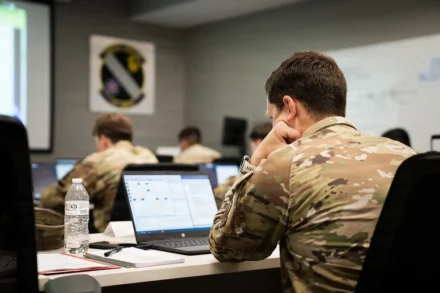

FORT GORDON, Ga.–During Cyber Quest 25, 75th U.S. Army Reserve Innovation Command Soldiers partnered with formerly Army Futures Command’s Futures and Concepts Center Cyber Capabilities Development Integration Directorate’s now renamed, as of Oct. 2, 2025, to the Army Transformation and Training Command’s Future and Concepts Command Cyber CDID, providing a tailored multidisciplinary data team to evaluate multiple emerging technologies, June 3-15, 2025.

As part of its direct support command relationship to T2COM’s FCC, the 75th USARIC’s specialized Army Reserve Citizen-Soldiers routinely provide custom built data teams in support of the Army innovation enterprise – leveraging civilian acquired technical expertise to solve a broad range of data driven warfighting problems.

CQ25 is an annual prototyping and data-centric Army Focused Warfighting Experiment providing capability development and acquisition communities a unique, realistic, and future-focused operationally relevant environment to inform critical capability gaps facing Cyber, Electromagnetic Warfare, Information Advantage and Signal operational forces.

The 75th USARIC helps the FCC drive force design, ensuring that the Army’s future formations are prepared for peer conflict and lead concept development, experimentation, and integration of requirements that translate into real organizations and capabilities.

Force design ensures that new concepts are not just theoretical but that they are turned into capabilities fielded at speed and scale.

CQ25 AFWE drives requirements definition, informs rapid acquisition initiatives, and supports acquisition risk reduction activities.

Leveraging Military & Civilian Expertise for Robust Evaluations while Driving Interoperability Through Collaboration

“The 75th USARIC’s fourteen personnel on-site brought invaluable military and civilian-acquired technical skills in artificial intelligence, data science, and cybersecurity to CQ25, enabling thorough assessments of Cyber, Electromagnetic Warfare and Information Advantage prototypes, expanding their impactful role during last year’s CQ24,” said Lt. Col. Allan Pitchford, lead data analyst for CQ25 and chief, Studies and Analysis, Cyber CDID.

The command’s tailored multi-disciplinary data teams focused on data-driven warfighter problem sets and then finding effective solutions.

During CQ25, “they [75th USARIC Soldiers] assess prototypes to identify capability gaps, test integration with Army systems, and provide actionable feedback for MDO 2028 requirements, collaborating with Soldiers, industry and allies,” Pitchford said. “Their evaluations are vital because their Soldiers, with dual civilian-military expertise, offer unique insights into technology usability and resilience in contested environments.”

There were more than 140 participants in CQ25 testing technology integration to deliver seamless capabilities for brigade and above echelons a key CQ25 objective according to Pitchford, including: Army Cyber Command, the 11th Cyber Battalion, 1st Infantry Division, U.S. Army Forces Command and U.S. coalition partners from Japan, Australia, the United Kingdom, the Netherlands, Singapore and France were also part of the experiment.

CQ25: Testing, Evaluating Innovative/Cutting Edge Technologies for MDO/LSCO

There were 14 vendors on-site with 12 innovative technologies positioned for stress testing and evaluation during CQ25 prior to future continued experimentation and possible acquisition by the Army.

“The 75th Innovation Command brings a uniquely qualified team to support this mission,” said Lt. Col. Shawn Lonergan, officer in charge, Detachment 8, Support Group, 75th USARIC and 75th USARIC CQ25 OIC. “Our Soldiers combine deep operational experience from across the Army—spanning both active duty and reserve components in cyber, signal, and other technical branches—with cutting-edge civilian expertise.”

