A recently issued report from the Department Of Defense’s Director, Operational Test and Evaluation Office (DOT&E), on the Modular Handgun System has been picked up by bloggers and the headlines have been sensational. They’re being shared online at face value, with few people taking time to read the source document. You can read the whole thing here, and I encourage you to do so, but I’ll use extracts throughout this article.

I’ve spent the past few days going back and forth with DOT&E and PEO Soldier, who manages the program, to clarify information in the report.

From the received responses, apparently the situation is not as dire as the authors of other stories would like their audience to believe.

Background

Each year, the Department Of Defense Operational Test and Evaluation Office (DOT&E) submits an annual report of test and evaluation activities to Congress.

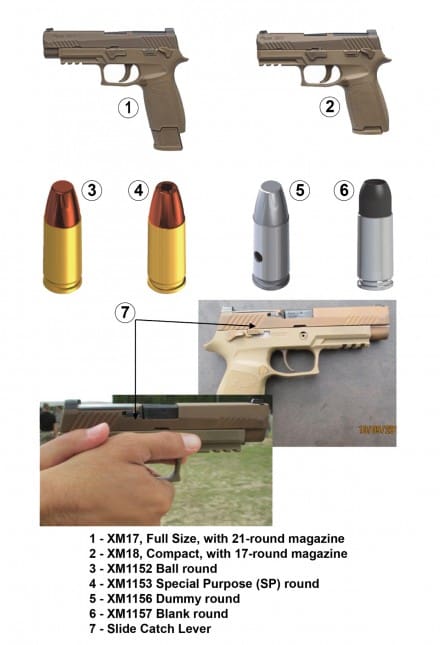

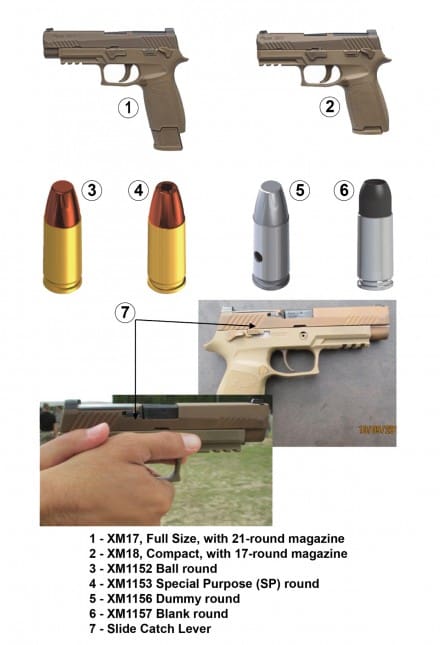

The 2017 report was published on 26 January, 2018 and includes details on numerous test activities in support of Army procurement, including those of the joint Modular Handgun System. MHS consists of militarized versions of a standard (M17) and compact (M18) pistol, manufactured by SIG SAUER and based on their commercial P320 9mm model. the weapon has a common trigger pack and swappable frames to make the switch from M17 to M18.

The weapon was selected for procurement just a year ago on January 19, 2017. Since then, it has served as a model for fast track acquisition reform.

The procurement announcement was met with displeasure from fans of fellow contender GLOCK who pointed to G19 use by USSOCOM as ample reason to broaden its issues within DoD. The SIG contract award was formally protested by GLOCK, but their effort was not sustained by the Government Accountability Office.

Drop Misfires Background

In August of last year, a blogger demonstrated that the commercially available SIG P320, which the MHS is derived from, would unintentionally discharge if dropped at a certain angle. Almost immediately, the internet began to call into question the safety of the Army’s version of the handgun. SIG analyzed the problem and quickly issued an interesting fix for their commercial gun; a new trigger pack based on the MHS trigger. SIG stated that the Army’s handgun already had a different, lighter trigger than the civilian model and had not demonstrated the same issue. SIG offered a voluntary upgrade to the new trigger for P320 users.

In November, I attended a media round table hosted by PEO Soldier to provide an update on fielding of MHS. One of the topics was unintentional misfires caused by dropping. LTC Steven Power, Product Manager Individual Weapons, Project Manager Soldier Weapons, assured everyone that MHS has not experienced such a failure.

Naturally, when I ran across this statement in the DOT&E report, I wanted clarification, because it went against everything I’d been told.

“During drop testing in which an empty primed cartridge was inserted, the striker struck the primer causing a discharge. SIG SAUER implemented an Engineering Change Proposal (ECP) to correct this deficiency by implementing lightweight components in the trigger group mechanism. This fix may have contributed to the splintering of two triggers during the IOT&E”

DOT&E Report

DoD Drop Testing

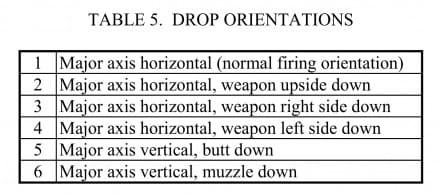

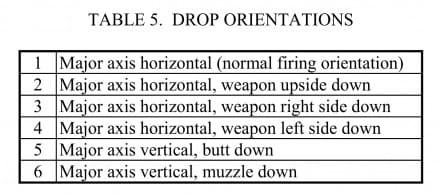

Before I get into what I learned about this statement I need to explain how DoD conducts drop testing. The procedure is contained in 4-10 of Test Operations Procedure 03-2-504A “Safety Evaluation of Small Arms and Medium Caliber Weapons” . The actual test is called the 1.5 m (5 foot) drop test which requires that a firearm loaded with a primed, empty, cartridge case be dropped from the height of 1.5 m unto a clean, dry, and level concrete surface at six different angles. The goal is to see if the firearm discharges or if the drop affects the function of the weapon.

