ABERDEEN PROVING GROUND, Md. – We still own the night.

The PVS 14 night vision monocular and PAS 13 thermal rifle optics are technologies of the past as the Enhanced Night Vision Goggle – Binocular (ENVG-B), Nett Warrior, and Family Weapon Sights – Individual (FWS-I) deliver leap-ahead capabilities to ensure overmatch against near-peer threats in all domains.

Soldiers from the 101st Airborne Division spent three weeks at Aberdeen Proving Ground learning and testing the new equipment set as a part of the program’s guiding Soldier Centered Design philosophy that ensures end user feedback at every step of the technology’s development.

“The ENVG-B is leaps and bounds beyond what we have now, it’s really impressive technology,” said SPC Timmoy Ellis, 2-506, 101st Airborne Division. “My first time in a unit when I tried out the old NODs [night observation device] last year, I got lost and was all the way on the other side of where I was supposed to be. So this will especially help the new guys that haven’t walked in the field at night, they’ll be able to see exactly where they’re going. I wouldn’t have gotten lost if I had these ENVG-B’s, that’s for sure.”

The ENVG-B’s dual tubes feature high-definition white phosphor and overlaid fused thermal technology. ENVG-B Program of Record prototypes are making marked advancements from legacy PVS-14s and previously fielded Enhanced Night Vision devices.

“The white phosphor fused with the thermal overlay helps a lot as well,” said SGT William Williams, 3BCT, 2-506, 101st Airborne. “The good thing about it is the mode that may work best for me, may not work for one of my Soldiers. It has lots of settings to where they can adjust whether they want more white phosphor or more thermals, so in situations where you’re not getting a lot of ambient light you can crank the thermal up and really see anything that picks up heat or puts off a heat signal.”

This ENVG-B capability set features more mode options with the added ability to interface with Nett Warrior’s AR tools in multiple goggle modes.

“When you integrate those technologies you’re going to increase situational awareness and also lethality at night,” said MAJ Bryan Kelso, PEO Soldier Assistant Product Manager for ENVG-B. “You get added capabilities such as rapid target acquisition, the ability to passively bring the weapon optic into the goggle, and also augmented reality when you bring in any of the icons displayed on the Soldier’s Nett Warrior end user device [EUD]. Those all feed straight into the ENVG-B goggles so the Soldiers don’t have to open up their EUD and they can keep moving and seeing those graphical icons.”

