PEARL is a weapon mounted system that localizes in real time, small arms fire based on sound waves generated by the shot.

Although it is mounted here to a carbine, it can also be mounted to a vehicle, mast, or directly to a building.

PEARL is a weapon mounted system that localizes in real time, small arms fire based on sound waves generated by the shot.

Although it is mounted here to a carbine, it can also be mounted to a vehicle, mast, or directly to a building.

Know as Taiga in Europe and Torraka in the US, this Swedish clothing company offers some great cold weather options. But one of their newer items at DSEi were these pants designed for Swedish Police.

You’ll notice the Grey color and the fabric is not FR but rather no-melt, no-drip.

Sometimes at a trade show you zig instead of zag? and when I turned left instead of right on my last say at DSEi I ran smack dab into the Intelligent Textiles Limited stand and their Molliflex cables.

The lady in the stand read my badge aloud, “soldier systems” and as she did it I looked at what they were doing and replied?, “you’re right in my wheelhouse.” Turns out, this is the gem I was searching for at DSEi, that one product I didn’t expect to find, but has great potential.

They’ve done such a good job with their Molliflex cable, that you probably didn’t even notice it in the photo at first or maybe even second glance.

The cable is just 2mm thick and can be woven into PALS compatible platforms. Due to how things it is, pouches can be added over Molliflex. Molliflex lays flat even when folded for 90 degree turns. In fact, it can be folded over two million times before the internal connection is broken. Additionally, it is IP68 rated. The connector is a standard Glenair Mighty Mouse which is Nett Warrior compliant.

Attachments to devices include an Ejector QD plug and Hardpoint attachment plate.

It is rated for power at 5amps,<50voltsDC1 and data at USB 2.0, 480 Mbps.

The outer material is DWR coated nylons me available in Multicam, Coyote, Flecktarn, CADPAT, and Black.

Platatac had a lot going on in their small kiosk within the Edgar Brothers stand. You could consider Platatac a one-stop tactical shop in their own right, but Edgar Brothers is the conduit for this Australian into UK government sales.

One of those many items is the Platatac Tactical Trauma Shears, shown above next a PMAG for scale. They’re a bit shorter? than standard trauma shears.

Made from Stainless Steel, these shears feature a serrated lower cutting edge, subdued coloring and a P.P. Plastic handle (for the Autoclave 143 Degree C requirement).

Finally, the price is great at A$15.

This wedge at the front of the Brigantes booth demonstrated a breadth of soldier systems capabilities offers by Brigantes and was used extensively to walk DSEi visitors through a variety of options.

Manikins were set up for Mountain & Arctic Warfare as well as Jungle and Temeprate zones.

The fabrics are from Milliken and include Milliken TactX Stretch fabric in Multicam which is a durable base fabric for performance finishes and Milliken’s best-in-class printing and shade matching.

It is a lightweight 98% plain weave nylon with 2% spandex with a DWR (durable water repellent) finish. The elasticity of the fabric allows the wearer freedom of movement and gives more allowance in the action areas of the garment. The nylon face fabric offers great durability to the wearer who would be very often carrying and equipped with a heavy back pack and/or body armor plus the wearer will probably be carrying a weapon utilizing a harness/strap.

Additionally, it is highly breathable whilst at the same time providing a degree of weather protection. The garment can be used as part of a layering system or can be used as a stand-alone depending on the weather conditions. It’s a very tactile fabric and extremely pleasing and comfortable to wear.

Lantac® Dragon® DGN556B-WM, DGN300B-WM & DGN9mm-WM Muzzle Brakes with Dead Air® KEYMO™ mount for the Wolfman Suppressor.

For immediate release.

Lantac is pleased to announce that it has completed development of its latest range of Dragon Muzzle Brakes that features the Dead Air KEYMO mounting system for the Wolfman suppressor. Lantac’s range of Dragon muzzle brakes are industry leading products that fundamentally improve the way firearms function, reducing muzzle recoil to zero and giving shooters maximum muzzle control for fast and accurate follow up shots. The Dragon range of brakes are so effective that there is no ‘knock off’ from target and even full auto fire is possible with hugely improved accuracy.

Shooters can now enjoy advanced weapon control with the ability to mount the Dead Air Wolfman® KEYMO silencer to their firearms.

Dragon brakes are precision manufactured on Swiss lathes and machined from AISI4150 steel that is then hardened to 48-52Rc (Rockwell C) and QPQ (Quench Polish Quench) Nitrided to AMS2753D standards for enhanced corrosion resistance and improved lifespan.

The mount design is fully licensed from Dead Air, therefore customers suppressor warranty remains unaffected.

Ships with timing shim set.

Users should follow shooting guidance for the Wolfman as supplied by Dead Air.

Lantac recommends the use of semi-permanent thread locker Rocksett, sold separately.

These new muzzle brakes can be pinned and welded to 14.5’’ barrels to meet ATF 16’’ minimum barrel length requirements.

MSRP:

DGN556B-WM, DGN300B-WM, DGN9MM-WM: $142.99

Mechanical Specification:

Threads: ½-28 TPI (5.56x45MM/.223 & 9x19MM).

