NATICK, Mass. — Proper nourishment is key to achieving great heights. This is especially true for the elite group of pilots who rely on the expertise of the Combat Feeding Division, part of the Soldier Sustainment Directorate, at the U.S. Army Combat Capabilities Development Command Soldier Center, or DEVCOM SC.

The Combat Feeding Division’s food technologists, equipment specialists, engineers, microbiologists and packaging specialists have been perfecting tube foods for almost 60 years. DEVCOM SC is the only place that designs and produces the foods that meet the specific needs of the Air Force’s U-2 reconnaissance aircraft pilots and the National Aeronautics and Space Administration’s, or NASA’s, ER-2 research aircraft pilots.

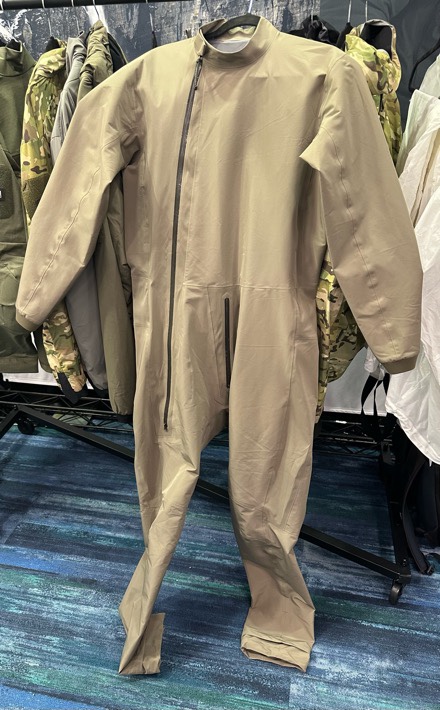

Elite pilots wear pressurized suits and helmets to perform their missions. The foods, which have a pudding-like consistency, come out of a container about the size of a large tube of toothpaste.

The tube foods are attached to feeding probes that are inserted into an opening in the helmets.

The tube foods help pilots power through missions that can last up to 12 hours. The foods come in 19 different offerings, including entrees, fruits and desserts. Choices range from chicken with tortilla soup, to hash browns with bacon, to key lime pie, to chocolate pudding with caffeine — to name just a few. Given the difficulty and length of pilot missions, caffeine is included in some of the selections. The offerings keep evolving. CFD plans to add pasta with marinara sauce next year as well as a new vegan option.

DEVCOM SC’s longtime and unique innovation and expertise in food science and technology and food packaging play a substantial role in tube food development.

“The Combat Feeding Division has a long history of developing nutritionally optimized, good-tasting ration products to meet warfighters’ unique needs and preferences,” said Erin Stomberg, PhD, RD, division chief of Combat Feeding. “The tube foods produced by the division food technologists are one important example of this. Air Force pilots on long flight missions need nutrition for sustainment and performance of their mission, and we are honored to provide this service to them. We accomplish this by using our knowledge of food product development and food processing technologies available in our pilot plant and listening to customer feedback in order to formulate custom varieties based on pilot preferences.”

Daniel Nattress, a food technologist who has served as the project officer for the Tube Food Program for 24 years, pointed out that “decades of knowledge and expertise go into every tube.”

“We have the expertise to make healthy, wholesome foods that taste good, meet nutritional requirements and meet required shelf-life requirements (three years at 80 degress Fahrenheit and six months at 100 degrees Fahrenheit),” said Nattress. “We also need to know how to manufacture foods which meet the nutritional requirements and still fit through the narrow straw-like probe.”

Nattress explained that colleagues in the Tube Food Program also have the “knowledge and expertise to operate the specialized equipment, as well as pack the tube food for safe storage and transportation.”

Equipment upgrades have improved the process. A new state-of-the art tube filler and sealer is easier to clean and maintain than the previous version and a new steam retort, which preserves the tube foods, is more efficient and extremely reliable.

Direct interaction with pilots is key to making the best product. Nattress and his colleagues have visited the home base of the U-2 pilots several times, and the pilots have visited Combat Feeding as well.

“Face-to-face contact is essential to understand what products the pilots want and for them to understand our capabilities,” said Nattress. “We conduct surveys with the pilots every three or four years to verify what they currently like, what they’d like to have and any changes they’d like to have. When we were at Beale Air Force Base, the training base, we got to try on the U-2 suits. This gave us an understanding of what they go through on their missions.”

DEVCOM SC’s efforts to understand pilot needs and to provide them with a quality product are reflected in comments from the U-2 pilots themselves:

“Caff apple pie (Caffeinated Apple Pie) is a must after 8 to 10 hours and preparing to recover the hardest jet in the world to land!”

“Nothing better than hash browns and bacon (Hash Browns with Bacon) after you kick on the autopilot during climbout to an early morning sortie.”

“Not only does it give us some energy, but it’s something we look forward to — especially truffle mac (Truffle Macaroni and Cheese). Delish.”

Comprehensive review sessions also provide Combat Feeding with additional insights.

“We also participate in the twice-yearly U-2 Program Management Reviews, a meeting of all government agencies and contractors,” said Nattress. “These meetings give us an overview of the entire U-2 program from Tube Foods to U-2 suits to the airframe. This gives us the overall picture and shows us where we fit in.”

Robert Bernazzani, team leader of the Joint Foodservice and Engineering Team, praised the comradery of the experts who produce the food tubes, their eclectic set of skills, and their creation of a quality finished product.

“It is very gratifying to be part of such an important and vital program for the military,” said Bernazzani. “Most of the work that is done in Combat Feeding is research and development. This program is unique because we actually not only do the R&D but produce the tubes that are consumed by the warfighter.”

“Everyone who works on the Tube Food Program, that includes several others from packaging specialists to microbiologists, are very proud to provide U-2 pilots the sustenance they need to perform these vital reconnaissance missions,” said Nattress. “When we have had the opportunity to visit Beale, or to host pilots, they are very appreciative of the products we are able to manufacture.”

By Jane Benson, DEVCOM Soldier Center Public Affairs