SIG SAUER’s Position

Since I had discussed the drop misfire issue with SIG in the past, I thought I should check with them. They responded by telling me that it was DoD’s report and they’d be the best place to seek out my answers.

Requesting Clarification From DOT&E

Initially, I contacted DOT&E with a list of technical questions. In particular, I wanted to know when and how they identified this malfunction. After some deliberation, DOT&E spokesperson, LTC Michelle L Baldanza offered this statement regarding the technical questions I had posed, “I will have to let the report stand for itself. You are welcome to contact the Army about this.”

What she was telling me was that the information had originated with the Army and all they had done, was collate it into their report. I’d need to go to PEO Soldier for the answers I was seeking.

PEO Soldier Responds

I approached PEO Soldier about this statement, asking how and when it had occurred. They did not provide details on any test failures but rather provided the statement below, which seems to refute the DOT&E report.

When tested in accordance with the TOP 03-2-504A, the weapon passed in all drop orientations.

PEO Soldier

Even then, despite several requests, they refused to provide a date when the 1.5 m TOP drop test protocol was accomplished. It should have initially been accomplished during source selection, while the Army evaluated the vendors’ candidate pistols and I was able to verify this information from other Army sources who were not authorized to speak publicly about the topic.

Splintered Triggers

The DOT&E report mentioned two “splintered” triggers. Of course, this became a central theme to call the program into question. I asked about the issue. The triggers still worked. PEO Soldier related that they “did not remain smooth and comfortable to fire,” saying it was an isolated issue, and not the result of a design flaw or on-going manufacturing problem. To put it into perspective, they’ve only encountered this issue in two pistols, out of approximately 10,000 purchased to date. It’s so rare, it shouldn’t have found its way into a report intended to discuss major issues.

Ammunition / Reliability Issues

MHS includes four 9mm cartridges, manufactured by Winchester, but there are two primary rounds. The XM1153 Jacketed Hollow Point (referenced above) also referred to as a “special purpose”‘and the XM1152 Ball.

Additionally, there are two reliability factors, Mean Rounds Between Failure and Mean Rounds Between Stoppage. Both MRBF and MRBS were measured during Product Verification Testing as well as Initial Operational Test & Evaluation.

MHS was tested for MRBF and MRBS in both M17 and M18 configurations with JHP as well as Ball ammunition.

According to the DOT&E report, the MRBF reliability requirement for MHS is 5,000 MRBF for a 98 percent probability of completing a 96-hour mission without a failure. The MRBS reliability requirement is 2,000 MRBS for a 95 percent probability of completing a 96-hour mission without a stoppage.

During PVT which is an early test, the XM17 and XM18, with special purpose munition, met its requirement for both MRBF and MRBS:

– The XM17 demonstrated 8,929 MRBF (99 percent probability)

– The XM18 demonstrated 8,333 MRBF (99 percent probability)

– The XM17 demonstrated 1,923 MRBS (95 percent probability)

– The XM18 demonstrated 2,155 MRBS (96 percent probability)

During PVT, the XM17 with ball ammunition met its requirement for MRBF but not its requirement for MRBS. The XM18 with ball ammunition did not meet its MRBF or MRBS requirement.

– The XM17 demonstrated 6,944 MRBF (99 percent probability)

– The XM18 demonstrated 3,906 MRBF (98 percent probability)

– The XM17 demonstrated 343 MRBS (75 percent probability)

– The XM18 demonstrated 197 MRBS (61 percent probability)

Obviously, there’s a difference in how reliable the weapon is, based on the ammo used, and pistol configuration. Consequently, the Army decided to investigate the Ball ammo issues and moved to the next phase of testing solely with the JHP cartridge, which they consider is their “go-to-war” ammunition.

During IOT&E, 60 of 120 stoppages for the XM17 and 63 of 85 stoppages for the XM18 were failure of the slide lock to the rear at the last round. At least some of these stoppages were the result of poor grip. Additionally, 60% of these stoppages (75 of 123) were experienced by just eight shooters out of the 132 who participated in the IOT&E. Based on information from the Army Marksmanship Unit which is cited in the DOT&E report, it appears that the majority of those stoppages were caused by shooters disengaging the slide catch with their thumbs.

