Marine Corps Base Quantico, Va. —

As the world continues its march into an era of great power conflict, modern warfare is increasingly defined by rapid technological advancements, contested logistics, and the need for resilient communications. Today, reliable connectivity not only enables operations—but rather is the backbone of warfighting, spanning multiple technologies and frequencies to ensure coordination, adaptability, and success, even deep behind enemy lines.

In preparation for this new operational reality, the Marine Corps is advancing Force Design, its comprehensive blueprint for modernization. This effort emphasizes decentralization, agility, and the ability to sustain operations in contested domains.

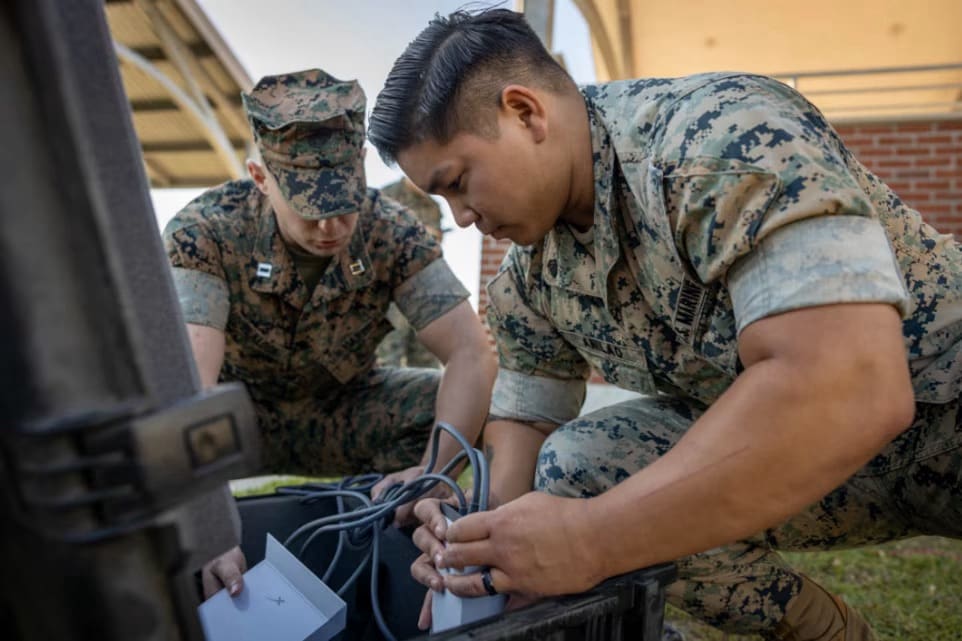

At the forefront of this modernization effort is the Satellite Communication Agile Reachback (SCAR) program. Overseen by MARCORSYSCOM’s Program Manager Tactical Communications and Electromagnetic Warfare Systems and Product Manager High Capacity Communications, SCAR harnesses commercial terminals to deliver wideband satellite connectivity, specifically tailored to the needs of the Marine Corps.

“SCAR is about providing Marines with the connectivity they need to operate effectively in contested environments,” said Jacob Menders, SCAR project officer. “By leveraging existing commercially available technology, we’re not only enhancing communication reliability but also ensuring the flexibility and resilience required for distributed operations. This system was designed with the warfighter in mind, combining cutting-edge technology with the practicality needed to meet the demands of modern battlefields.”

SCAR’s origins lie in the ingenuity of forward-deployed Marines, who began purchasing commercial terminals with unit funds to address gaps in legacy satellite systems. Recognizing the potential of this off-the-shelf solution—and keeping an ear to the ground for warfighter feedback– the Program Office stepped in to formalize and scale the capability, ensuring it would be standardized, sustained, and cost-effective across the force.

To accelerate delivery, the SCAR team partnered with the Navy to leverage its proven Satellite Terminal (transportable) Non-Geostationary (STNG) program. This collaboration, which utilized an existing contract vehicle, saved the Marine Corps between nine to twelve months of acquisition time, demonstrating the value of inter-service partnerships and the importance of rapid, industry-driven solutions to meet the demands of modern warfare.

SCAR’s implementation is structured in phases, ensuring immediate benefits while allowing for future enhancements. Phase one will begin in the second quarter of FY25 with the fielding of SCAR terminals to expeditionary forces. These terminals, designed for plug-and-play functionality, require minimal training and offer instant access to resilient, high-speed communications in contested and remote environments. For expeditionary operations aligned with the operational posture, SCAR provides a critical capability to maintain connectivity and coordination behind enemy lines.

Future phases will build on this foundation. By FY26, SCAR will expand to include transport-layer diversity and multi-vendor competition, ensuring the system remains resilient and adaptable to evolving threats. The long-term vision includes developing multi-band, multi-orbit terminals capable of operating across various satellite constellations, delivering unmatched flexibility. This phased approach ensures SCAR evolves alongside the Marine Corps’ broader modernization efforts, maintaining its relevance in the face of rapidly changing technologies and adversarial capabilities.

According to Dr. Tarah Goggins, WSATCOM Team Lead, “Geostationary satellites operate as static points in orbit. You target one satellite for communication, and while it provides access, it’s a single, fixed point. If that satellite is taken out, communication is lost entirely. With multiple satellites in motion, they offer enhanced security and redundancy. This ensures Marines can maintain strong, continuous communication, even while on the move, by dynamically accessing different satellites as needed.”

In a June 2023 statement, the Pentagon noted: “We continue to work with a range of global partners to ensure Ukraine has the resilient satellite and communication capabilities they need. Satellite communications constitute a vital layer in Ukraine’s overall communications network and the department contracts with Starlink for services of this type.”

Ultimately, the SCAR program embodies the Corps’ commitment to modernization, adaptability, and warfighter-centric solutions. By addressing immediate communication gaps with cutting-edge commercial technology and leveraging inter-service partnerships like the Navy’s STtNG program, acquisition professionals from MARCORSYSCOM’s PM TCE and PdM High Capacity Communications ensure the warfighter can operate effectively in contested environments and stay ahead of evolving threats.

The lessons learned from operational environments highlight the decisive role connectivity plays in modern warfare, and will seamlessly translate into future littoral environments. As the Marine Corps fields SCAR and continues to refine it in the coming years, the program will remain a cornerstone of the broader Force Design effort—ensuring Marines are equipped to fight and win in an era defined by great power competition.

By Johannes Schmidt, MCSC Office of Public Affairs and Communication | Marine Corps Systems Command