According to Lonergan, team members work in sectors ranging from energy and financial services to technology and academia, allowing them to approach emerging technologies with a blend of real-world industry insight and military operational understanding.

“This combination enables us to evaluate technologies rigorously while also identifying novel applications to support the warfighter in ways that may not yet be fully realized,” Lonergan added.

BOLT-Data and Analysis Collection system

During large-scale experiments like Cyber Quest and Project Convergence, where Soldiers test new technologies in realistic environments, FCC Cyber CDID collects Soldier feedback and integrates it into requirements, ensuring that future systems are designed for the operational environment, not for the lab.

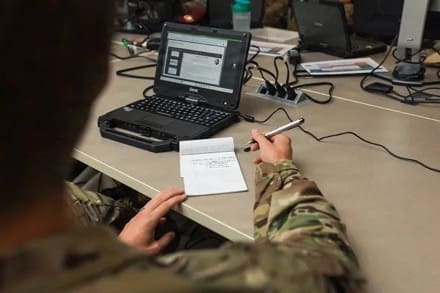

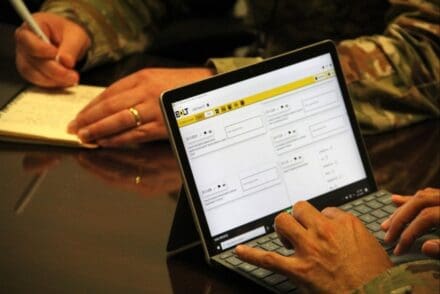

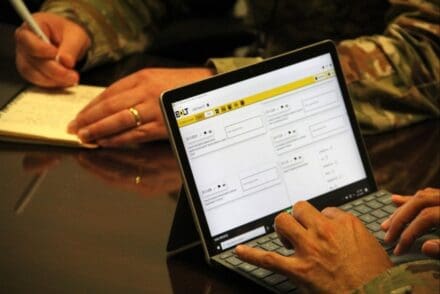

The 75th USARIC Soldiers’ observations were recorded using the FCC Cyber CDID’s Behavior Observation Logging Toolkit, which feeds into the Army’s broader innovation ecosystem.

“By capturing structured feedback through the BOLT digital system, the team provided quantifiable, actionable data on system performance, usability, and operational value,” said Sgt. Santhosh Meenhallimath, innovation analyst, Detachment 3, SG, 75th USARIC.

This data directly informs Army decision-makers, helping prioritize technologies with the highest potential for acquisition, scalability, and impact in future multi-domain operations, according to Pitchford.

The teams used digital tablets and portable micro-laptops with the BOLT software to collect their data, conduct analysis and complete feedback surveys for FCC Cyber CDID.

“The 75th USARIC survey data from the BOLT digital system, our tool for collecting structured feedback, will provide Army decision-makers with detailed insights into Soldier interactions with CQ25 technologies,” Pitchford said. “For instance, their input on interface usability or manual process challenges will highlight which systems enhance effectiveness or need refinement. This data will guide FCC Cyber CDID and Cross-Functional Teams in selecting technologies that reduce the cognitive burden and align with MDO goals, ensuring cost-effective acquisitions and focused innovation.”

This data supports future testing requirements, capability development, and acquisition decisions—ensuring that the technologies invested in are informed by real-world operational needs, added Pitchford.

“As we continue to professionalize data collection during Army experimentation, the contributions made by the subject matter experts from the 75th USARIC have been pivotal,” said U.K. Army Maj. James Harryman, experiment director, CQ25 and military personnel exchange program officer, Cyber Battle Lab, Cyber CDID, “working towards a common goal, I have been impressed by the focus and hard work, which has resulted in an extremely successful result.”

Information Advantage

At CQ25, 75th USARIC Soldiers evaluated a diverse set of technologies spanning advanced networking tools (including Zero Trust architectures), EW, cyber capabilities, and solutions designed to enable information advantage for decision-makers.

“In CQ24, their [75th USARIC Soldiers] assessments shaped the IA construct, and in CQ25, their feedback ensured we prioritized practical, interoperable solutions,” Pitchford said. “This expertise reduces risks in Army modernization by aligning prototypes with operational realities.”

