Available tomorrow (5/24/22) at 1100 Eastern time, the Tactical Distributors exclusive? Altama OTB Maritime Assault Mid in Desert TigerStripe!

www.tacticaldistributors.com/products/altama-x-td-otb-maritime-assault-mid-desert-tiger-stripe

Available tomorrow (5/24/22) at 1100 Eastern time, the Tactical Distributors exclusive? Altama OTB Maritime Assault Mid in Desert TigerStripe!

www.tacticaldistributors.com/products/altama-x-td-otb-maritime-assault-mid-desert-tiger-stripe

Watertown WI, May 20th, 2022– The Griffin Taper Mount system has been satisfying customers for over a decade with it’s simplistic, robust, and affordable mounting system. A QD system however, offering an active retention system is often times demanded by government customers. A quality QD system should be accurate, robust, reliable, require minimal training, and be free of wear prone metal on metal teeth or ratchets, thereby guaranteeing a longer trouble free service life with minimal maintenance needed. Griffin’s DUAL-LOK™ QD mounting system was designed around these objectives.

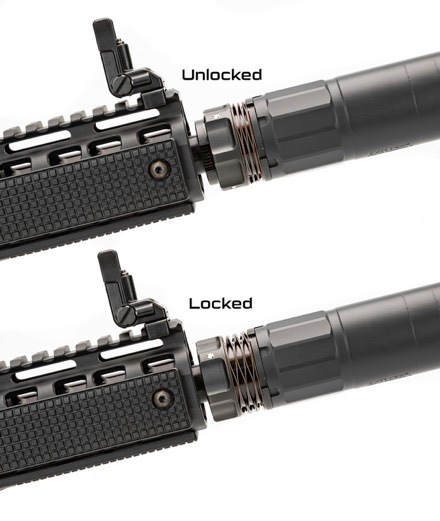

What makes this mounting system unique? It is a combination of desirable mechanical features and performance characteristics in a lightweight, yet compact system. DUAL-LOK™ has great potential for widespread product application. A precision taper interface (one locking feature) between the mount and the device ensures accuracy. An ACME thread, provides speed and ease of attachment. A robust 17-7 Wave spring (718 Inconel on DUAL-LOK™ suppressors) provides a reliable and positive heat resistant spring action to the redundant locking collar (second locking feature). The locking collar is semi permanently installed to the mount via factory pressed splined taper pins. Since the mount has no wear prone metal on metal sliding actions like many other mounts, there is no need for the operator to disassemble the system. This locking ring includes three anti-rotation teeth which ensure the suppressor will not come off inadvertently. The muzzle device integrates 60 machined anti-rotation splines which is doubled by the mount’s two locking positions, hence the double entendre DUAL-LOK™. How is this achieved? The mounts’ two locking positions are machined out of phase of one another by 3 degrees which provides the system with 120 different locations to lock and ensures that when the suppressor is firmly screwed onto the taper a locking spline will be at an ideal location to ensure a rigid and locked suppressor. When the suppressor is firmly attached, only one of the two lock positions will work allowing the spring to push the locking collar rearward over the splines. Every time the operator attaches the suppressor they will articulate the collar to this same locking position.

Substantial efforts are taken in the manufacturing and inspection of the DUAL-LOK™ products to ensure Griffin customers are outfitted with some of the best QD mounting systems in the world.

“I have been studying and designing silencers most of my life, and I am very proud our team for it’s diligence to provide a world class QD mounting system to the market second to none. I spent years, many sleepless nights, dreaming up a system that would check all the boxes and be truly great. We were able to do that. It was a very fun project for me and I am excited to be integrating the DUAL-LOK™ system in several interesting suppressors over the next few years. I have confidence that demanding customers will be well satisfied by this invention.”

– Austin Green, Founder and Engineer

The DUAL-LOK™ system is machined in Griffin’s Watertown Wisconsin facility by freedom loving Americans.

Key points :

• Utility patent pending

• Wear free mounting system, requires no consumable parts

• Taper lock interface ensures security and accuracy

• ACME thread provides speed of attachment

• Locking ring incorporates 3 anti-rotation teeth to eliminate inadvertent loosening

• 120 effective positions ensure a rock-solid suppressor mount and provide extremely low POI shift

• 17-4 stainless steel

• Robust wave spring

• ¾” wrench flats on muzzle devices

• Nitrided black for increased surface hardness, corrosion, and wear resistance

Products Supported :

• 1.375×24 (HUB) DUAL-LOK™ stand-alone mounting system

• DUAL-LOK™ Minimalist muzzle brake

• DUAL-LOK™ Minimalist flash hider

• DUAL-LOK™ 2.25” Stealth Flash Hider

• DUAL-LOK™ Tactical Compensator

• DUAL-LOK™ Titanium Minimalist Brake (6AL4V)

• Suppressors with Integrated DUAL-LOK™ mounts coming soon.