Once the Army understood it’s a software and not a hardware problem, they began to modify Marksmanship Training to ensure that Soldiers do not unintentionally engage the slide catch lever when firing the MHS. It’s a simpler solution than redesigning weapon parts.

In fact, the MRBS demonstrated during IOT&E is significantly increased if this stoppage is eliminated:

– The XM17 demonstrated 708 MRBS (87 percent probability).

– The XM18 demonstrated 950 MRBS (90 percent probability).

The weapon is capable of meeting the standard, given the right shooters.

Although they have a Conditional Material Release for both types of ammo and have been firing them since November, PEO reminded me that MHS meets, or exceeds, all operational requirements, including MRBS, with the XM1153 jacketed hollow point ammunition for which it is optimized.

While I take issue with how some things are presented, overall, the Army agrees with the findings in the report.

“The DOT&E report accurately conveys the test results. It is normal and expected during testing to find opportunities to improve a system. The testing determined that the MHS had a lower Mean Rounds Between Stoppage (MRBS) with ball ammunition than it has with the “go-to-war” jacketed hollow point round for which the system is optimized. In July 2017, the Army formed a Tiger Team to perform a detailed root cause analysis of the ball ammunition issues. Their analysis has resulted in a number of modifications expected to enhance MHS performance and reliability with ball ammunition.”

PEO Soldier

Much has been made on other websites about the pistol’s performance with the XM1152 Ball ammunition. Which, by the way, is a new cartridge, unique to this weapon. The truth is, it is safe to operate with both.

However, this isn’t good enough for the Army as they continue to consider performance improvements. PEO Soldier spokeswoman Ms Dawson explained, “It is simply not meeting its reliability requirements with the ball ammunition and has experienced stoppages and issues with “double ejections”. Double ejections? I’m intrigued.

Double Ejections

Aside from the drop testing issue, I had hoped to get to the heart of “double ejections”. It’s referenced early in the DOT&E report.

“Both the XM17 and XM18 pistols experienced double-ejections where an unspent ball round was ejected along with a spent round.”

DOT&E Report

Until this week, I’d never heard the term used. PEO Soldier echoed the DOT&E definition.

“A double ejection is when a live unfired round is ejected along with the casing from the round that was just fired.”

PEO Soldier

Semi-Auto pistol’s don’t work that way, it’s a physical impossibility. So, I asked both DOT&E and PEO Soldier to further describe the malfunction in case it has a more commonly used name. Neither organization would. And yet, they’ve used it; over and over. PEO Soldier even set up a Tiger Team to get to the root cause of it. Reporters have parroted it as it were a common term. I even approached several individuals with extensive experience in Army pistol marksmanship and they were also unfamiliar with the term. Since nobody knows what it is, I’m not sure how they’re going to fix it. But whatever it is, the weapon is performing while using the JHP ammo.

In Summary

What we’ve learned:

-MHS is safe and passes drop standards

-MHS is reliable

-The trigger works

-Stoppages can be mitigated with training

-It introduces a jacketed hollow point ammunition capability

-The Army is working to improve its performance with Ball ammunition

-No one knows what a “double ejection” is except PEO Soldier, and they’re not telling

But this is the most important at part of this whole story. The Army is very confidant in MHS. In fact, PEO Soldier spokeswoman, Ms Debi Dawson released this statement:

Testing was conducted with warfighters from all Services, and their feedback about the MHS has been overwhelmingly positive. The MHS meets, or exceeds, all safety and operational requirements with XM1153 jacketed hollow point ammunition for which it is optimized. The test results published in the Director of Operational Testing and Evaluation (DOT&E) report are being used to make the MHS even better.

PEO Soldier

Unfortunately, there are some pieces of data in the report which seem to be given greater importance than they should be, once put into perspective. In another case, testing which is claimed to have taken place hasn’t been accounted for, and refuted in other statements.

Greater care should be taken when providing input to these annual reports. They are used by Congress to monitor key programs. Additionally, the data has been used to undermine confidence in a program that is doing very well, as new unit after new unit is equipped with this improved capability.

Conclusion

There’s a reason DoD tests. Every program finds unanticipated issues which must be fixed in order to field the piece of equipment across the force. Some come up years after a system enters service. If you read through the entire 2017 DOT&E Annual Report, you’ll find issues of every type, arising for every program showcased in the document. While much has been made online about MHS, when you break it down, it’s not as bad as it’s been made out to be, if you know what questions to ask.

Under the terms of the contact, Gentex will have responsibility for the airworthiness of the Bristow inventory of aircrew helmets, which are exclusively ALPHA 900 Helmets. Support was customized to meet the Bristow SAR specific needs and includes technical services (helmet fitting, records management, and training) and sustainment support (preventative maintenance; repair, and spares inventory management).

Under the terms of the contact, Gentex will have responsibility for the airworthiness of the Bristow inventory of aircrew helmets, which are exclusively ALPHA 900 Helmets. Support was customized to meet the Bristow SAR specific needs and includes technical services (helmet fitting, records management, and training) and sustainment support (preventative maintenance; repair, and spares inventory management).