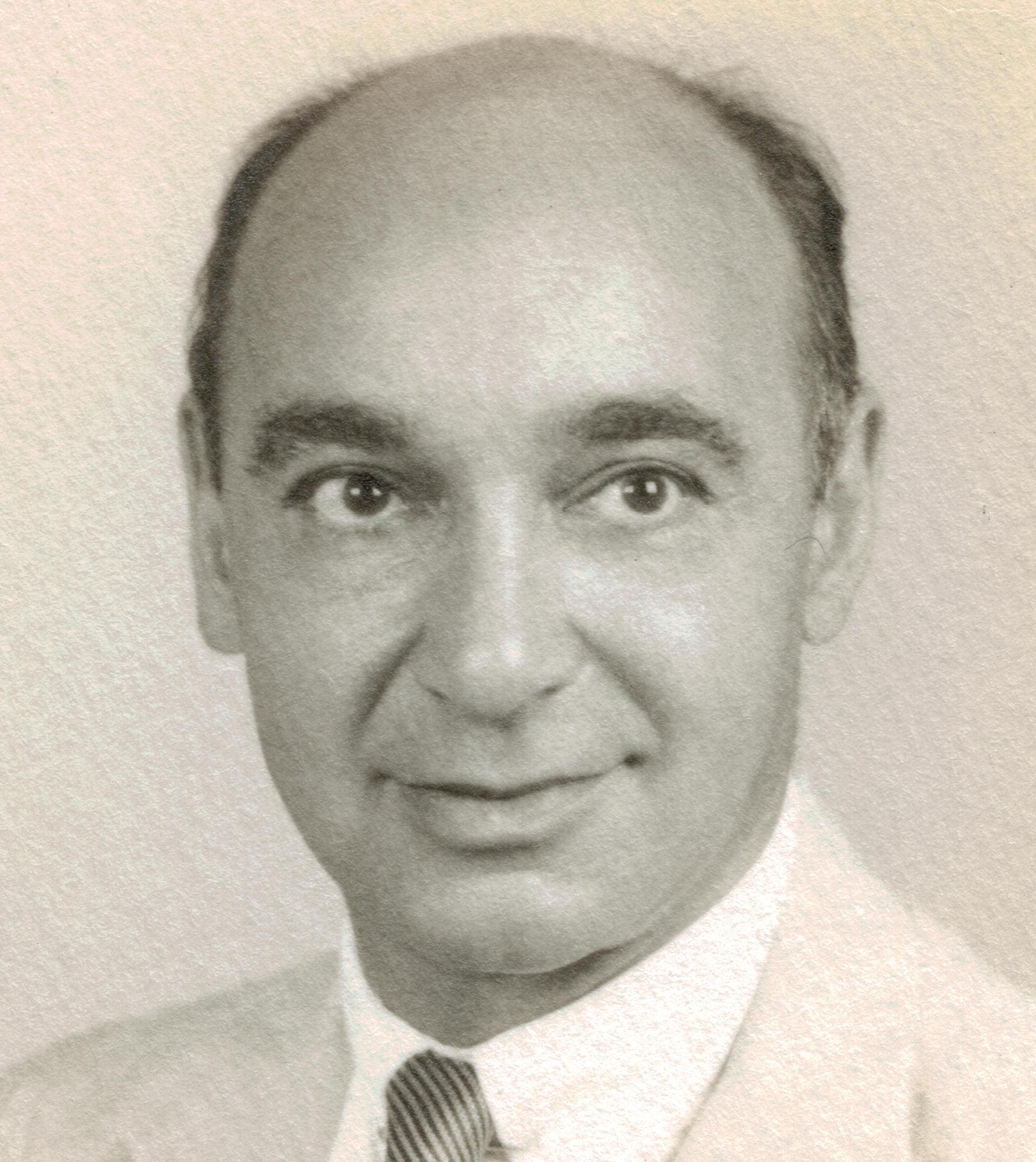

Shoemaker mentor: Heinz Rollman taught Branson his patented method.

Learning the craft

Branson’s mentor in his new business venture was Heinz Rollman, a third-generation, multimillionaire shoemaker. Heinz had fled Nazi Germany in 1939 and relocated his company, RoSearch Inc., to Waynesville, NC. He and his partners operated 72 shoe factories worldwide and invented “Process 82,” a patented method of making shoes using vulcanized rubber. Instead of stitching together the upper and lower parts of the shoe, the process “cooks” the two together, creating a highly durable construction.

“People who won’t give up, no matter what difficulties they encounter, those kinds of people I admire and respect more than money.”

– Heinz Rollman, founder of RoSearch Inc., and mentor to Branson McRae

“Heinz could see that my father, though lacking in funds and knowledge of the shoemaking business, was sincere, ambitious, and uncommonly determined,” Gary says. “He granted Dad a license for Process 82, and Gro-Rite became the first company in the U.S. to receive a patent for vulcanizing children’s shoes.”

Branson renovated the school building’s 12,000 square feet of floor space – and added another 3,000 feet to build a rubber mill. He hired more than 100 Montgomery County workers and put them through a vigorous training with RoSearch experts. Branson also purchased the machinery to cut, sew, and prepare leather for vulcanizing.

Gro-Rite’s unconditional guarantee: “A new pair of shoes free if the soles wear out or the counters break down before the shoe is outgrown.”

Each step of construction followed the Rollman family’s carefully crafted procedures. The result? A faster construction process, elimination of several steps required in conventional shoe manufacturing, and a shoe that stands up to water.

Six years after Gro-Rite’s launch, America’s involvement in the Vietnam War was accelerating. American soldiers needed resilient footwear – boots that outlasted the treacherous conditions of Southeast Asia. The federal government took notice of Gro-Rite’s vulcanizing technique and asked the company to bid on a contract for combat boot construction. Branson responded, the contract was awarded, and destiny took a new turn.