Thread pitches supported:

• 1/2×28 (.22cal & 9mm)

• 5/8×24 (.30cal & .45cal)

• 14x1mm LH (.30cal)

• 18x1mm (.30cal & .338cal)

• 3/4×24 (.30cal & .338cal)

To find out more on Griffin Armament’s entire product line, please visit their website at www.GriffinArmament.com.

The United States Special Operations Command has published an intent to award a sole source IDIQ contract for Personal Defense Weapons to SIG SAUER.

The goal of the program is to provide Operators with maximum firepower in a concealable weapon and they have selected the Rattler, a compact version of SIG’s MCX after having conducted ongoing research and review of viable solutions since 2017.

According to the notice of intent, the IDIQ will provide complete PDW weapons (5.56mm and .300 Blackout caliber) that include suppressors (SIG SL series), cleaning kits, magazines, quick barrel change kits and force on force training kits. Furthermore, parts, sustainment, and New Equipment Training will also be part of this IDIQ.

In 2018 USSOCOM awarded SIG SAUER a contract for the Suppressed Upper Receiver Group program which is also based on the MCX. While the PDW contract will deliver complete weapons, SURG is a SOF unique specialized upper receiver which is attached to the M4A1 lower receiver.

After refinement of the design in conjunction with USSOCOM, SIG began delivering SURG last fall. In these images of SURG the version that won the contract includes a mesh cage around the suppressor but was delivered in the low-profile variant shown detached from the M4A1.

SIG CEO Ron Cohen recently shared in an interview the work they have accomplished to reduce the amount of toxic fumes shooters are exposed to while firing suppressed weapons. He explained that the M4 unsuppressed is 100 parts per million at the shooter while the Mk 18 exposes the shooter to four times the amount of an unsuppressed M4. SURG exposes the shooter to less than an unsuppressed M4.

There will be a short comment period for the Notice of Intent to award the sole source contract for PDWs. After that, the contract will be awarded.

The RDS (Red Dot Sight) Handgun for Law Enforcement program from Victory First was the first RDS course to be approved and selected by the Maryland Police and Correctional Training Commissions to be taught at their firearms training facility.

The Owner of Victory First, Matt Jacques is a retired Law Enforcement Officer from Virginia. Since his retirement, he has had over 15 years of RDS experience in firearms development and instruction specifically focused on the specialty of RDS handguns and Law Enforcement. As the Senior Manager of Assault Weapons employed by FN America, he was part of the development team for the Joint Combat Pistol (JCP) program which was eventually offered on the commercial market as the FNP45 Tactical. That was the first handgun with RDS mounting capabilities to be offered on the market from a manufacturer. He has conducted RDS transition programs for several Federal and major Law Enforcement agency teams and Firearms Training Units in the last decade since starting Victory First.

In 2019, Matt was contracted by VirTra, the advanced Law Enforcement firearms simulator company to develop and assist in launching the first simulator based RDS Transition program. Launched at Shot Show 2022, that program was the first of its kind and now allows VirTra customers to train in the simulators on RDS based training and sustainment programs.

“It is an honor to have been chosen to help get the Officers from the state of Maryland RDS implement their handgun training.” said Matt Jacques of Victory First. “This program was developed to help them make educated decisions on how to choose the gear that meets their requirements, but how to write the requirement, then conduct proper testing and procurement of that gear, then how to employ it correctly to keep themselves safe and protect their citizens with better equipment. The speed at which the RDS Handgun has been growing in acceptance within the Law Enforcement community is moving faster than anything I have witnessed in nearly 30 years of being a cop or involved with the training of this profession.”

Jamie Green, Rangemaster for the Department of Public Safety and Correctional Services Maryland Police and Correctional Training Commissions contacted Victory First about their program. “I was hearing from police agencies throughout the state and felt like there was quite a bit of interest in red dot sights for duty weapons. That being said, I also knew there would be a need for both regulation and different training protocols for their use. That’s when a work group was formed to research the sights and recommend changes to the existing Code of Maryland Regulations.”

The first class will be in July at the Maryland State Training Facility in Sykesville, Maryland and agencies can register for any of the classes on the Victory First website www.Victory-First.com.