Threads: 5/8-24 (7.62x35MM, 300Blackout).

Weight: 3.68oz (104.3g) approx.

Dimensions: LENGTH:2.367’’ (6.01cm), DIAMETER, MOUNT 1.080’’ (2.74cm).

Fiber Laser marked for quality control.

Made in the USA.

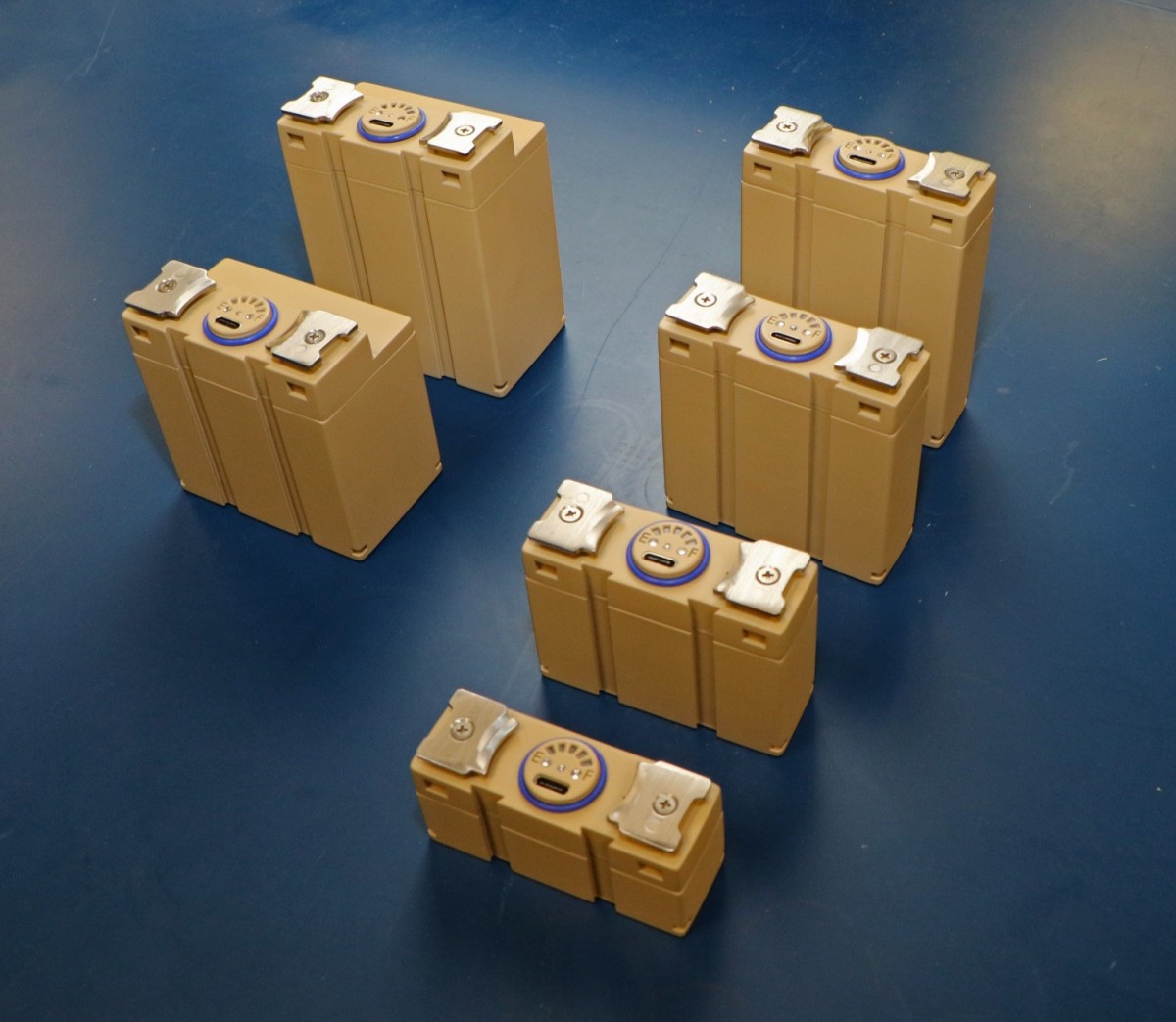

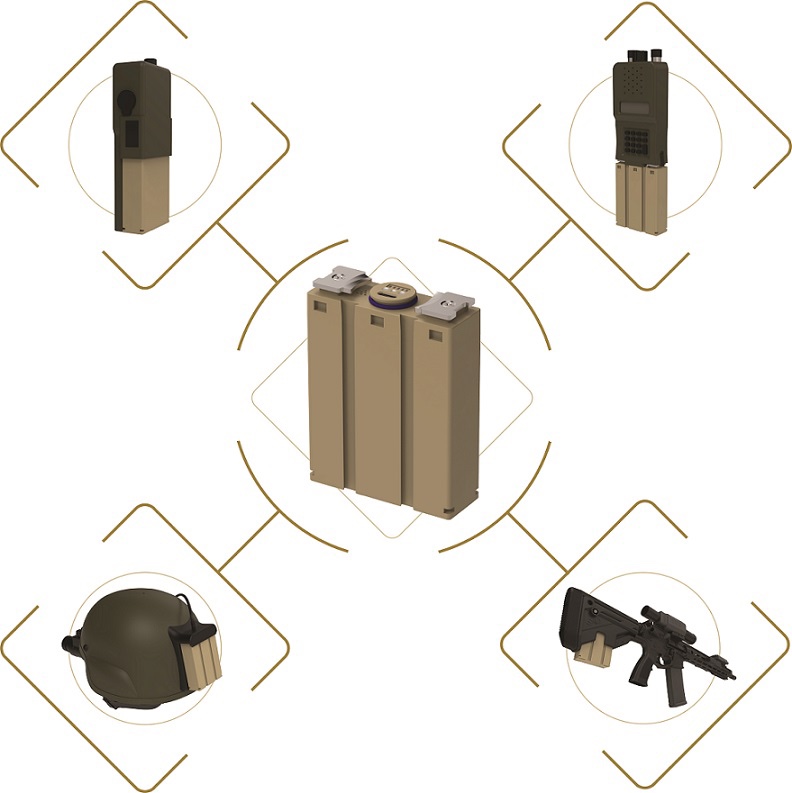

ABERDEEN PROVING GROUND, Md. — The Army is modernizing tactical power and reducing logistics costs by developing standardized batteries for Soldier-worn and handheld equipment such as radios, GPS, night-vision devices and weapons.

Army Futures Command (AFC) engineers are leading the project to deliver eight sizes of batteries that share a common mechanical and electrical interface — the key to unlocking interoperability.

The Small Tactical Universal Battery (STUB) is the Army’s latest approach to develop a standard family of batteries, according to Dr. Nathan Sharpes, a research mechanical engineer with the Command, Control, Communications, Computers, Cyber, Intelligence, Surveillance and Reconnaissance (C5ISR) Center — a component of AFC’s Combat Capabilities Development Command (DEVCOM).

“Now is an opportune time to standardize power sources as the Army is prioritizing modernization and fielding electronics with greater capabilities requiring more energy than current systems,” Sharpes said.

The C5ISR Center is leading the program that will benefit Soldiers, the acquisition community, logistics personnel and industry, Sharpes said. The goal is to avoid the current model of fielding a proprietary battery for each piece of gear as technology developers have historically delivered unique batteries for new capabilities.

Each battery size provides a different amount of energy, from which Soldiers could choose, depending on their mission needs. This interoperable battery system will seamlessly deliver the correct voltage and power level needs to any device.

“Currently when a Soldier is on a mission carrying five different pieces of gear that each have a unique battery form factor, along with spares, that’s extra weight and items to keep track of,” Sharpes said. “With this family of interoperable batteries, Soldiers will see benefits cognitively and physically.

“Any battery in the STUB family will be able to attach to any device designed for it because of the standard interface. We’re also incorporating eight attachment methods — such as slide on, clip in and twist on — so devices can use the universal battery in different ways. Soldiers can focus more on their missions and less on which types of batteries and how many of each to carry.”

