WASHINGTON — To give Soldiers what they need to win the nation’s wars now and in the future, the Army must continuously transform and adapt to advances in technology, said Gen. James E. Rainey, commanding general of Army Futures Command.

This flexibility is needed, he said, because of how quickly the environment is evolving.

“The amount of technical disruption in the character of war is unprecedented, and it just continues to go faster and faster,” he said during a keynote presentation at the U.S. Army Global Force Symposium in Huntsville, Alabama last week. “Whatever you think you know this year, come back in 90 days, and you’ll know something different.”

To combat this changing landscape, the service is focused on transformation in three different periods: 18-24 months, two to seven years, and seven to 15 years. Work done in each period has a ripple effect on the others.

The first period is referred to as transformation in contact. This area deals with capabilities delivered to deployed warfighters for testing and analysis. They provide real-world feedback allowing the Army to make necessary adjustments for future use.

In this area, the Army can adapt to current warfighting conditions. This was used when the service noticed the value of loitering munitions, also known as suicide drones, in the war in Ukraine. Army Futures Command put in a priority-directed requirement and is in the process of buying the capability.

AFC is also working with industry partners on ground-based rockets, ground-based missiles and counter-unmanned aircraft systems that work on offense to protect light infantry and armored companies.

“The United States Army, we believe in offense and attacking,” he said. “So, there is a big opportunity to figure out how we are going to provide effective counter-UAS capabilities to units on offense.”

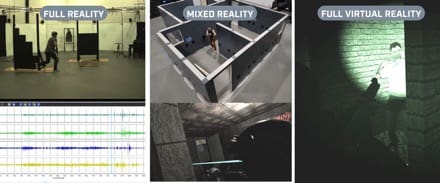

Human-machine integrated formations is another initiative the service is working on in the 18–24-month period. This program brings robotics and autonomous vehicles into fighting formations. The goal of the project is to keep Soldiers out of harm’s way whenever possible.

The Army tested numerous integrated formations during Project Convergence Capstone 4 in Fort Irwin, California last month.

“This is one of our major efforts inside the Army,” Rainey said. “It’s going very well and is full of opportunities to go to the next level. We’re never going to replace humans with machines, it’s about optimizing them.”

The Army will start prototyping the first integrated platoons in the next two years.

The two-to-seven-year period is known as deliberate transformation. In this time frame, the service is continuing to work on the Future Long Range Assault Aircraft, extending the range of cannon artillery, adding magazine depth and improving indirect fire weapons, engineering capabilities and the network.

Rainey said the service’s number one priority in deliberate transformation is improving the network. The service is working on a data-centric system to enable commanders to make quicker and more informed decisions.

The Future Long Range Assault Aircraft is a hot topic issue with the service’s recent aviation rebalance. Rainey assured that the Army is committed to FLRAA and the capability it brings to maneuver rifle squads.

“We don’t do attrition warfare,” he said. “We do maneuver warfare. So, FLRAA is an absolute must we have to continue to deliver, and it’s in good shape.”

Innovating in engineering battalions is another key priority for the Army, he explained.

“We’re more likely to get stopped by the terrain than by an enemy we fight and that’s not OK,” he said. “We [have got to] get after the engineering transformation and modernization.”

The Army announced the end of the Extended Range Cannon Artillery platform program last month but the requirement to extend cannon fire remains. The service recently completed a tactical fires study on artillery modernization. The research from the study showed significant success in extending the range by making adjustments to the rounds, Rainey said.

AFC is taking this knowledge and looking at ways to innovate the rounds and the propulsion systems. They are also looking to increase magazine depth to give Soldiers not just the capability but the capacity they need.

The last time frame is referred to as concept-driven transformation. This is where the Army is looking to sustain advantages, develop new capabilities and build endurance for future conflicts.

The service is working on merging offensive and defensive fire systems, adding robotics to contested logistics, bringing survivability and lethality to light infantry divisions, decreasing the weight of armored formations, and increasing its emphasis on war gaming.

This continuous transformation over all three periods is meant to make the Army more adaptable, flexible and lethal while giving Soldiers the capacity and capabilities to win now and in the future.

“Whatever we do as we transform, we have to preserve that people advantage we have,” Rainey said. “They are our greatest asset.”

By Christopher Hurd, Army News Service