If your department or agency would like to learn more about the RDS programs or other LE specific courses offered by Victory First, please contact Matt Jacques directly via email: Matt@Victory-First.com

FORT LEONARD WOOD, Mo. — Leaders from U.S. Army Futures Command and the Maneuver Support Center of Excellence wrapped up the two-week Maneuver Support, Sustainment and Protection Integration Experiments — or MSSPIX — this week, giving Army leaders and capability developers a chance to gain insights into the viability of emerging technologies through credible and validated operational assessments.

According to Kyle Henry — the chief of the center’s maneuver support battle lab experimentation branch and one of the key organizers of the event — the annual MSSPIX is an important venue for conceptual and materiel development because of the feedback provided by the very Soldiers who may one day use the technology to assist in accomplishing missions.

“Without the Soldiers, this would be a glorified tech demo,” he added. “That’s not what we’re trying to do. We want a non-biased look at these technologies, these capabilities.”

Henry said the overarching focus of this year’s MSSPIX was to enable protection and sustainment solutions in support of what’s called multi-domain operations — the Army’s attempt to address competition and potential conflict between the United States and countries with relatively similar warfighting capabilities across air, land, sea, space and cyberspace. This includes the mitigation of hazards, the preservation of assets and the protection of Soldiers.

“The technologies being assessed are designed to minimize a Soldier’s presence on the battlefield, or otherwise aid in protecting lives, while also improving the ability to defeat enemy forces, disrupt enemy capabilities and physically control spaces,” Henry said.

During a demonstration day event on May 17, Sgt. Daniel Alexander, with Fort Leonard Wood’s 595th Sapper Company, and Spc. Wyanet Nakai, from the 212th Military Police Company at Fort Bliss, Texas, operated what’s being called the Mobile-Acquisition, Cue and Effector, or M-ACE — one of 14 capabilities assessed this year by a group of more than 20 Soldiers from installations across the country.

Integrating radar technologies with a remote cue system, M-ACE can lock onto and disable a moving target, such as a drone.

Having a system like this in a combat environment is ideal for military police, Nakai said, as they are typically considered what’s called “mounted,” meaning they stay inside their tactical vehicles.

“What we’re doing is controlling the weapon from inside,” she said. “This set up is really nice, and it’s safer.”

For a combat engineer, like Alexander, whose missions require both mounted and unmounted capabilities, it’s nice to know the Army is trying to minimize Soldier risk on the battlefield.

“It’s nice to know we’re going another route for combat [military occupational specialties],” he said. “We go outside the wire, put our lives on the line, and with technology like this, it takes the Soldier out of many of those situations — it minimizes the dangers.”

This was the first time either Alexander or Nakai have participated in MSSPIX. Alexander, originally from Bolingbrook, Illinois, said he was happy for the opportunity to provide inputs that may one day help improve the Army’s ability to more effectively and safely meet its mission requirements.

“I hope other Soldiers in my unit get this opportunity,” he said.

Nakai, from the Navajo Nation in Utah, said it’s fascinating to be part of a project decades in the making.

“I didn’t know what MSSPIX was,” she said. “I’m amazed by how much time goes into these technologies — someone said 18 years for this one. It blows my mind how much thought and effort goes into building a system like this, and they want to keep improving it.”

By Fort Leonard Wood Public Affairs Office

HOUSTON, May 12, 2022 – Check out Comp-Tac®’s website to see a recent video interview with multi-time national and world champion, Rob Leatham, answering questions about what he looks for in a holster.

Leatham recently visited the Comp-Tac factory in Houston, Texas, where he learned more about the Comp-Tac manufacturing process, variety of products and met with staff pertaining future Comp-Tac projects. While in house, Leatham and Comp-Tac general manager Gordon Carrell were able to sit down and talk about holsters and what Leatham looks for and has learned over the years.

Interview includes questions covering: Rob Leatham, Brand Ambassador visits Comp-Tac – YouTube

– Leatham’s reaction to learning about the Comp-Tac’s manufacturing process.

– What does Rob Leatham look for in a holster?

– How Leatham tested the Comp-Tac products before he became a brand ambassador.

“Getting to work with Rob has been an amazing opportunity so far. In just a few short months we have already come together on ideas for expanded, new and potential projects. Having Rob in Houston to see what we do and meet all the Houston staff was an excellent step for the continued growth of Comp-Tac’s brand and we are excited to keep sharing information with each-other and our customers,” explained Gordon Carrell general manager of Comp-Tac.