Standardization also alleviates the burden of battery design from manufacturers of handheld electronics. As industry develops new C5ISR technologies, they will be able to concentrate on core competency areas while adhering to the already approved universal-battery specifications. All vendors would follow the same battery guidelines, Sharpes said.

The new standard universal-battery sizes will also simplify logistics and reduce supply chain costs, as the Army will be able to move away from procuring, storing, testing and shipping a wide array of unique batteries required for each piece of Soldier-carried equipment, Sharpes said.

The C5ISR Center’s STUB initiative follows in the footsteps of the Army’s development of the thin, flexible Conformal Wearable Battery (CWB) that Soldiers wear on their vests as a central power source for wearable electronic devices, according to Christopher Hurley, chief of the Center’s Tactical Power Branch.

The CWB development aimed to reduce the number of battery types needed by enabling a single power source to provide extended runtime to select pieces of kit. Current Army research would enable equipment to use smaller STUB batteries when not connected to the CWB.

“The end result is an overall lighter and more energy dense Soldier kit,” Hurley said. “The C5ISR Center is working across Army organizations to create battery standards and specifications. These efforts will meet the demands of the numerous pieces of equipment a Soldier uses and the diverse operating environments in which they conduct missions.”

——————-

The C5ISR Center is the Army’s applied research and advanced technology development center for C5ISR capabilities. As the Army’s primary integrator of C5ISR technologies and systems, the center develops and matures capabilities that support all six Army modernization priorities, enabling information dominance and tactical overmatch for the joint warfighter.

By Dan Lafontaine, DEVCOM C5ISR Center Public Affairs

The C5ISR Center is an element of the U.S. Army Combat Capabilities Development Command (DEVCOM). Through collaboration across the command’s core technical competencies, DEVCOM leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more lethal to win our nation’s wars and come home safely. DEVCOM is a major subordinate command of the U.S. Army Futures Command.

——————-

Guest Post sponsored by EXO Charge, and published with permission from the U.S. Army. EXO Charge will be exhibiting the STUB series at the AUSA Annual Exposition on their booth, #860 in Hall ABC. www.exocharge.com