The 75th USARIC evaluation and assessment teams focused on many of the 12 overall technologies at CQ25 including generative AI and how it can speed up information analysis for military decision makers in large scale combat operations and MDO.

“What excites me most are the tools that are bringing generative AI directly into the hands of analysts—reducing the time it takes to gather, synthesize, and analyze information,” said Lonergan, who is a partner at a multinational professional services and consulting firm in his civilian capacity, when not serving in uniform. “These capabilities have the potential to dramatically accelerate the delivery of actionable recommendations to commanders, enabling faster, more informed decisions in complex operational environments.”

The THiEF System

One technology tested and evaluated at CQ25 by the 75th USARIC team was the Tactical Handheld Emitter Finder, a portable system that uses radio direction finding sensors to monitor radio channel(s), or radio frequency spectrum. The THiEF system test/evaluation lane was operated by Army Staff Sgt. Zacharias Bolton, EW noncommissioned officer, 1st Infantry Division.

“I am out here at Cyber Quest to test and experiment with the new technology that the Army is interested in and how it can play a role in electromagnetic warfare, in future operations,” Bolton said.

Interacting with the 75th USARIC team has been a good experience, Bolton added.

“They ask questions on what we think about the technology that is out here and our feedback on future equipment with electromagnetic warfare,” said Bolton.

M.O.T.T.

During the first week of CQ25 another innovative technology evaluated by the 75th USARIC team was the Multi-Orbit Tactical Terminal: multi-orbit connectivity.

Sgt. 1st Class Michael Perry, innovation noncommissioned officer, digital engineer, and Chief Warrant Officer 3 Nicholas Chadwick, innovation digital engineer, both with Detachment 5, Support Group, 75th USARIC entered survey assessment and evaluation data about M.O.T.T. satellite communications.

“Our task was to put the M.O.T.T. through test and evaluation runs on an austere test track complete with tree top and terrain obstructions, and inclement weather [heavy rainstorms] to record and observe data that answer specific questions for the Army capability managers for network & switch,” said Chadwick.

As part of CQ25 testing, Perry and Chadwick entered the M.O.T.T. data for on-the-move lower earth orbit and geosynchronous earth orbit dual configurable ground station transceivers for enhanced and resilient network primary alternate contingency emergency technology into BOLT hand-held tablets from SATCOM panels mounted on the roof of an SUV.

“These assist the Army Capability Managers to develop realistic requirements based on observed, measured (quantitative), and qualitative data including how junior Signal Soldiers briefly trained on the technology are able to operate and understand the technology,” said Chadwick, who works as a senior solutions architect for AI, cloud and data management in his civilian career. “This provides insights into level of effort for training and ease of use.”

TReX and C-sUAS

CQ25 included an operational evaluation of diverse EW capabilities including a radio frequency emulator called Threat Representative Environment X.

“It stood out not only for its ability to generate a wide range of complex signals – such as frequency-hopping burst transmission and GPS spoofing waveforms- which are representative of real-world adversarial threats,” said Meenhallimath. “It also enables other EW technologies to test, train and adapt their detection capabilities. With further integration of AI/ML, TReX holds strong potential to enhance the Army’s ability to emulate complex electromagnetic threats, making it a valuable asset for both training and operational readiness.”

Meenhallimath, who has a master’s degree in computer applications and works as a cloud data architect in his civilian capacity when not serving in the Army Reserve, said CQ25 was also an opportunity for rapid adaptability of EW to evolving threats.

“The [CQ25] experiment demonstrated how tools like TReX and AI/ML [machine learning] based spectrum systems can work together to form a functional and adaptable C-sUAS [counter-small unmanned aerial systems] solution, highlighting the value of combined capabilities in real-world scenarios,” said Meenhallimath.

The intention of using fixed/semi-fixed, mounted or handheld C-sUAS is to defeat or disable drones through detection, tracking and identification.