Most people wear something under their wetsuit to help with getting their wetsuit on and off easier. The other reason for wearing something under your wetsuits is that the extra layers can help keep your body warmer. Instead of wearing a thicker wetsuit that will restrict your movement, it allows you to wear a thinner suit that will give you more flexibility. You can wear a short sleeve top or bottom to help keep your core warmer. The other thing to think about is the air temperature/ wind on your way to the dive site. Suppose you are worried about the air temp/ wind when you are traveling to the dive site. In that case, you can wear heavyweight GoreTex or a linebacker jacket (the kind made for helo’s flights/ football players wear on the sidelines) is excellent to have as you can take it off before the dive and put it on when you are done.

SCUBAPRO 1.5mm Everflex SS top

For colder temperatures, adding layers underneath the suit is the way to go. You have several options to choose from. If you already have a thinner wetsuit that you usually use for warmer environments, a 1mm rash guard, or any other type of garment that’ll provide you with the added warmth around your chest will help. SCUBAPRO makes a great 1.5mm top and bottoms in short and long sleeves, shorts, and long pants. This 1.5mm is very warm, and to me, it feels like I am wearing a 2-3mm.

SCUBAPRO 1.5mm Everflex long pants

When you have to worry about the wind, most surf wetsuits or wetsuits glossy like surf suits are made to stop the wind. That all-suit surf suits are not great for diving as most are not made from a material (yes, surfing is different than diving) that is designed to be used underwater for long periods. Some people like to wear nothing between them and their wetsuits. This can be painful after wearing a wetsuit for a long time, especially on a long wet Zodiac ride. Due to the constant rubbing against their skin, it begins to chafe ( AKA Baboon a$$). Usually, the neck, armpits, behind the knees, and the crotch are the first to go. You can apply anti-chafing gel/ Vaseline to help with this on long dives and rides. There is also stuff like Butt Paste, Triple paste, or Anti monkey butt paste.

SCUBAPRO 1.5mm Everflex LS top

You can also wear dive skin or bike shorts; this will help with donning and doffing your suit on and off also. I have started to use compression shorts. (They make tops also) They are made with a material called Celliant; it is a mineral-infused fabric to take the energy you give off when you work and reflect it into your muscles, increasing blood flow and helping them work harder. As your body emits energy, the mineral-infused fabric absorbs & reflects it, improving endurance. (I know this sounds crazy, but I am a big believer in Celliant)

Whatever you decide to wear, keep in mind the water/ air temperature, duration of the dive, and what you will be doing. Also, one reason you should make sure to keep a logbook of all your dives. That way, you can look up what you have used in the past for this situation. That should put you at a good starting point. Now that you’re aware of your options, it’s time to get to specifics. What type of undergarment is right for your needs, or do you even need to wear anything under your wetsuit at all?

SCUBAPRO 1.5mm Everflex

Well, that depends on you. In warmer waters, you can get away with wearing undergarments with minimal coverage (swimsuits, trunks, and other similar items)—or even nothing at all. Many people prefer to go commando under their wetsuits, but it’s all a matter of preference. If you plan to rent the suit, however, you’re probably going to want to wear something underneath.

SCUBAPRO 1mm Topical wetsuit

For colder temperatures, adding layers underneath the suit is the way to go. You have several options to choose from. Suppose you already have a thinner wetsuit that you usually use for warmer environments. In that case, you can opt to add a jumpsuit, rash guard, or any other type of garment that’ll provide you with the added insulation you need. This way, you won’t have to purchase another suit.

SCUBAPRO Hybrid Hood Vest

Or, if you’d instead go naked warrior underneath, you can get a thicker wetsuit. Deciding what to wear ultimately depends on the environment (and temperature) you plan to dive in, how sensitive your body is too cold, and many other variables. Make sure to consider all factors before you buy anything, and always try it in training before you use it for the first time when it matters the most.

Rheinmetall has received several major orders from a NATO customer to supply components for force protection equipment. The orders are worth a total of nearly €250 million gross. Delivery of the components is expected to start in 2023 and be complete by 2025.

“The armed forces of our country and those of our partner nations rely on our products to protect those who defend our right to live in peace, freedom, and security,” said Armin Papperger, CEO of Rheinmetall. “We have made it our mission to provide our men and women in uniform with the best possible equipment, giving them a vital edge when deployed in harm’s way and helping to ensure that they get home safely. Aware of what is at stake, our staff give their best every day.”

Rheinmetall’s comprehensive expertise in force protection technologies ranges from individual passive ballistic solutions such as hard ballistic inserts for protective vests to state-of-the-art stand-off active protection systems for armoured fighting vehicles.