Increased SA capabilities

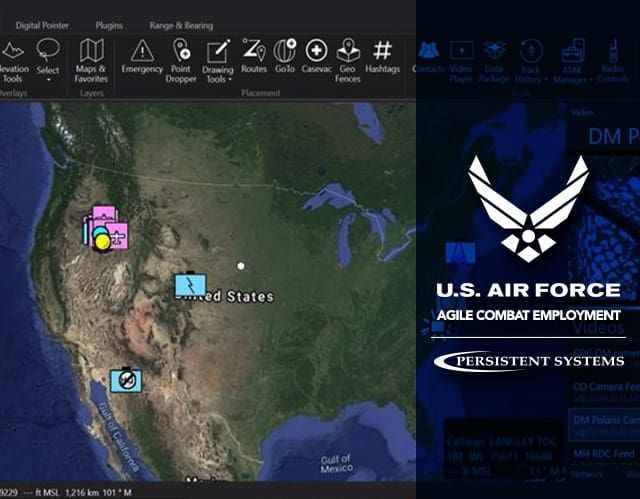

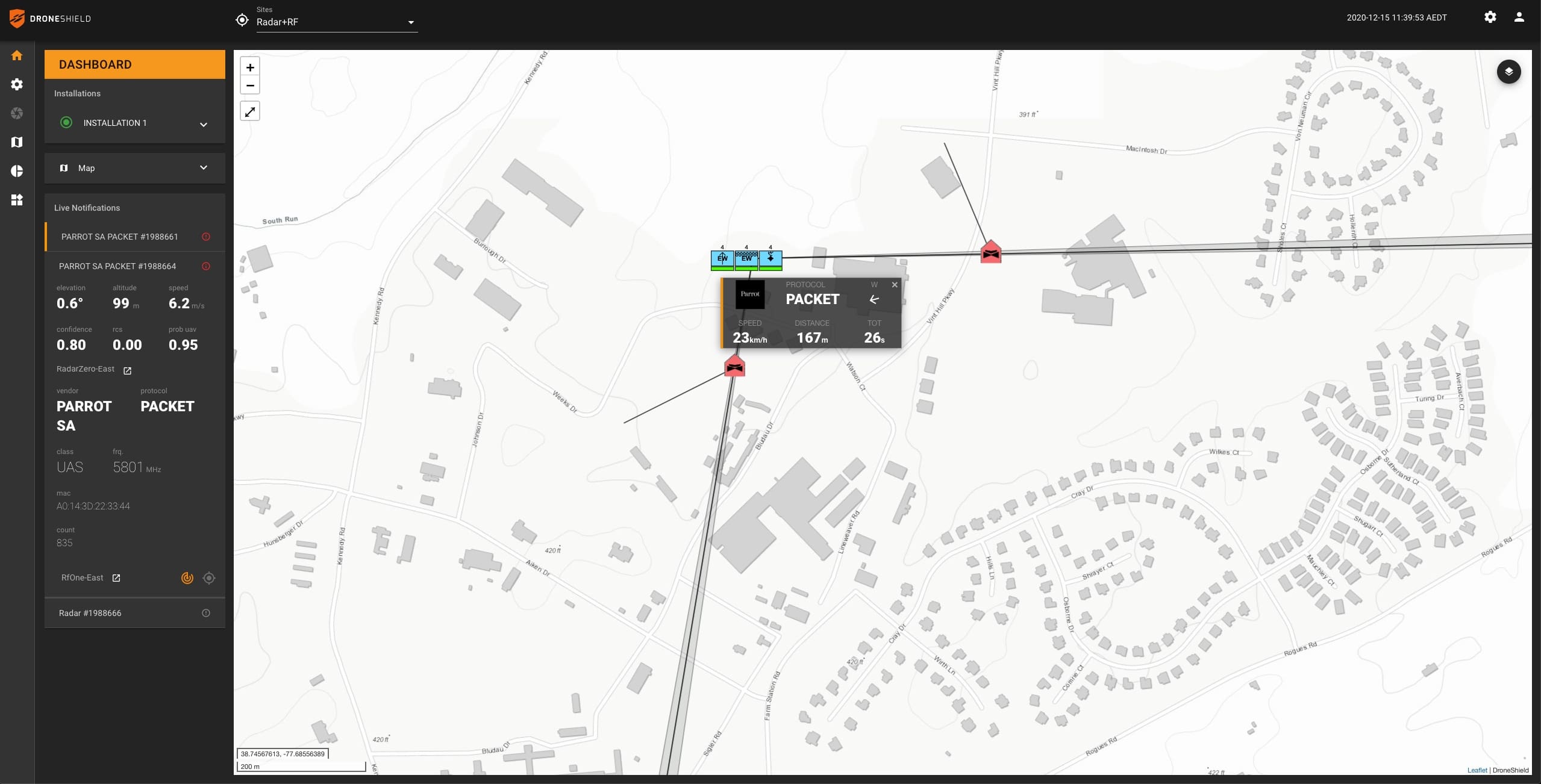

When the high-resolution ENVG-Bs are paired with a Nett Warrior device, the Android Tactical Assault Kit (ATAK) uses AR applications to overlay map graphics and blue force tracking capabilities for increased situational awareness, communication, and mission planning across day and night operations. Soldiers can also enter enemy icons on the EUD and share with others across their network.

“The Nett Warrior technology gives us a better understanding of what we’re getting ready to go do, and helps us battle plan and track each other,” said Williams. “As a squad leader it’s nice to have the Nett Warrior, even if it is not being pumped into the NODs itself I can take that quick tactical pause, flip my phone down on my kit to check it out and see where all my guys are at and see exactly what’s happening on the battlefield.”

“With Nett Warrior you don’t have to be confused,” added Ellis. “You know there’s a river right here so plot to go around it, you know this team is over here, this squad is over there, you know exactly where everyone’s at so you don’t have to stop the formation to look for guys or see if they got stuck at an obstacle, so we can plan accordingly. It’s pretty cool”.