According to a 2019 Defense Information Systems Agency’s fiscal year 2020 Army Programs C-sUAS executive summary: “common methods for detecting sUAS included radars, radio frequency scanners and electro-optical or infrared cameras.

“Common defeat methods include jamming the sUAS RF control or video link; jamming the Global Navigation Satellite System signals or destroying the sUAS using a kinetic mechanism, such as lasers, projectiles or an intercepting sUAS,” reads the 2019 DISA FY20 Army Programs C-sUAS executive summary.

“CQ25 reinforced the importance of systems that can quickly adjust to novel signal-behaviors,” said Meenhallimath, “whether through manual configuration or model updated in AI-based platforms to remain effective in contested electromagnetic environments.”

CQ going forward

Going forward, according to CQ25 host-the Army CBL, part of now T2COM’s FCC Cyber CDID, future Cyber Quest experiments will be assumed into Army-wide experimentation events like Project Convergence.

Training and education under the new T2COM are tightly integrated with modernization. Soldiers are trained not only to master today’s tasks but also to adapt to tomorrow’s fight.

This includes exposure to emerging capabilities – for example, Soldiers in training pipelines may operate a c-UASs or AI-enabled C2 platforms being tested in Project Convergence.

“Their [75th USARIC] evaluations are vital because their Soldiers, with dual civilian-military expertise, offer unique insights into technology usability and resilience in contested environments,” Pitchford said.

By merging training with futures and doctrine, T2COM accelerates the cycle from concept to training to fielding. Army and Army Reserve Soldiers’ training pipelines are synchronized with modernization timelines, ensuring skill development and readiness matched to the current battlefield.

Regarding previous CQ-tested technologies acquired over the last 4–5 cycles (2020–2024), our experiments inform requirements and as such technologies are intentionally lower technology readiness levels and not yet ready for full-rate production, he added.

“To be clear no technology here is in its final form,” Pitchford said. “We are only attempting to inform and develop Army future requirements and there are no acquisition decisions being made, real or implied because of our findings out of Cyber Quest. The results from Cyber Quest do not directly trigger procurement after the event.”

Key Takeaways: “Innovate in real time”

One of the key takeaways is the utility of bringing a multidisciplinary team to evaluate emerging technologies, said Lonergan, who works as a partner at a multinational professional services firm in his civilian career.

“This was my first time attending Cyber Quest, and it was a great opportunity to evaluate emerging EW technologies and see the growing integration of AI/ML, a clear sign that the Army is moving in the right direction toward modern, adaptive capabilities,” said Meenhallimath. “It was valuable to work alongside other Army components, industry partners and stakeholders, fostering a shared understanding of operational needs and tech maturity.”

The 75th USARIC evaluations are critical in bridging the gap between concept and combat – bringing a user-centric, field-informed perspective to Army modernization efforts, Pitchford added.

“By leveraging a diverse range of skill sets—from cyber and signal to industry and academia—we’re able to identify novel use cases, challenges, and opportunities, and envision how these technologies might be applied across a variety of operational environments, Lonergan said.

“Another important insight is that innovation doesn’t happen organically—it requires deliberate effort across the entire ecosystem, from the front lines to research labs,” Lonergan said. “Experiments like Cyber Quest are critical because they give us the opportunity to explore and refine new capabilities in a controlled environment, so we can reduce the need to innovate in real time on the battlefield and keep the focus where it belongs: on success in mission execution.”

Editor’s Note: The 75th United States Army Reserve Innovation Command enables continuous transformation across the Army’s innovation operational environment by way of a structured innovation lifecycle process to shape requirements in support of a broad range of DOTMLPF-P solutions. The 75th USARIC leverages their unique blend of civilian acquired skills to synchronize continuous transformation efforts across the Army Reserve, ensuring innovation efforts are deliberate, resourced and operationally relevant to Army priorities. For more information about the 75th U.S. Army Reserve Innovation Command, visit www.usar.army.mil/75thIC/ or www.innovation.army.mil/.

Story by MSG Matthew Chlosta

75th US Army Reserve Innovation Command