Nett Warrior not only enables increased situational awareness to the dismounted leader, but to higher command and control (C2) as well. The NW system is equipped with a dual channel multi-band radio that enables communication and data sharing on a much larger scale.

“These systems help make communication to leadership easier because sometimes things get hectic out there and I might stumble up, but now even if I can’t talk at the moment I can hit a button and push everything that I have on my Nett Warrior out to my chain of command so they know exactly what I’ve got going on,” added Williams.

Not only does Nett Warrior deliver increased situational awareness and C2 communication, but it enables more efficient mission planning and execution as well.

“Usually it takes hours or days to plan a mission once it comes down,” said Ellis. “Then we sit down and build a sand table and they say ‘Hey, this is what we’re doing,’ so you don’t really get to see that 3D aspect of it. Now once we know we have to hit this village, we can get it planned out pretty quickly, push the mission package out to the other guys, and knock that mission out.”

Mission planning with Nett Warrior is more efficient, but it is also more comprehensive.

“When you mission plan with the Nett Warrior system you can show that we’re hitting this building here and then you can plan out since we’re hitting this building we can put up support by fire here, the weapons go here, and build from the same operating picture that everyone sees. It’s a really nice concept because everyone can see exactly the lay of the land and exactly what you’re doing in advance before even going in,” said Ellis.

Added range, even from cover and concealment

The FWS-I optic feeds the view of the weapon sight into the ENVG-B goggle display, allowing Soldiers to accurately identify and engage targets at increased ranges without physically being face to face and without the need for a laser.

“The FWS-I is mounted in front of the Soldier’s day optic on their M4, which allows you to passively engage targets in a multitude of ranges out to the max effective range of the weapon,” said Kelso. “You can actually detect targets beyond 600 meters, so past where you could effectively engage with an M4.”

The increased range of the optic will allow targets to be identified at farther distances than ever before, and RTA provides the Soldier a passive solution to engage enemies. Picture in Picture and Full Weapon Sight modes allow the Soldier to accurately engage from behind cover and concealment.

“It’s pretty cool to be able to put my head down and engage targets without actually compromising cover,” said Williams. “I could stay completely behind cover, my eyes and head not even looking in the direction of the target, and utilize my FWS-I pumped into the ENVG-B and effectively engage my targets that way.”

Williams adds, “Another good thing about the FWS-I is that it eliminates us having to use a laser, which is a big thing because if we’re engaging with a near-peer because they will be able to tell where we’re at immediately if we’re using lasers.”

Big picture

The ENVG-B, Nett Warrior, and FWS-I all individually deliver capabilities beyond what is standard in today’s battlespace. The ENVG-B delivers dual tube improved Image Intensification (I2) resolution, fused thermal image, and wireless connection with FWS-I and Nett Warrior. The FWS-I provides enhanced target recognition and passive engagement capabilities, even behind cover and concealment. Nett Warrior provides blue force tracking, improved communication, and mission planning tools.

“It reduces the potential of fratricide issues and can help units link up with each other, especially if you want to remain in radio silence,” said Kelso. “There is also consistent visibility of where those blue forces are on the battlefield and with its dynamic refresh rate feature it refreshes more often based on the Soldier’s movement. When identifying either potential or known enemies that information can also get fed through the unit and immediately populate the common operating picture to inform decision makers at a higher level.”

Together the integrated kit delivers the increased situational awareness, communication, and lethality to save lives and ensure undeniable near peer overmatch.

“It has definitely grown on me,” said Williams. “At first I didn’t like it at all. I was like, just give me the NODS and let’s go on, but it has grown on me and in certain situations I think it can help save lives and win the fight.”

Nearly 5,000 ENVG-Bs have been fielded thus far per an Army Directed Requirement. In parallel, the ENVG-B Program of Record has entered Low Rate Production and continues to prepare for its next major test event involving Soldiers in May at Fort Polk, LA. Nett Warrior will be tested with 2nd Cavalry Regiment in April followed by its fielding to 3rd Infantry Brigade Combat Team 25th Infantry Division in July 2021.

By Courtney Bacon